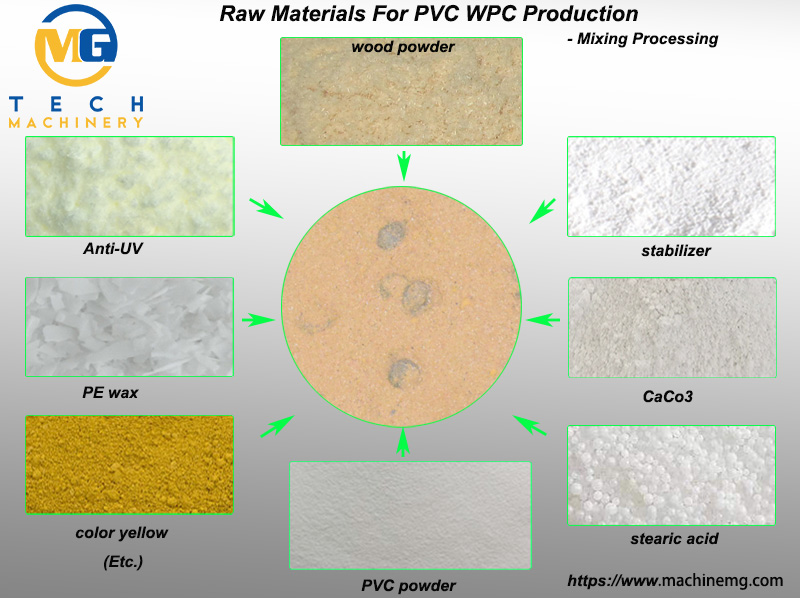

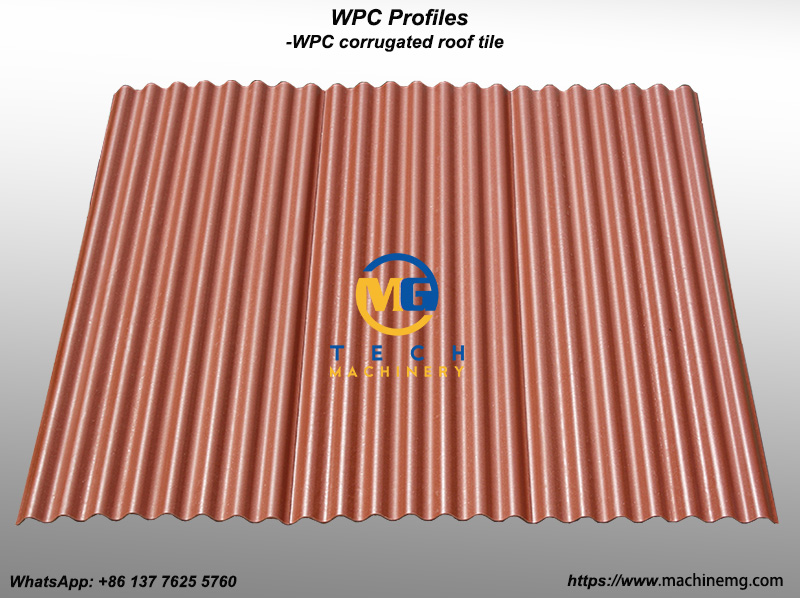

WPC roof tile production line is used to produce the corrugated wpc roof tiles from wood powder, PE or PVC plastic and processing additives. By equiped with different WPC tile molds, the WPC roof tile production lines are suitable for extrusion of 300~1000mm wpc tiles.

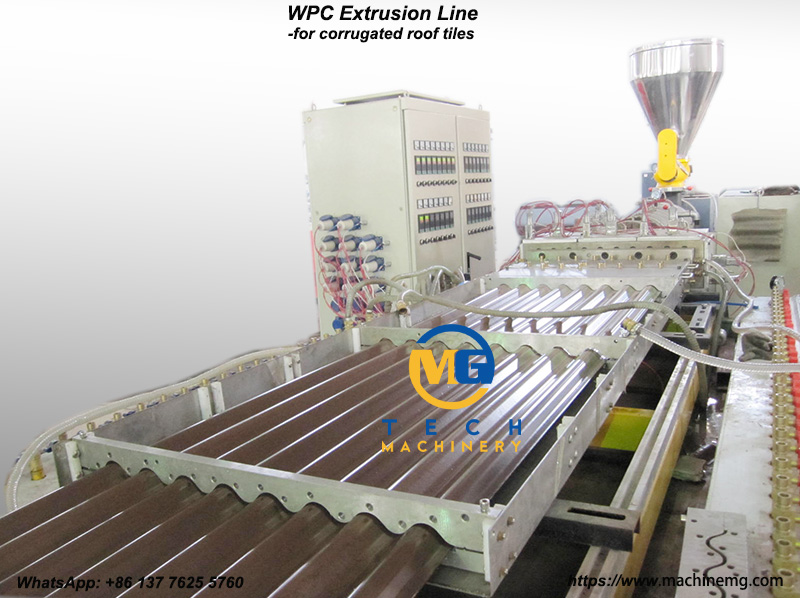

Usually, the WPC roof tile production line includes the following units:

1, WPC extruder

2, calibration table

3, nip roller hauling machine

4, transverse cutter

5, roller stacker

Meanwhile, some auxiliary machines are necessary in a WPC roof tile plant, for example, the WPC materials mixer and wpc compounding pelletizer, etc.

WPC extruder:

It's the conical double screw type, the barrel and screw is made of alloy 38CrMoAlA. Cast aluminum heaters with air coolers are used, and the OMRON or RKC temperature meters are installed for automatic temperature control.

A horizontal screw feeder is for metering feeding the materials from the hopper into the barrel.

Connection could be direction type or split type for motor and reduction box.

Powerful vacuum degassing system is used to ensure the good extrusion for the wpc mixture materials.

Calibration table:

It's used for installation of the shaping molding parts and cooling tank of the wpc roof tile molds, and supply the cold water for cooling the wpc roof tiles while extrusion, and a vortex air pump will supply the strong wind for blowing off the water from the profile surface.

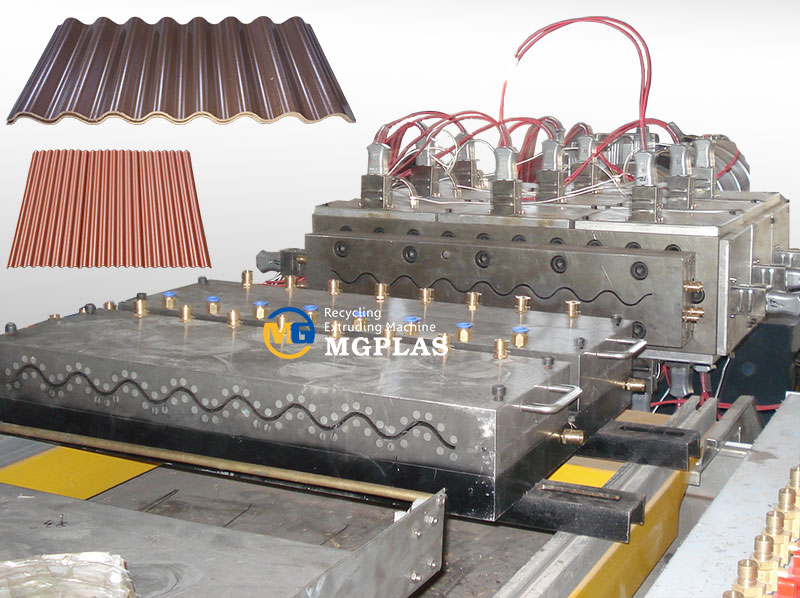

WPC roof tile molds:

The roof tile molds are manufactured according to the corrugated shape and wpc materials properties, so that the mold can be used to produce the most pratical tiles for roof building.

Alloy steel is used for the molds, and one set mold usually includes the die head, shaping zones and cooling tank.

In the cooperation, we will provide full support on the proposal of wpc roof tile machines, wpc material formula and technology for operation and maintenance.

The corrugated wpc roof tiles have full advantages of wpc profiles, for example, water proof, anti corrosion and good adaptation to weather in long lifetime, etc.

Advantages of WPC roof tile production line in MG Machinery:

1, barrel and screws of the extruder are made of alloy

2, screw structure is designed according to the wpc materials properties for good plasticizing.

3, accurany temperature control for the barrel heating and cooling.

4, extruder has good stuitability for wpc tile molds.

5, steady extrusion and shaping.

6, auto protection function while overload.

7, quality certification

etc

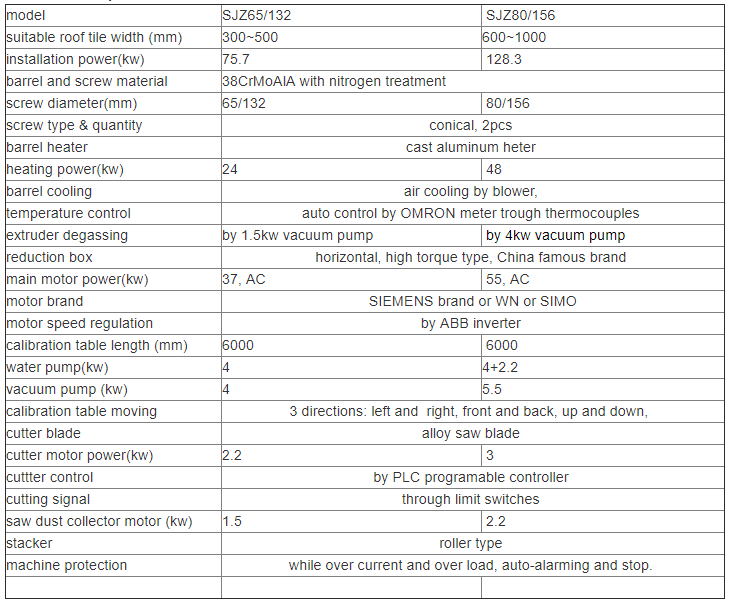

Models of WPC roof tile production line in MG Machinery:

What we can do for you to build the wpc plant for the wpc roof tiles and other wpc profiles?

1, machine proposal design.

2, workshop flowchart and layout design.

3, wpc products reference on shapes and sizes, and performance.

4, good quotation.

5, machine quality guarantee

6, delivery on time.

7, wpc material formula for production.

8, engineer service in your factory for machine installation, commissioning, operation and training.

9, lifetime service for the machines and formula technology upgrade.

etc.

6,

Our machines have be exported to many countries, for example, Japan, Thailand, Vietnam, India, Ukraine, Russia, Serbia, USA, Mexico, Chile, Peru, etc.