Plastic Squeezer Machine for drying and agglomerating pelletizing waste plastic films and woven Bags, etc.

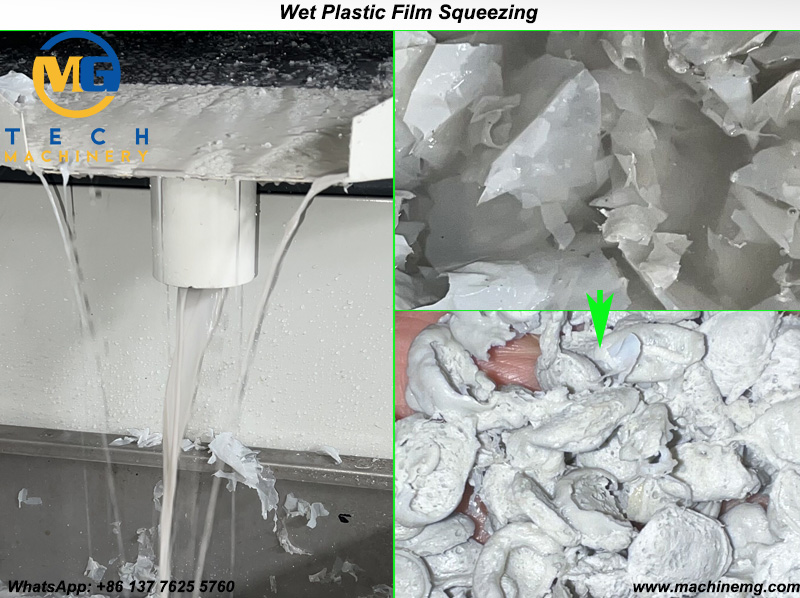

The Plastic Squeezer Machine is an advanced industrial equipment designed for efficient drying and pelletizing of waste wet plastic

films and woven bags. This squeezing machine is an essential solution for recycling facilities aiming to squeeze out moisture, reduce

waste volume, save energy, and transform plastic waste into reusable agglomerated pellets for further manufacturing processes.

Key Features of our plastic squeezer machine:

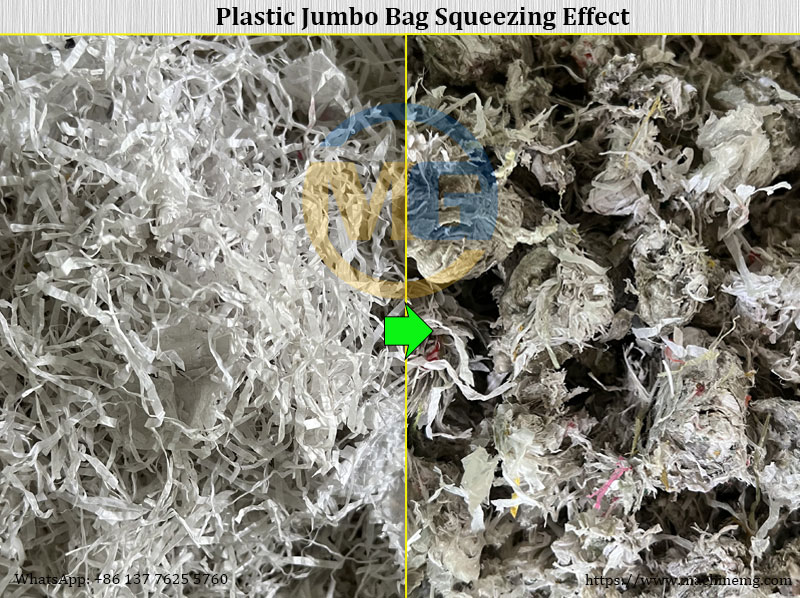

1. Efficient Drying System: The machine integrates a high-performance squeezing mechanism that removes moisture from plastic films

and woven bags

2. Agglomerating Pelletizing Functionality:

After squeezing the water, the machine compacts and processes the plastic materials into agglomerated pellets, ready for reuse in

plastic production.

3. Versatile Application:

Suitable for a wide range of plastic materials, including LDPE, HDPE, PP films, PP raffia materials from jumbo bags and woven bags,

as well as plastic labels mixing with some flakes, making it ideal for diverse recycling needs.

4. Eco-Friendly Design:

By recycling plastic waste into reusable materials, the machine supports sustainable practices and reduces environmental impact.

5. Compact and Space-Saving: Designed with a compact structure, the machine maximizes workspace efficiency while delivering

high output.

6. Durable and Low Maintenance: Built with robust materials and advanced technology, the squeezer machine ensures long-lasting

performance with minimal maintenance requirements.

7. User-Friendly Interface: Equipped with an intuitive control system, the machine is easy to operate, ensuring smooth and efficient

workflow.

Applications:

1, Recycling plastic films from packaging, agriculture, and industrial waste.

2, Processing woven bags used in food, chemical, and construction industries.

3, Transforming plastic waste into agglomerating pellets for manufacturing new products.

Benefits:

1, Reduces waste volume and transportation costs.

2, Enhances recycling efficiency and material reuse.

3, Supports eco-friendly and sustainable practices.

4, Lowers operational costs with energy-efficient performance.

The Plastic Squeezer Machine is a reliable and innovative solution for businesses looking to optimize their plastic recycling processes,

reduce environmental impact, and achieve cost-effective operations. Whether for small-scale or industrial use, this machine delivers

exceptional performance and value.

Consists of the plastic squeezer machine

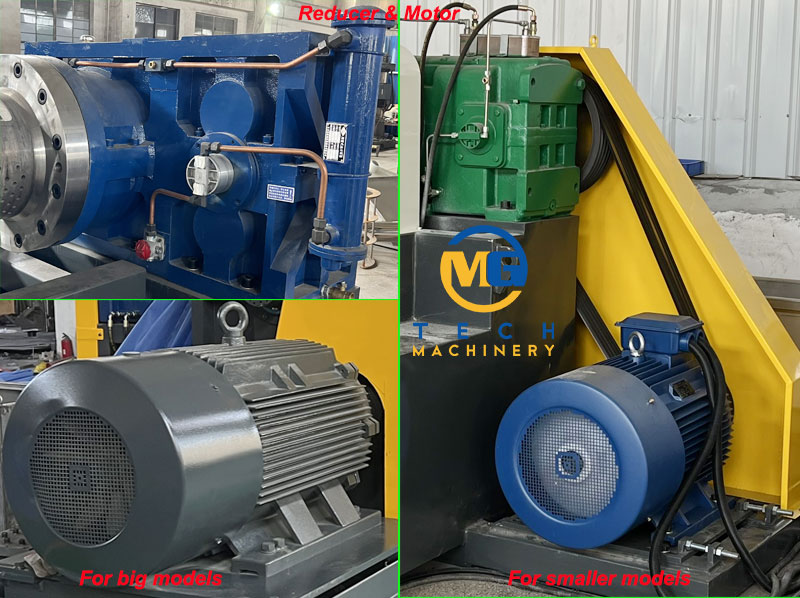

1, Motor and reducer

Powerful motor and reducer are installed on the plastic squeezer for smooth squeezing work. famous brands motors and reducers are used, for example , WN, SIEMENS China, SIMO, JIAMUSI motors, and GUOMAO reducers.

2, Barrel and screw

The barrel and screw are made of alloy 38CrMoAlA steel, with nitriding treatement on the surface, more hardness, durability.

Screw has special design to ensure the smooth feeding of films and bags materials.

Barrel with more thickness, and holes on the wall for drainage quickly while the pressing and squeezing to the films or bags, so that to get the high dewatering result.

3, Heater system for the mold

Cast aluminum heaters is used for heating the mold and transit area of barrel, and use to intelligent meters for temperature set and control.

4, cooling system.

Water cooling system is equipped for reducer and mold head cooling.

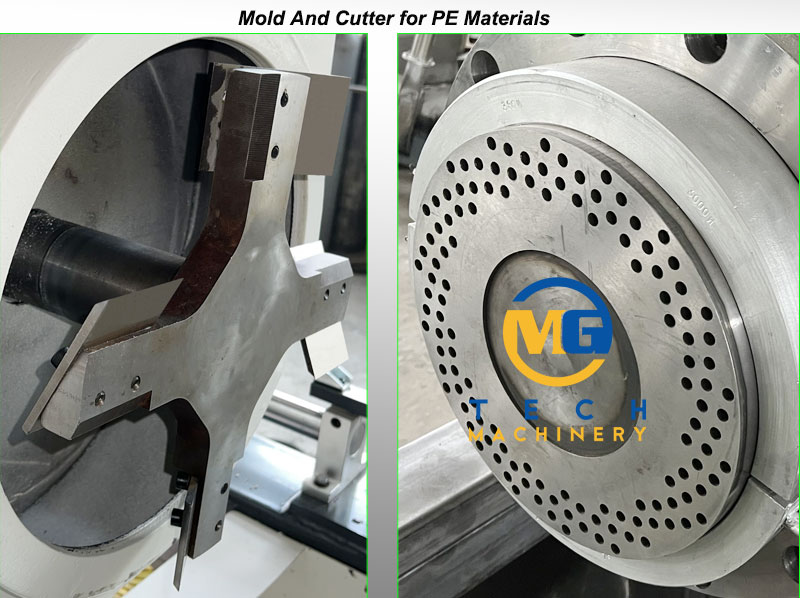

5, pelletizing system.

A perforated mold is installed on the head of the plastic suqeezer machine, and a cutter with 2pcs or 4 pcs blades are matched with the mold for pelletizing. While the plastic materials are squeezed out from the barrel and mold, the cutter cut the strands on the die face immediately into the pellet shape or agglomerated materials, which will drop into the transit silo and are blown into sysclone silo.

For PE and PP materials, the perforated molds are different.

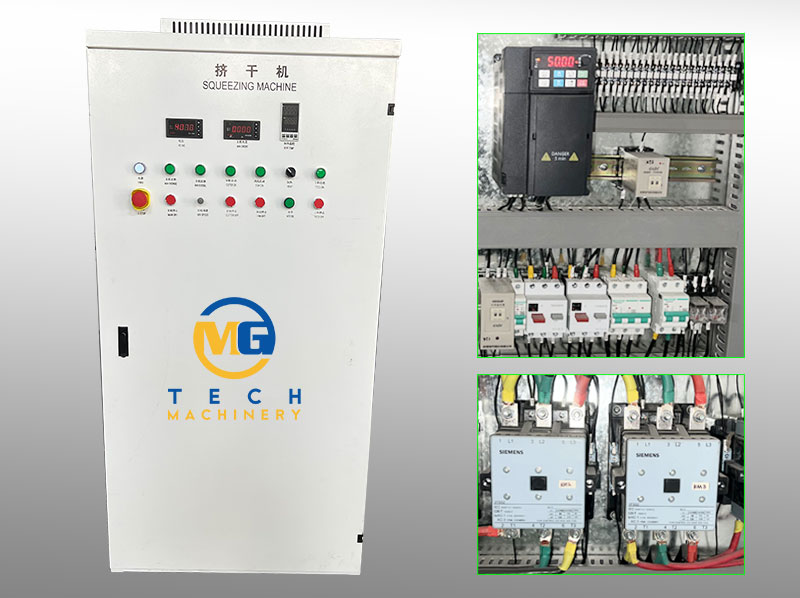

6, control cabinet.

The control cabinet is used for the centralized control of the plastic squeezer machine. Good quality electrical components and parts are used for making the cabinet, for example, SIEMENS contactor, ORMRON temperature meter, Delta or ABB inverters, etc.

It's very easy for the users to set required technical parameters on the panel, for example, rotation speed, temperature value, etc.

The PP PE plastic suqeezer machine can process different wet PP PE films and bags, no limitation on orginal moisture of the plastic materials. But it can make the good result on dewatering and pelletizing of the materials.

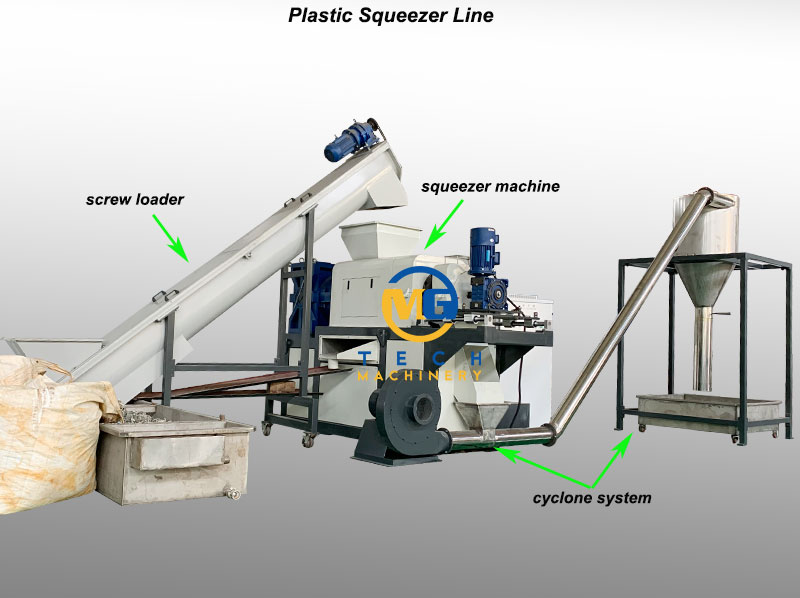

How to feed the materials into the squeezer?

The users can choose the belt conveyor or screw loader to standby the plastic squeezer machine, and it will help to convey the materials into the squeezer from the ground.

Screw loader is more suitable for the materials with high moisture, and the belt conveyor is usualy for the material with less water content.

Flowchart of a plastic squezer line with screw loader:

Please send your enquiry now, We will make response quicky.

Advantage of PP PE plastic squeezer machine in MG Machinery:

1, with different mold designs, Both PP PE films and bags can be squeezed.

2, dewatering and pelletizing functions by one time processing.

3, high dewatering rate, final moisture less than 3~5%.

4, good semi plasticizing function, no effect to material quality in the after process like pelletizing.

5, hard teeth reducer, big torque for squeezing.

6, alloy 38CrMoAlA for making barrel and screw, durability.

7, PLC control, easy operation for parameter set by different materials conditions.

8, low rotation speed, lower noise.

9, heavy structure, steady working.

10, cyclone system for materials discharging, less labor required

11, quality certificate.

etc.

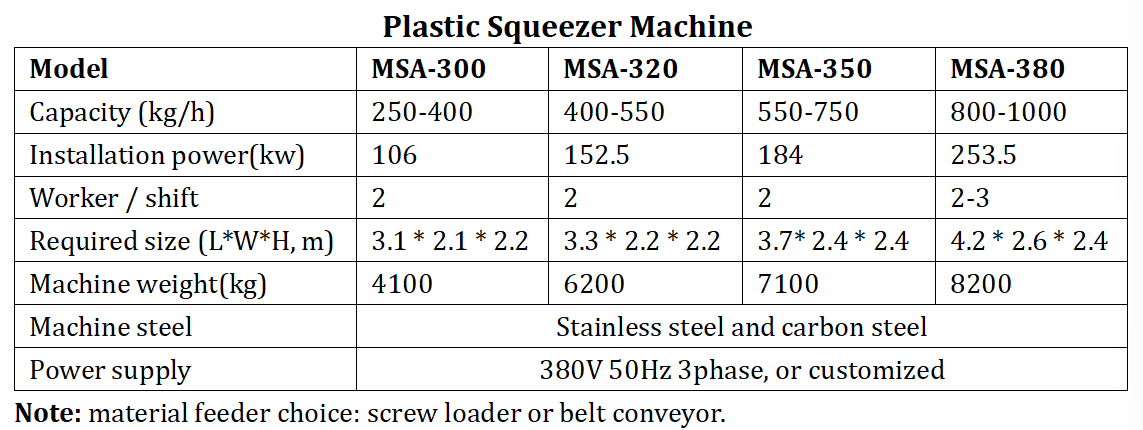

Models of plastic squeezer machine in MG Machinery company:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.