Shredding Crushing Machine: A Powerhouse for Hard Waste Plastic Recycling

The strong shredding crushing machine is designed specifically for the challenging task of recycling hard waste plastics. This machine is engineered with precision and built to last, combining robust construction with cutting-edge technology to deliver unparalleled performance.

The shredding crushing machine means it include shredder design and crusher design on the same machine. The shredder part is usually a single shaft shredder type for coarse crushing of big and tough hard plastic waste, like the plastic lumps. And the crusher is used for fine crushing directly under the shredder. For any big size hard plastic waste, it can be process into 8-14mm particles by one time working.

The shredding crushing machine features a sturdy frame made from high-quality materials, ensuring stability and durability during operation. Its powerful motors drive the shredding and crushing mechanisms, which are designed to handle even the toughest of plastic materials. The machine is equipped with sharp, durable blades that effortlessly cut through hard plastics, reducing them to manageable size for further processing.

In addition, the shredding crushing machine incorporates advanced safety features to protect operators and prevent accidents. Its intuitive control panel allows for easy operation and monitoring, ensuring smooth and efficient recycling processes.

Application Range:

Our shredding crushing machine is versatile and suitable for a wide range of hard waste plastic recycling applications. It can be used in recycling facilities to process large volumes of plastic waste, transforming it into valuable raw material for reprocessing. The machine is also ideal for waste management companies, plastic processors, and manufacturers looking to reduce their plastic waste and promote sustainability.

Whether you're dealing with thick plastic lumps, pipes containers, and automotive parts, or other industrial plastic waste, our shredding crushing machine can handle it all. Its efficient design and powerful performance make it the perfect choice for any hard waste plastic recycling operation.

In MG Machinery company, our shredding crushing machine is a reliable, efficient, and sustainable solution for hard waste plastic recycling. With its robust design, advanced technology, and wide range of applications, it's the ideal choice for any business looking to reduce their plastic waste and promote a greener future.

The shredding crushing machine offers numerous advantages in the field of waste hard plastic recycling, making it an indispensable

tool for businesses and recycling facilities.

1, High Efficiency and Productivity

High-Speed Processing: These machines are designed to process hard plastics at fast speed, significantly increasing the throughput

of waste plastic.

Continuous Operation: Many models are capable of continuous operation, minimizing downtime and maximizing production capacity.

2, Robust and Durable Design

Heavy-Duty Construction: Made from high-quality materials, these machines are built to withstand the rigors of shredding and crushing

hard plastics.

Long-lasting Blades: Equipped with durable blades, the machines maintain sharp cutting edges over extended periods, reducing the

need for frequent replacement.

3, Wide Range of Applications:

Versatile Processing: Capable of handling a wide variety of hard plastic materials, including plastic pipes, lumps drums, containers,

pallets and industrial waste, etc.

Multi-industry Use: Suitable for use in the plastics, automotive, construction, and packaging industries, among others.

4, Enhanced Safety Features:

Operator Protection: Equipped with safety guards and emergency stop buttons to protect operators from potential hazards.

Automated Controls: Intuitive control panels and automated systems minimize the risk of operator error.

5, Cost-Effective:

Low Maintenance Costs: With reliable performance and long-lasting components, these machines require minimal maintenance.

Reduced Labor Costs: Automated processes reduce the need for manual handling, lowering labor costs.

6, Energy Efficiency:

Energy-Saving Technology: Some models incorporate energy-efficient motors and drive systems, reducing operational costs.

Optimized Performance: Designed for optimal energy usage, these machines minimize energy waste.

7, High-Quality Output:

Uniform Particle Size: Capable of producing uniformly sized plastic particles, suitable for further processing or reuse.

Low Dust Generation: Advanced dust control systems minimize the generation of dust and fines during operation.

8, Reliable Performance:

Consistent Results: With reliable performance and consistent output, these machines ensure high-quality recycled materials.

Low Downtime: Regular operation with minimal downtime maximizes productivity and efficiency.

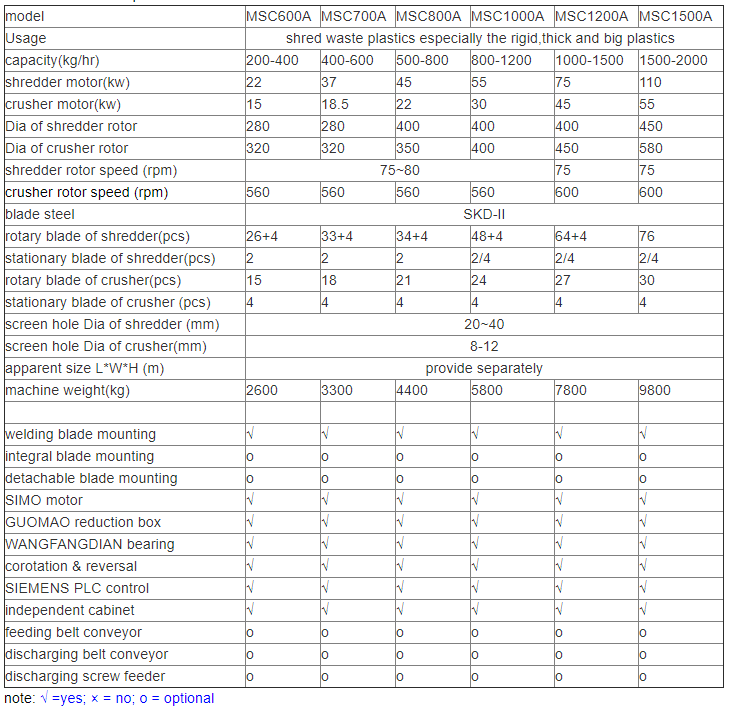

Models of shredding crushing machine in MG Machinery:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.