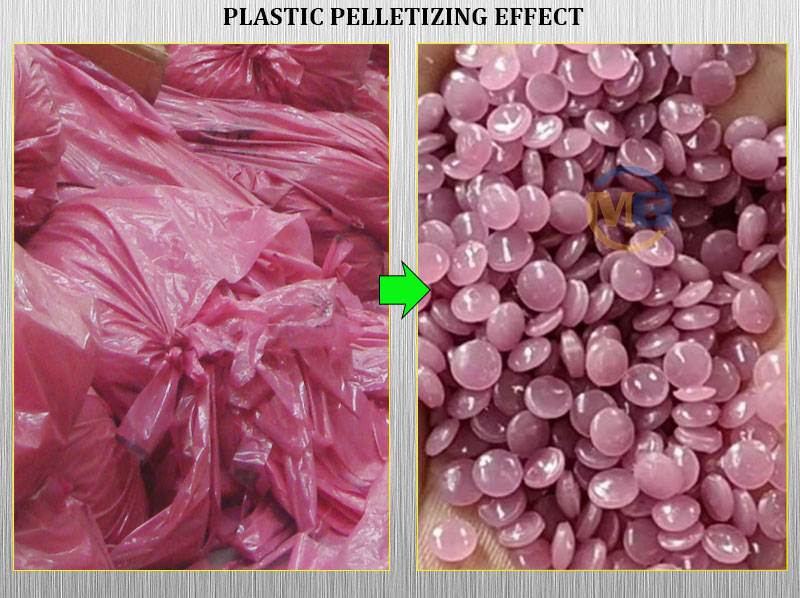

Water Ring Plastic Film Pelletizing Machine, a game-changer in plastic recycling and processing. Mainly for HDPE LDPE and PP waste films and bags.

This innovative Water Ring Plastic Film Pelletizing Machine utilizes a water-cooled cutting chamber to efficiently convert waste plastic films into uniform, high-quality pellets. With its superior cooling system, it ensures minimal heat generation and particle agglomeration, resulting in superior pellet quality.

The Water Ring Pelletizing Machine offers exceptional performance, durability, and ease of use. Upgrade your plastic processing capabilities and embrace sustainable, profitable recycling practices with our cutting-edge Water Ring Plastic Film Pelletizing Machine.

The Water Ring Plastic Film Pelletizing Machine has a wide range of applications, including but not limited to the following areas:

Plastic Recycling Industry: As a core equipment in the plastic recycling industry, this machine efficiently converts waste plastic films into plastic pellets, providing raw materials for subsequent plastic processing.

Plastic Manufacturing Industry: In the plastic manufacturing process, the machine can reprocess scraps, waste materials, etc. into plastic pellets, achieving resource recycling and reducing production costs.

Packaging Materials Industry: For companies producing plastic packaging materials, this machine can recycle and reuse waste plastic packaging materials, reducing resource waste and environmental pollution.

Agriculture Sector: In agricultural production, plastic films are widely used for greenhouse covering, mulching, etc. This machine can recycle and process waste agricultural plastic films into plastic pellets, enabling resource recycling.

Other Industries: Additionally, the machine is applicable to electronics, automotive, household appliances, and other industries for recycling and processing waste plastic films and plastic products.

In summary, the Water Ring Plastic Film Pelletizing Machine is suitable for any occasion where waste plastic films need to be processed and converted into plastic pellets, with broad application prospects and market demand.

The plastic film pelletizing machine is single stage water ring pelletizer type. It includes cutting compactor feeder, single screw extruder, hydraulic net changer, water ring pelletizer, vibration machine, cyclone system and centralized control cabinet.

The processing of the plastic film pelletizing machine is as following:

1, compactor: cut and shrink the big plastic films and feed the materials into extruder automatically.

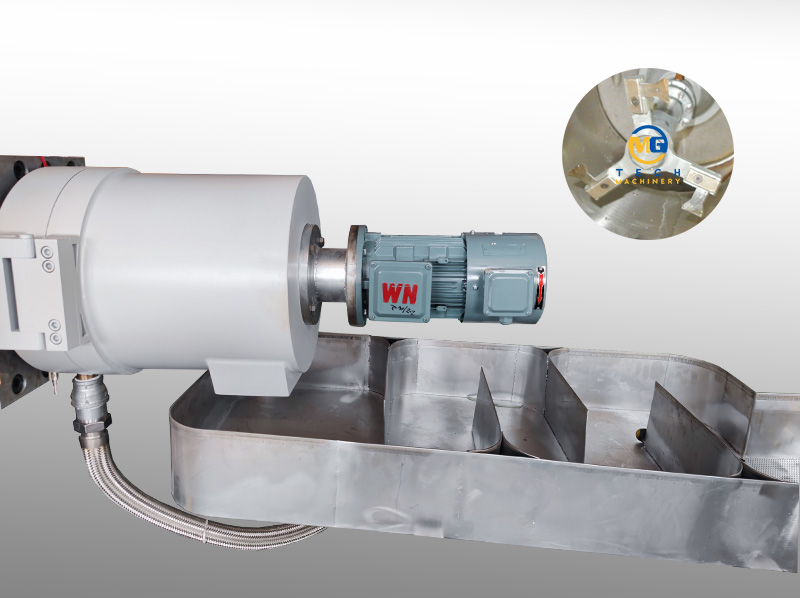

2, single screw extruder: plasticize the materials well and degassing the material.

3, hydraulic net changer: filter out the impurities.

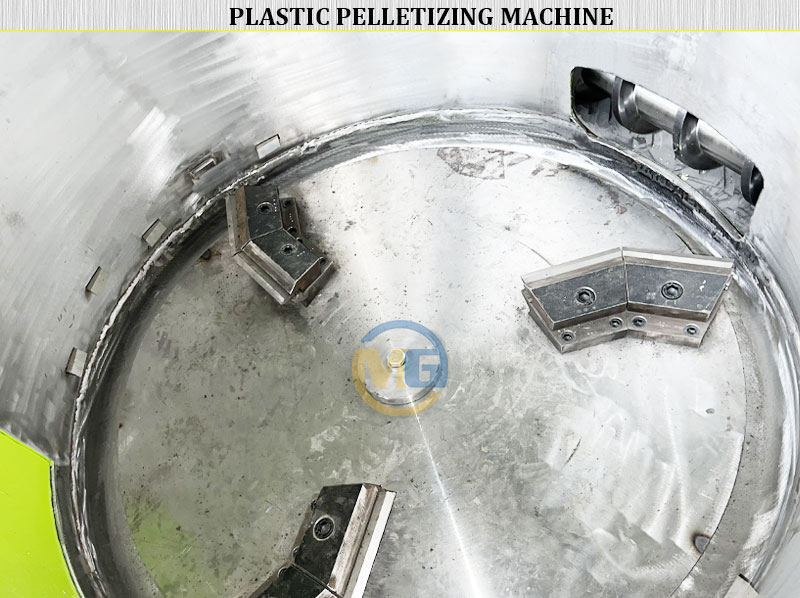

4, water ring cutter: cut plasticized materials into round pellets.

5, vibration machine: classify the pellets and shake off the more water.

6, cyclone system: spin out water content, and convey the pellets into storage silo.

7, centralized control cabinet: control the running of whole plastic pelletizing machine.

Belt conveyor is an auxiliary machine for feeding the plastic films into the compactor.

Advantage of PP PE plastic film pelletizing machine in MG Machinery:

1, special blower working with vibration machine, good dewatering rate.

2, easy operation and maintenance.

3, low power consumption

4, less manpower, high automation.

5, good plasticizing and degassing for materials.

6, 38CrMoAlA barrel and screw with nitrogen procession, wearable, long lifetime.

7, hard teeth reducer, big torque.

8, SIEMENSE or WN motors with ABB inverter, steady running.

9, ceramic heater, even heating result.

10, OMRON temperature meter, precision control.

11, double position hydraulic net changer for alternative working, high efficiency.

12, alloy knives for pelletizing cutter, smooth cutting, long use time.

13, embedded circular water cooling system, good cooling result for die and pellets.

14, strong machine structure.

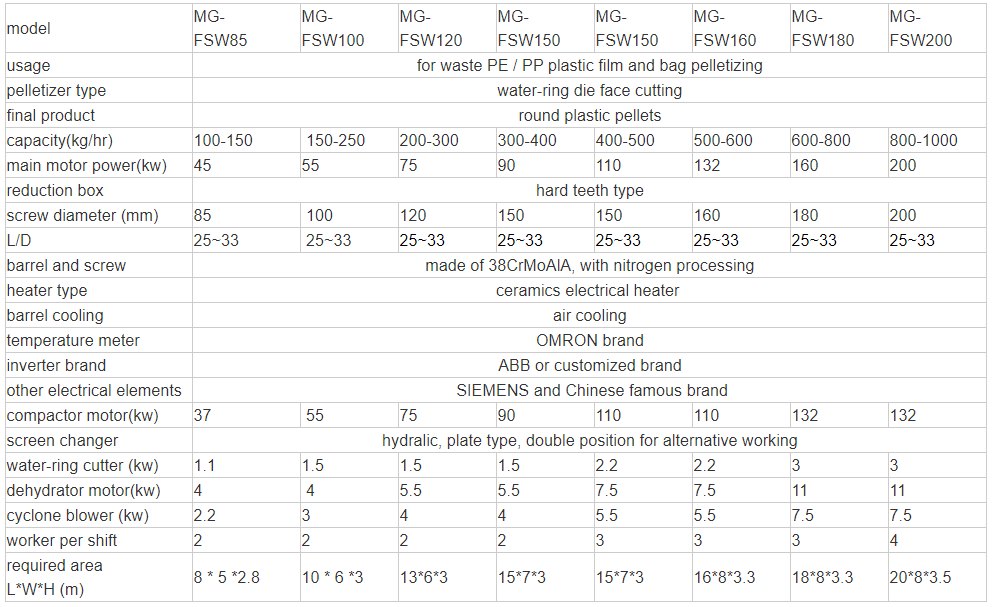

Models of PP PP plastic film pelletizing machine:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007, for example, Japan, Vietnam, Indonesia Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Geogia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.