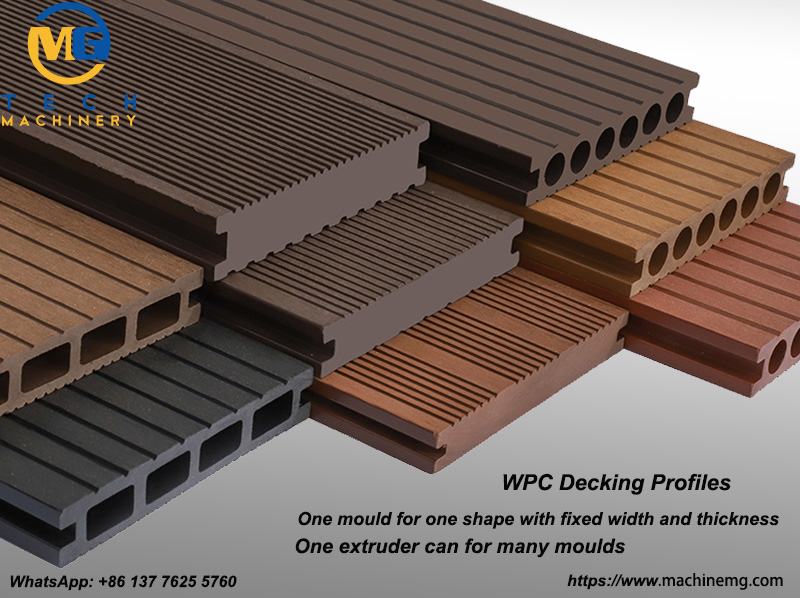

WPC profile extrusion line is used to produce the wood plastic composite profiles from plastic HDPE or PVC, wood powder or bamboo powder and processing additives. With different moulds, the wpc extrusion line can produce kinds of wpc profiles for different usage, for example, wpc decking, wpc panel, wpc fence, wpc wall cladding, wpc board, wpc door profile, wpc door frame, wpc window profile, wpc pallet profile, wpc pillar, wpc bench profile, wpc broomstick and wpc roof tile, etc.

The WPC profile extrusion line consists of a twin screw extruder, valibration table, haul-off machine(optional), cutter and stack.

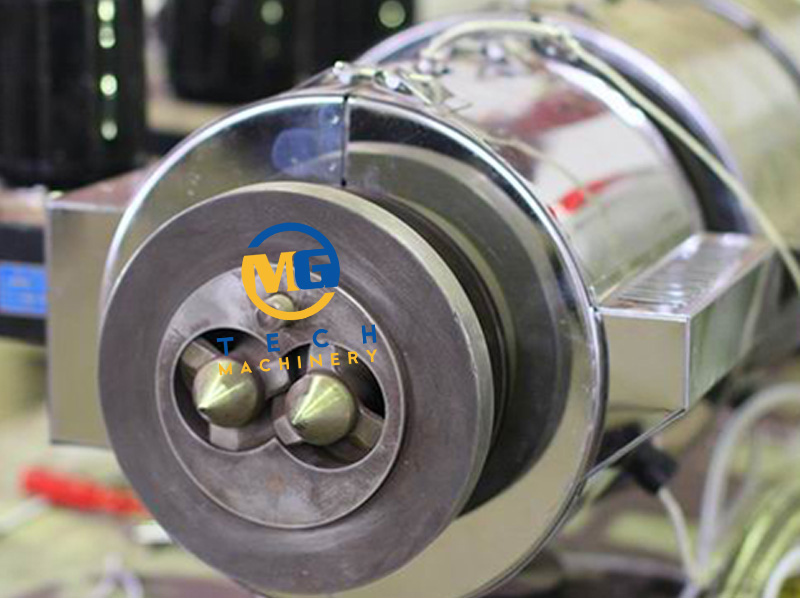

Tiwn screw extruder with powerful motor and reduce for extrusion driving, and vacuum degass system for material treatment before extruding shaping in the mould.

Barrel and screw are made of alloy steel, with nitriding processing.

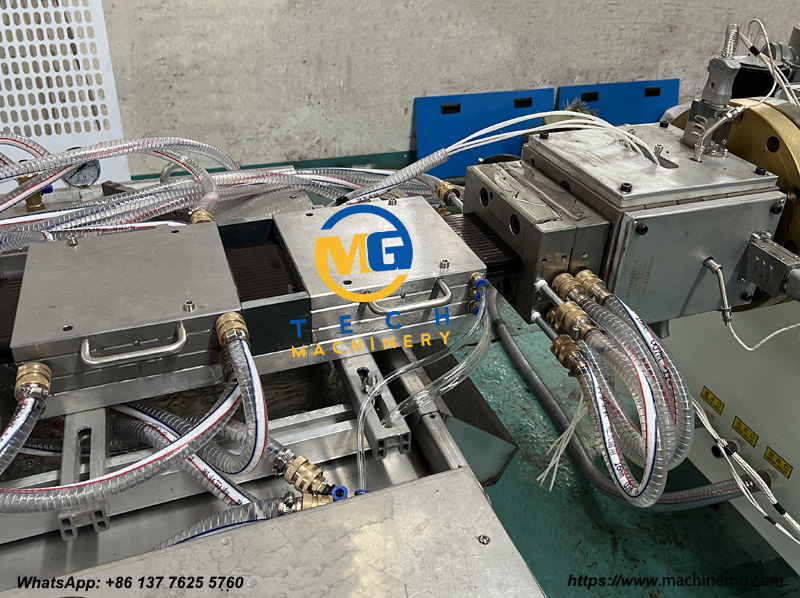

Mould is connected to the extruder head, shaping zones and cooling tank are installed on the calibratio table. water cooling is used for wpc profile shaping assistant. For the wpc decking profiles, the moulds include two shaping zones usually.

In the main control cabinet, good quality inverter and electrical parts are used, for example, ABB inverter, SIEMENS parts, etc.

temperature control meters are set on the control panel, current meter, speed of material feeder and extruder are put on the PID panel, It's very easy for operation control.

Wood plastic composite profiles are made of wood fiber (wood powder) and thermoplastic such as PE, PP or PVC. The popular wpc profiles are PE WPC and PVC WPC at present. Therefore, there are two different WPC extrusion machine as PE WPC extrusion line and PVC WPC extrusion line.

PE WPC extrusion line consists of conical twin screw extruder, calibration table, cutter and stacker.

PVC WPC extrusion line consists of conical twin screw extruder or single screw extruder, calibration table, haul-off, cutter and stacker.

WPC extrusion moulds are changeable units on the wpc profile extrusion lines by different size and shape requirements of wpc profiles.

Other auxiliary machines are optional units by the different plastic choice in the wpc materials, For example, wpc mixer, wpc granulating machine, wpc sanding machine and wpc embossing machine, etc.

Advantage of WPC profile extrusion line in MG Machinery:

1, lower power consumption.

2, uniform and high plasticizing ability.

3, stable and smooth extrusion.

4, good profile shaping.

5, higher automation.

6, strong structure.

7, auto protection function while overload.

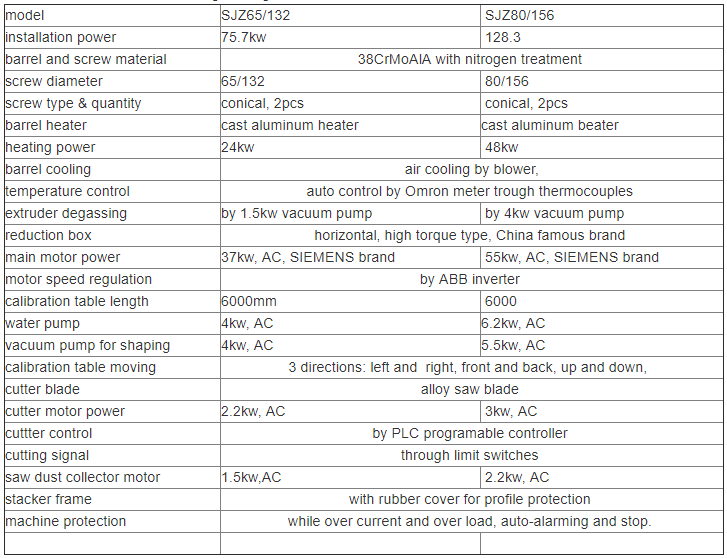

Models of WPC profile extrusion line for your choice:

What we can do for you in the cooperation:

1, Professional machine proposal according to your requests on shapes, sizes and capacity monthly or yearly.

2, reasonable workshop flowchart and layout design according to your factory size provided.

3, machine and molds testing well before shipment.

4, machine delivery on time.

6, engineer service is availabel in your wpc factory.

7, material formula tranfer freely.

8, free technology upgrade on parameter adjust and better formula details sharing.

9, cost price for machine parts out the guarantee time.

etc.

Our machines have been exported to Japan, Vietnam, Thailand, India, Ukraine, Russia, Serbia, etc.