Double stage water ring plastic film pelletizing machine is used to produce plastic pellets from waste plastic PE films and bags mainly, some parts of waste PP films and bags with lower melt flow index can also be pelletized on the water ring pelletizer. With the compactor feeder, the big film pieces can be fed into the pelletizer directly, film crusher is not necessary to work with this pelletizing machine.

Because the pelletizer design can produce high quality plastic pellets, the double stage water ring pelletizers have been widely used in the recycling factories, plastic films manufacturing factories, other companies who use package films and bags.

Reference video on YouTube video for the double stage water ring PE plastic film pelletizing machine:

https://www.youtube.com/watch?v=Rrdss2GBMq0

The double stage water ring plastic film pelletizing line consists of the following machines:

1, belt conveyor: for feeding the films and bag mateials into the compactor.

2, cutting compactor: It has two functions for crushing the big films into small pieces, and shrinking the films for forced feeding

into the barrel of extruder.

Its' barrel is made of stainless steel 304, and the alloy stationary blades and rotary blades are arranged on the barrel wall and rotation disc with special angles, for efficient cutting.

temperature control is through the thermocouple and temperature meter.

3, two single screw extruders for two steps of plasticizing.

Barrel and screw are made of alloy 38CrMoAlA, screw structure are designed according to the properties of film waste.

Driving system with powerful motor and reducer from famous brands, like WN, SIEMENS BEIDE, GUOMAO, etc.

Cast aluminum heaters with air cooling, and easy to set the temperature on the meters, precise control, avoid material degradation.

Barrel with vacuum degassing system connection, strong vacuum exhausting, improve pellet quality.

4, double position hydraulic screen changer: filtering out the impurities to purify the plastic materials. Usually equip with the plate type double position screen changer on the pelletizing lines.

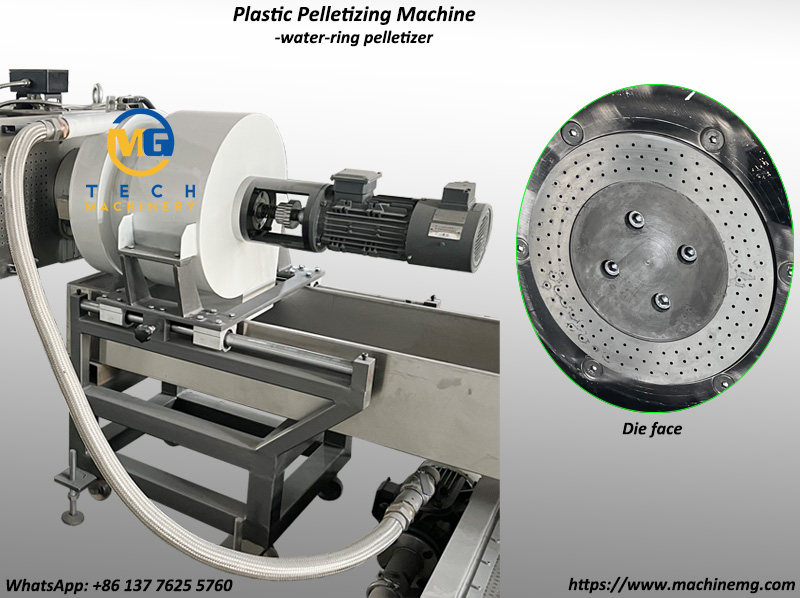

5, water-ring pellet cutter:

Cut the mateials into pellets on the die face, and use water to cooling and flush out the pellets from the water ring pelletizer.

the pelletizing blades are alloy steel, and cover is made of stainless steel.

With the special design of water channel, the water will not contact the die face while the working.

6, centrifugal dewatering machine: it is used to dehdyrate the plastic pellets while the high speed rotation, up to 1500rpm.

The machine body, sieve and paddles are made of stainless steel.

7, vibration sieve:

As usualy, 2 layers or 3 layers model are chosen for classifying the plastic pellets with different sizes, the unqualified pellets can be resend to the extruder for pelletizing again.

8, cyclone silo: As a temporary storage unit for the pellets. the silo and pipeline are made of stainless steel.

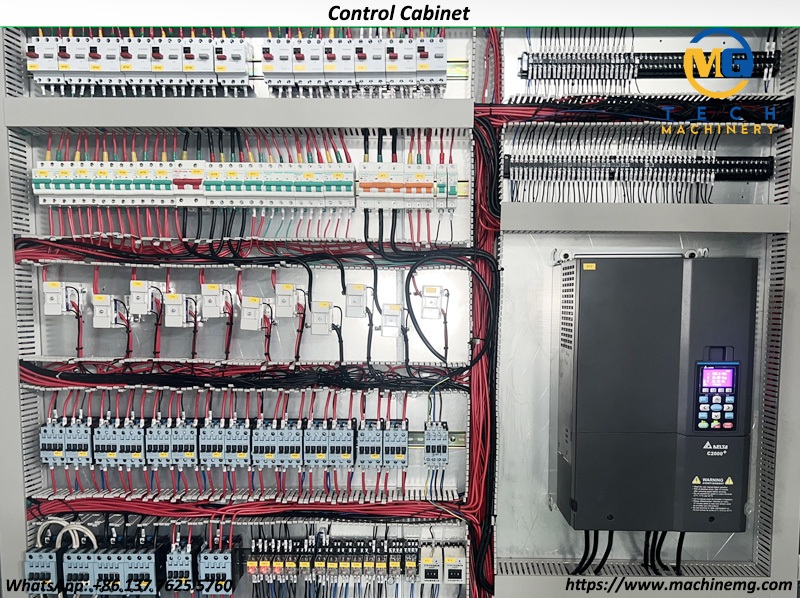

9, centralized control cabinet: the users can set the parameter and control the whole line on the cabinet directly.

Good quality electrical parts are used for making the control cabinet, for example, SIEMENS or SCHNEIDER contractor, ABB or Delta inveters, OMRON temperature meters, etc.

By this water ring plastic film pelletizing line, the printed films can be also pelletized.

Is the plastic pelletizer waht you are looking for? Please send your requirements and waste material conditions, our technical team will guide you to choose the correct model of water ring plastic pelletizing machines and lines.

Advantage of double stage water ring plastic film pelletizing machine in MG Machinery:

1, big film cutting and agglomerating automatically, then force feeding into the extruder directly,

2, special screw design for good plasticizing.

3, strong vacuum exhausting, improve pellet quality.

4, 38CrMoAlA barrel and screw with nitrogen procession, wearable, long lifetime.

5, powerful driving system with famous motor and reducer brands.

6, good quality inverter for motor speed control, for example, ABB, Delta, Invt, etc.

7, cast aluminum heater for fast heating result.

8, precise temperature control by good quality meters, like OMRON brand.

9, double position hydraulic screen changer for alternative working, no stop.

10, alloy knives for pelletizer cutting, smooth cutting.

11, embedded circular water cooling system, good cooling result, and the die face will not contact water while pelletizing.

12, easy operation and maintenance.

13, less labor required.

14, strong machine structure.

15, quality certificate.

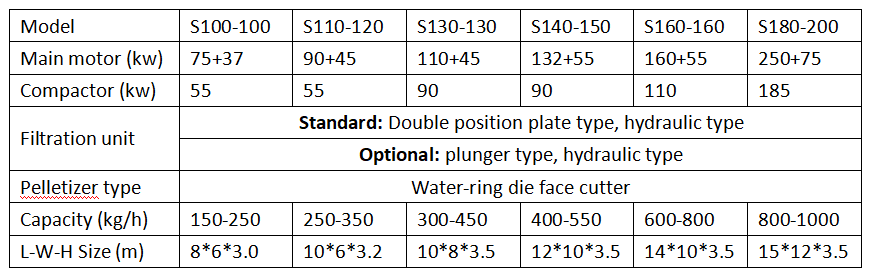

Models of the double stage water ring plastic film pelletizing line:

Other models of plastic pelletizer machine can be customized laso.

Why choose us?

1, we can provide the most suitable pelletizer proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, operation training.

10, technology support.

11, cost price for machine parts replacement if it is necessary all lifetime.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007, for example, Japan, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Ukraine, Serbia, Geogia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.