Double stage plastic pelletizer machine is used to pelletize the waste plastic PP PE films, It includes cut compactor for efficient material feeding, and water ring cutter for smooth pelletizing and good cooling. The double stage plastic pelletizer machine has wide usage in the plastic recycling plants, plastic films manufacturing plants, other plants which use package films and bags.

The PP PE film double stage plastic pelletizer machine includes cutting compactor, 1st and 2nd single screw extruder, double station hydraulic net changer, water ring pellet cutter, centrifugal dewatering machine, vibration machine, cyclone system and centralized control cabinet.

The processing of PP PE film double stage plastic pelletizer:

1, compactor: cut and shrink the big plastic PP PE films and bags directly, then feed the materials automatically into 1st extruder.

2, 1st and 2nd single screw extruder: plasticize the materials well and degassing the material to improve the pellets quality.

3, hydraulic net changer: filter out the impurities.

4, water ring cutter: cut plasticized materials into pellets.

5, vibration machine: classify the pellets and shake off the most water.

6, cyclone system: spin out water content, and convey the pellets into silo for easy package.

7, centralized control cabinet: control the working of plastic pelletizer machine.

Advantage of PP PE film double stage plastic pelletizer machine in MG Machinery:

1, wide usage for kinds of waste plastic PE PP films.

2, month-baby 2 stage extruder for good plasticizing and degassing.

3, 38CrMoAlA barrel and screw with nitrogen procession, wearable, long lifetime.

4, hard teeth reducer, big torque.

5, SIEMENSE or WN motors with ABB inverter, steady running.

6, ceramic heater, even heating result.

7, OMRON temperature meter, precision control.

8, double position hydraulic screen changer for alternative working, high efficiency.

9, alloy knives for pelletizing cutter, smooth cutting, long use time.

10, embedded circular water cooling system, good cooling result for die and pellets.

11, easy operation and maintenance.

12, low power consumption

13, less manpower, high automation.

14, strong machine structure.

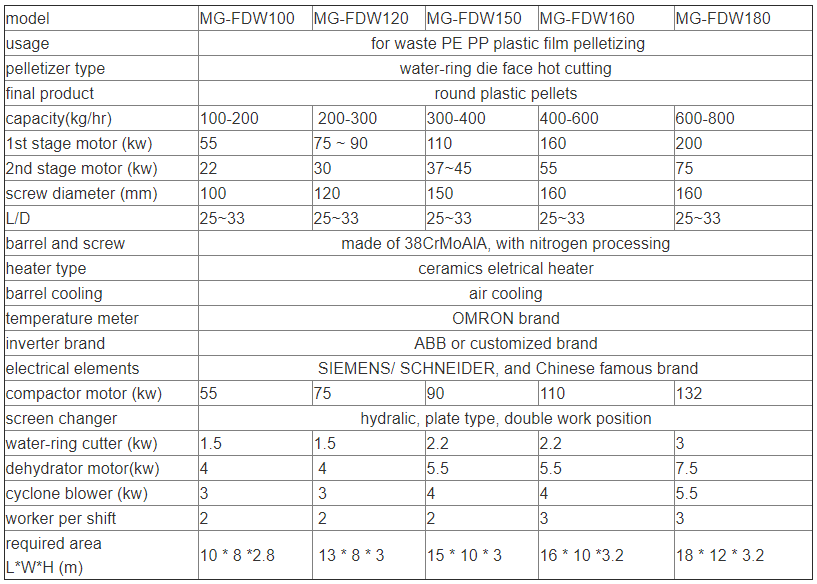

Models of PP PE film double stage water ring plastic pelletizer machine in MG Machinery: