Plastic film grinder machine has heavy structure, it can grind the waste plastic films and bags efficiently by the strong rotor with alloy blades on the V shape holder. As usual, one grinder machine includes the drive motor, main rotor, rotary blades, stationary blades, screen sieve, hopper opening system, water spray unit and grinder body frame. For grinding crushing the tough mateirals such as plastic films and woven bags, a good plastic grinder machine can bring the large output but less power cost.

Application of plastic film grinder machines:

1, package films, agricultural films, greenhouse films, shopping film bags, fresh keeping film bags, garbage bags,

2, PP bags: plastic bags woven bags, jumbo bags, sack bags, hand bags and vest bags, etc.

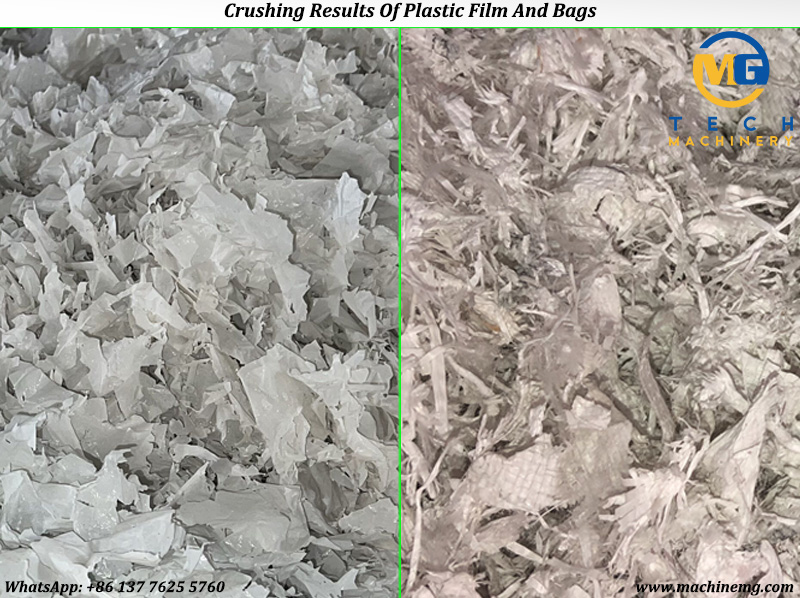

In the plastic film and bag recycling industry, one step is to cut the big film and bags into small piece, and it's very important for the efficient recycling processing such as friction washing and floating washing. And that's the function of the plastic film grinder machines, the large films and bags can be crushed into pigments with indicated sizes by real requirement.

Reference Video on YouTube Channel

1, plastic film grinder with hydraulic hopper opening device and high platform

2, plastic film grinder with mechanical hopper opening device

3, grinder for PP woven bags or jumbo bags

Consist of the plastic film grinder machine

1, rotor and blades

The rotor of grinder is with 5 groups of V shape mounting rows for the rotary blades, It can cut the plastic films and bags into pieces smoothly, but not tear apart the plasticmateials. And It brings also the higher throughput with less power cost.

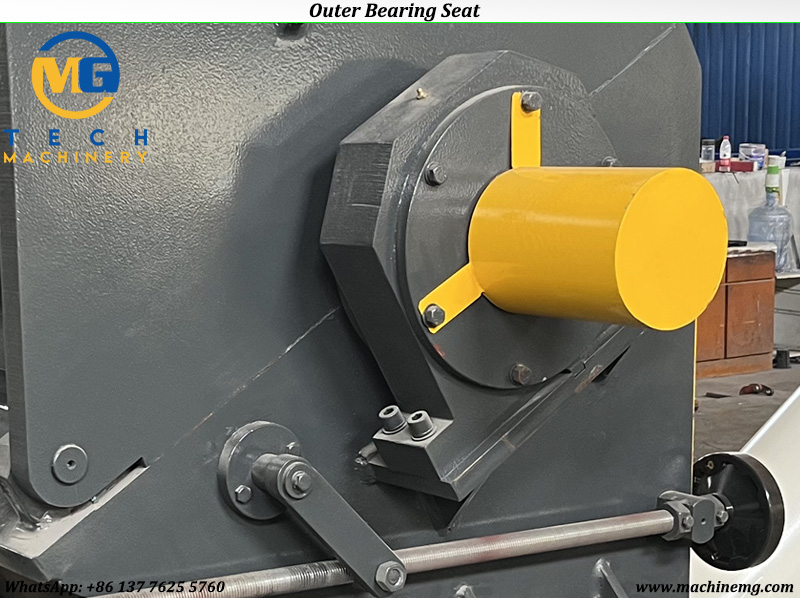

External bearing mounting for the plastic film grinders, water proof, easy maintenance.

Both rotary blades and stationary blades are made of alloy steel, such as D2, good durability, and blade sharpening for reusing is available in a long time once they are blunt.

2, driving system

The drive motor is mounted on tension rails to allow easy adjustment of the V-belt tension. And the motor drives the rotor for grinding working through V belt and pulley.

Good quality motors are used for our film grinder machines, for example, WN, SIEMENS, SIMO and JIAMUSI, with high efficiency of energy utilization for long term stable running.

3, feeding hopper

Usually, side feeding inlet is made on the hopper for our plastic grinder machines, and plastic surtains are installed at the inlet to prevent the materials go out while the grinding crushing. On the top inside of the hopper, water spray unit is installed, but the users can choose to crush the film and bags with water or without water.

Two units are optional for opening of the hopper for blade replacement or chamber cleaning. One is mechanical screw rod design, the other one is hydraulic system.

4, screen unit

Screen sieves with different mesh sizes are replaceable to meet the required materials size after grinding. usually, the popular hole diameter is 60-100mm on the sieves for waste plastic films and bags recycling.

A mechanical unit is used for easy change working of screen sieves on the plastic grinders.

The hinged screen frame is convenient for replacement of the screen sieves, and it can be installed and removed through a separate door.

5, grinder body frame

The body frame has a solid welded construction with thick carbon steel to form the heavy structure for steady crushing grinding, it can avoid the frame cracking or damage by excessive stress while crushing grinding with full material loading. And anti vibration rubber feet can be fixed to reduce vibration and noise.

6, safety protection device

A safety limit switch is installed on the grinder frame, once the hopper or front door is not closed well, the plastic grinder will not start up. And two emergency stop buttons are set on the machine body and control panel for quick response when emergency happen.

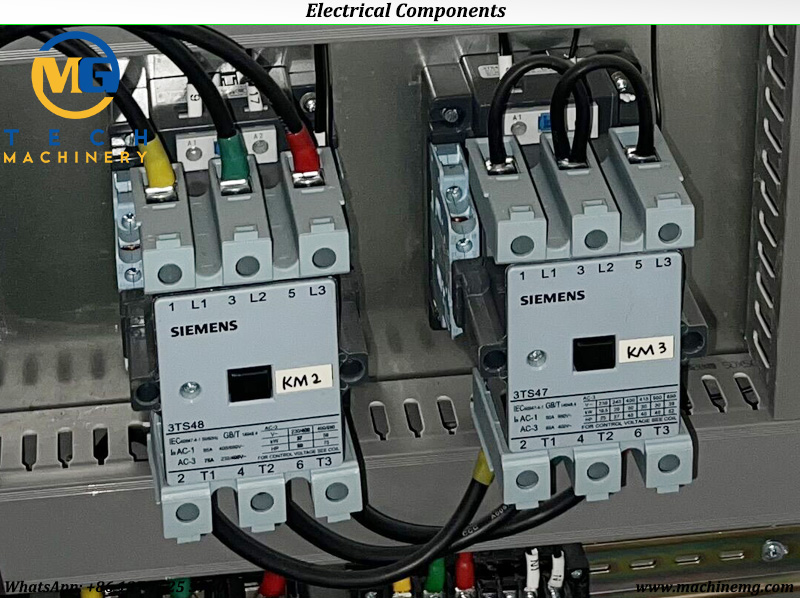

7, control cabinet

A control cabinet is used for easy control of the grinder working, high quality electrical components and parts are chosen for the cabinet, such as SIEMENS contactor, safe and reliable.

Auxiliary machines to the plastic film grinder machine:

1, belt conveyor: it's used to feed the films and bags into the grinders from ground, instead of the manual feeding, it brings steady material feeding and grinding, and more output.

2, screw loader: it's used to discharge the crushed films and bags out from the grinder bottom. Especially in a complete recycling washing line for the waste plastic films and bags, it is a key units to ensure the continuous working of the recycling line.

Is that the correct plastic grinder machine what you are looking for?

please send an enquiry now for more details and offical quotation in short time.

Advantage of the plastic film grinder machines in MG machinery company:

1, the main rotor passes strict dynamic balancing testing.

2, V shape installation for alloy blades to get higher output.

3, external bearing mounting for heavy duty bearing, water proof,dust proof, easy maintenance.

4, mechanical hydraulic system for hopper opening and sieve change, labor saving, fast and safe.

5, with safety limit switch, if the crusher parts is not closed 100%, it can‘t be started.

6, robust welded steel construction, heavy crusher model.

7, over load protective automatically.

8, quality certificate.

Etc.

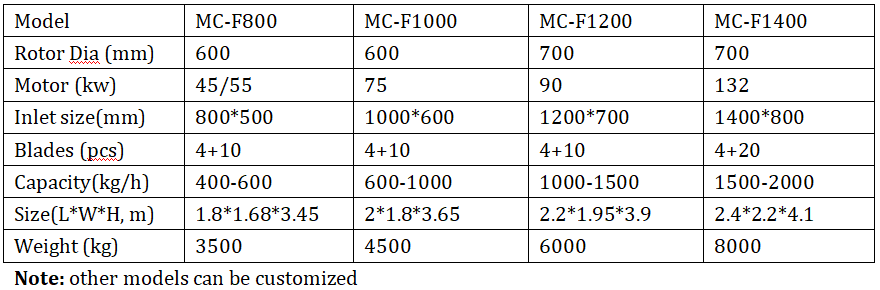

Model of waste plastic film grinder machine in MG Machinery:

Why choose us?

1, provide the right shredder models and proposals according to your requirement quickly.

2, professional designs of machine flowchart and workshop layout quickly

3, best quotation for same level shredder machine from China.

4, high machine manufacturing technics and strict quality requirements.

5, complete machine testing to confirm the high performance parameter before shipment.

6, shipment on time. And we can help on ship booking, container loading with good fastening in factory

7, dispatch engineer for after sale service in your company on time

8, training for machine and operation.

9, technology support all lifetime.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007, for example, Japan, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Georgia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.