The PET Bottle Crusher Machine is an advanced industrial equipment designed to compress and grind empty PET bottles, converting

bulky waste PET bottles into manageable, space-saving materials. Ideal for plastic recycling plants, waste plastic recycling station, and

PET bottles production factories, etc. This plastic crushing machine streamlines waste processing while promoting sustainability.

Our Heavy duty PET bottle crusher machine can process kinds of waste PET bottles, including but not limited to the following discarded

PET plastic bottles:

1, Beverage Bottles:

The most common type of PET bottles, used for mineral water, carbonated drinks, juice, tea beverages, etc.

2, Cooking Oil Bottles:

PET bottles used for cooking oil, typically with higher heat resistance and strength.

3, Cosmetic Bottles:

Used for shampoo, body wash, skincare products, etc., often featuring elegant designs and various colors.

4, Pharmaceutical Bottles:

Used for medicines or health supplements, requiring higher hygiene standards.

5, Detergent Bottles:

Used for detergents, disinfectants, and other cleaning products, usually with chemical resistance.

Composition of PET bottle crusher machine

1, Alloy Blades: Precision-engineered rotating blades made from hardened alloy steel, capable of cutting kinds of PET bottles.

2, Strong Rotor: precision processing, and passed a rigorous dynamic balance test. V-shape blade mounting for fixing the rotary blades.

3, Powerful Motor: Equipped with an energy-efficient electric motor to ensure continuous high-torque operation.

4, Feeding Hopper: A large-capacity input chute designed to accept bulk materials, reducing manual handling and speeding up processing.

5, Heavy Frame: the crusher frame is made of fine carbon steel, to reduce the vibration while crushing, and ensure the steady crushing in

long lifetime.

6, hydraulic mechanism (optional): for this heavy duty plastic crushing machines, hydraulic mechanism is usually equipped for opening

the top cover to replace the blunt blades and other maintenance, as well as screen sieves.

7, Control Panel: User-friendly interface for on-off and safety controls, with emergency stop function.

8, Feed Unit (optional): usually belt conveyors are the most cost-effective machine for feeding the waste PET bottles into the plastic

crushing machines.

9, Discharge Unit (optional): Integrated conveyor belt or collection bin for easy transport of crushed plastic films.

Primary Applications of the PET bottle crusher machine

1, Recycling Plants: Optimize plastic processing for resale or reuse.

2, Beverage Manufacturers: Recycle PET bottles from production lines.

3, Eco-Conscious Businesses: Align with corporate sustainability goals.

4, Supermarkets and Restaurants: Manage plastic waste from bottled drinks.

In MG machinery company, our Plastic PET Bottle Crusher Machine stands out for its superior performance and practicality, making it an ideal choice for plastic recycling and waste management.

1, Powerful Motor and Advanced Crushing Mechanism: The machine is equipped with a high-performance motor that delivers ample power to drive the advanced crushing mechanism, achieve a high throughput and reducing processing time.

2, Precision Cutting Technology: Featuring advanced cutting technology, our PET Bottle Crusher Machine provides precise control over the size of the crushed plastic particles. This is particularly important for recycling operations that require specific particle sizes for further processing or resale.

3, Durability and Reliability: Constructed from high-quality materials, our crusher machines are built to withstand the rigors of daily use. Its durable components and reliable performance ensure long-term operation with minimal downtime, maximizing productivity and reducing maintenance costs.

4, Easy Operation and Maintenance: Designed with user-friendliness in mind, our Plastic Crusher Machine is easy to operate and maintain. The modular design facilitates easy access for routine maintenance and repairs. And hydraulic mechanism is used to help the blade replacement working. Safety limit switch is installed ensure the safe maintenance.

5, Cost-Effective Solution: its durable construction and reliable performance reduce the need for frequent repairs or replacements, further lowering operational costs.

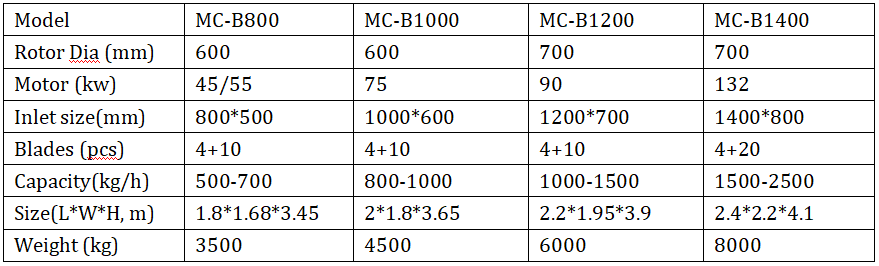

Model of PET bottle crusher machine in MG Machinery

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.