This Vertical Hydraulic Cutting Machine is a core pre-processing unit in modern resource recovery and waste management systems. It is

specifically designed to break down and reduce bulky, voluminous, and monolithic waste materials. Utilizing immense hydraulic shear

force, it efficiently cuts large waste items into uniform, smaller pieces, providing a vital foundation for subsequent processes such as

shredding, transportation, sorting and recycling.

Core Working Principle

The equipment employs proven hydraulic transmission technology. An electric motor drives a high-pressure hydraulic power unit,

generating tremendous force. This force actuates the vertically installed main hydraulic cylinder, which drives a heavy-duty cutting blade

in a straight-line, downward motion. This "vertical guillotine" action, combined with a fixed base anvil, cleanly shears entire loads of loose

waste with immense force, often amounting to hundreds of tons.

Primary Application Fields

1, waste plastic recycling industry: plastic lumps, drums, pallets, pipes, films, jumbo bags, etc.

2, Bulky Waste Processing Centers: For breaking down discarded furniture, mattresses, sofas, etc.

3, rubber recycling plants: rubber belts, strips, tires, blocks, silicone waste, etc

4, paper and carton recycling: kinds of waste books, carton boxes, paper, etc.

The Vertical Hydraulic Cutting Machine acts as the "pathbreaker" in the waste volume reduction and resource recovery process. With its

unparalleled powerful cutting force, broad material adaptability, and highly efficient and stable performance, it effectively solves the

industry's pain points of "difficult handling, difficult transportation, and difficult shredding" associated with bulky waste. It is a key piece

of equipment for building a modern, efficient recycling system.

Outstanding Performance and Advantages

1.Exceptional Size Reduction Capability & Wide Applicability.

The powerful hydraulic system easily handles large, bulky, and loose materials that are challenging for conventional equipment, such as discarded sofas, mattresses, baled waste paper, plastic piles, pallets, lumps, drums, plastic film bales, jumbo bags, rubber blocks, old furniture, and industrial scrap, achieving "versatility in one machine."

2.Significant Volume Reduction & Enhanced System Efficiency.

Cutting and compressing large, loose waste into compact blocks drastically reduces material volume. This not only saves storage and transportation space but also significantly improves the efficiency and throughput of downstream shredders or crushers.

3.Robust Structure & Stable, Reliable Operation.

The box-type structure, welded from high-strength steel plates, ensures the frame remains rigid under enormous shear forces. The vertical design provides stable material centering during cutting, resulting in a smooth process with minimal shock and excellent equipment durability.

4.Safe Operation & Easy Maintenance.

It comes standard with safety features like two-hand control buttons and safety guards, ensuring operator protection. The rational structural design allows for easy access and maintenance of key components.

5.Automation Integration & Reduced Labor Intensity.

It can be equipped with automatic feeding conveyors, pusher devices, and PLC control systems for continuous, automated operation, freeing workers from heavy and hazardous manual dismantling tasks.

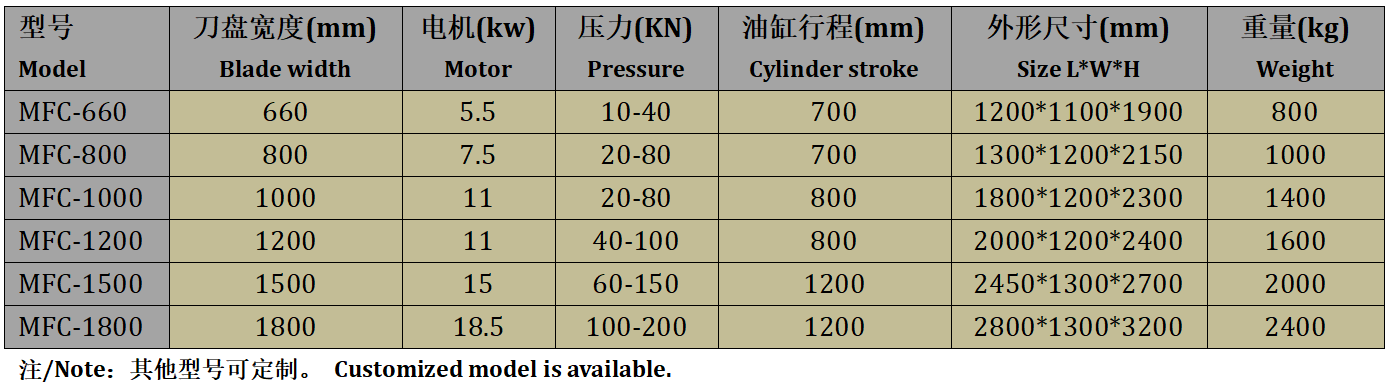

From MG machinery company, you can have different choice of the vertical hydraulic cutting machines:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.