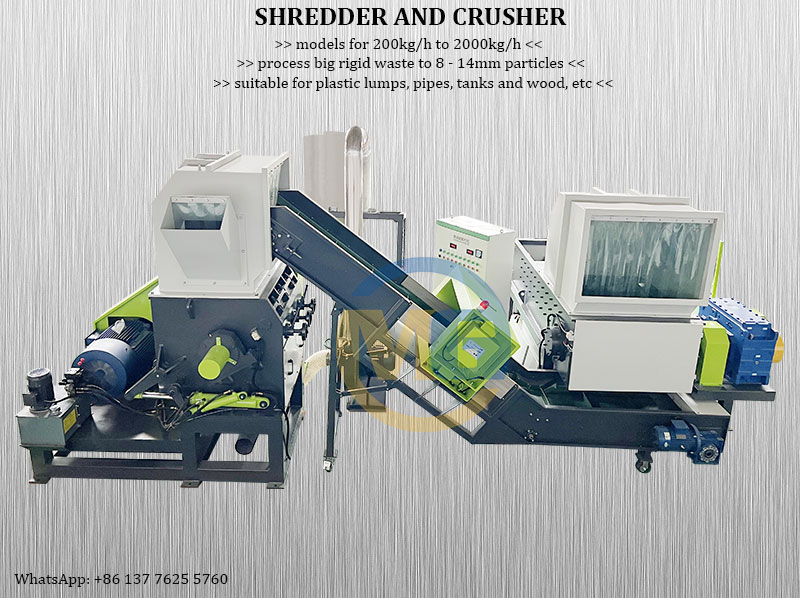

Shredder Crusher Line for Hard Plastic Waste Recycling.

In the realm of waste management and recycling, the shredder crusher line has emerged as a game-changer for hard plastic waste

recycling. This advanced production line is specifically designed to handle the challenges posed by tough, durable plastics,

transforming them into reusable materials with minimal cost and maximum efficiency.

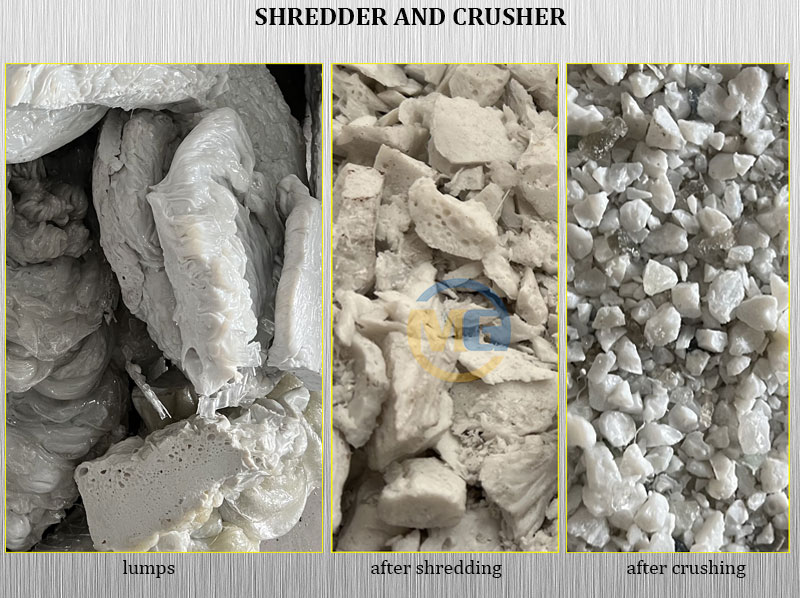

No matter how big the hard plastic waste is, this shredder crusher line can process it to 8-14mm particles.

The shredder crusher line comprises several key components, including:

1, Single Shaft Shredder: This powerful shredder machine breaks down large pieces of hard plastic into manageable chunks,

preparing them for further processing.

2, Secondary Crusher: This stage further reduces the size of the plastic particles, ensuring a consistent and uniform output, to meet

the reproduction requirement.

3, Belt Conveyors: usually one is used to transport the hard plastic into the shredder, and the other one is for conveying shredded

plastic into the crusher machine. They are used for maintaining a smooth and continuous workflow.

4, Cyclone System: By using the blower force, to collect the crushed plastic particles and send them into a storage silo.

5, Screening and Separating System(optional): This component sorts the final plastic particles according to size, removing any

unwanted materials. But it not the necessary unit in the shredder crusher line.

Application Range:

The shredder crusher line is versatile and can be applied to a wide range of hard plastics, including but not limited to:

Acrylonitrile butadiene styrene (ABS)

Polyethylene terephthalate (PET)

Polyvinyl chloride (PVC)

Polypropylene (PP)

Polyethylene (PE)

Polystyrene (PS)

This makes it an ideal solution for recycling centers, manufacturing plants, and other industries that generate significant amounts of

hard plastic waste.

Advantages of the Shredder Crusher Line from MG machinery company:

1, High Efficiency: The line is designed for maximum throughput, allowing you to process large volumes of hard plastic waste in a short amount of time.

2, Cost-Effective: By reducing waste and transforming it into reusable materials, the shredder crusher line can help you save on disposal costs and generate additional revenue through the sale of recycled plastic.

3, Sustainable: By promoting the recycling of hard plastics, the line contributes to environmental sustainability and reduces the burden on landfills and incineration facilities.

4, Durability: Built with high-quality materials and precision engineering, the shredder crusher line is designed to withstand the rigors of daily use and provide years of reliable service.

5, Customizable: The line can be customized to meet the specific needs of your operation, ensuring that it seamlessly integrates into your existing recycling or manufacturing process.

Etc.

The shredder crusher line is an essential tool for any organization committed to hard plastic waste recycling. Its high efficiency, cost-effectiveness, sustainability, durability, and customizability make it an invaluable asset for promoting a greener, more sustainable future.

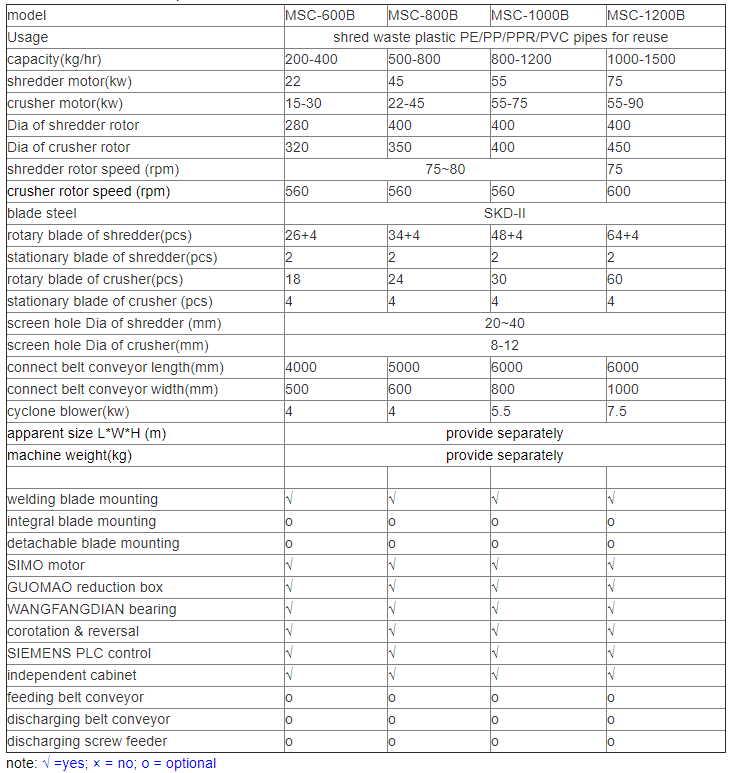

Models of shredder crusher production line in MG Machinery:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

6, careful machine loading and fixing work in container.

7, dispatch engineer for after sale service in your company on time

8, training for machine and operation.

9, technology support.

etc.

Our plastic recycling and extrusion machines have been exported to many countries, for example, Japan, Vietnam, Indonesia Thailand, Malaysia, India, Nepal, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Geogia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.