Double Shaft Shredder: An Efficient Waste Management Solution

In the realm of waste management and recycling, the double shaft shredder stands out as a highly efficient and versatile machine designed to handle a wide range of materials. This robust equipment is engineered to reduce large, bulky items into smaller, more manageable pieces, making it an indispensable tool in industries such as waste processing, recycling, woodworking, and even in the disposal of confidential documents.

Design and Construction

At its core, a double shaft shredder features two parallel shafts equipped with a series of cutting blades or teeth. These shafts rotate in opposite directions, creating a powerful shearing action that effectively tears apart the material fed into the machine. The design ensures that even the toughest and most resilient materials are reduced to the desired size and consistency.

Application of Double Shaft Shredder

The double shaft shredder is a versatile machine with a wide range of applications in various industries. Its ability to handle different types of materials and reduce them to smaller particles makes it an indispensable tool in waste management, recycling, and other related fields.

1, Waste Management: In municipal and industrial waste management, double shaft shredders are used to reduce the volume of solid waste, making it easier to transport and dispose of. They can handle a variety of waste materials, including household waste, construction debris, and industrial byproducts.

2, Recycling: Double shaft shredders play a crucial role in the recycling industry. They can process a wide range of recyclable materials such as paper, cardboard, plastics, metals, and electronic waste. By reducing these materials to smaller particles, they facilitate the subsequent recycling processes and improve the efficiency of material recovery.

3,Wood Processing: In the woodworking industry, double shaft shredders are used to shred wood waste, including pallets, crates, and offcuts. This not only reduces waste volume but also allows for the recovery and reuse of valuable wood fibers.

4, Agricultural Waste Management: Agricultural residues such as straw, corn stalks, and other crop waste can be efficiently shredded using a double shaft shredder. This helps in the management and utilization of agricultural waste, promoting sustainability in farming practices.

5, Confidential Document Destruction: Double shaft shredders are also used for the secure destruction of confidential documents. Their powerful shredding capability ensures that sensitive information is completely destroyed, providing peace of mind for businesses and organizations.

6, Specialty Applications: In addition to the above, double shaft shredders can be customized for specialty applications such as shredding tires, textiles, and other materials that require specific shredding techniques such as shredding animal bones, fur and fat, etc.

The double shaft shredder is a powerful and versatile machine that offers many advantages for material shredding applications.

1,Versatility

The double shaft shredder can handle a wide range of materials, including plastics, metals, wood, paper, cardboard, and more. This versatility makes it a valuable asset in various industries.

2,High Efficiency

The machine operates with high efficiency, capable of processing large volumes of material quickly. This helps to reduce processing times and increase overall productivity.

3,Robust Construction

The double shaft shredder is built with durable materials and robust construction, making it capable of withstanding the rigors of heavy-duty shredding applications.

4,Low Speed, High Torque

The design of the double shaft shredder features low-speed, high-torque rotors. This allows it to effectively process tough materials that might be difficult for other shredders to handle.

5,Customization Options

The machine can be customized to meet specific requirements, such as different cutting blade configurations and motor options. This flexibility makes it adaptable to various applications.

6,Energy Saving

Some models of double shaft shredders are designed to be energy-efficient, reducing operational costs and environmental impact.

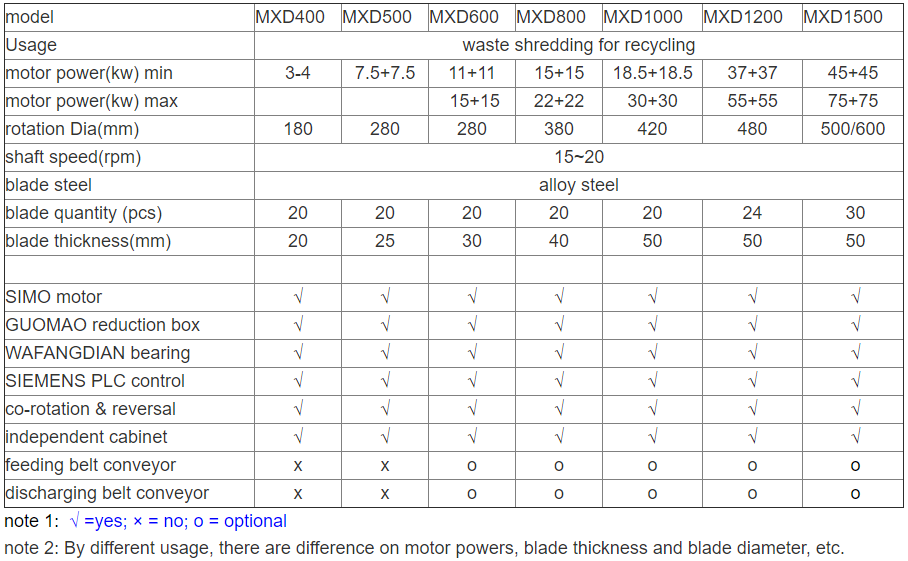

Models of double shaft shredder in MG Machinery:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007, for example, Japan, Vietnam, Indonesia Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Geogia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.