WPC decking production line is used to produce the new construction decking profiles from wood powder, PE or PVC plastic and processing additives. Besides the wood powder, bamboo, peanut hulls, straw, cotton stem and unused woodworking materials like barks can be used for wpc production.

Due to the good performance of water-proof, anti-corrosion and anti-slip, the WPC decking profiles are widely used for footpath in parks and scenic area, piers of lakes and rivers, etc.

As usual, one WPC decking production line consists of conical double screw extruder, calibration table, haul-off, cutter and stacker, as well as some auxiliary machines.

By equipment with different moulds, the WPC decking production line can be also used to produce other wpc profiles, for example, wpc wall cladding, wpc fence and wpc pillar, etc.

At present, HDPE, PP and PVC are the popular plastic materials for WPC production. 100% recycled HDPE or PP can be used by the wpc formula technology in MG Machinery.

To prepare the good proposal for you, please list the plastic type in your enquiry, which will you use for WPC process, We will provide our professional guidance in the proposal.

Advantages of WPC decking production line in MG Machinery:

1, uniform and high plasticizing ability.

2, steady and smooth extrusion.

3, good profile shaping.

4, higher automation.

5, lower power consumption.

6, auto protection function while overload.

7, strong structure.

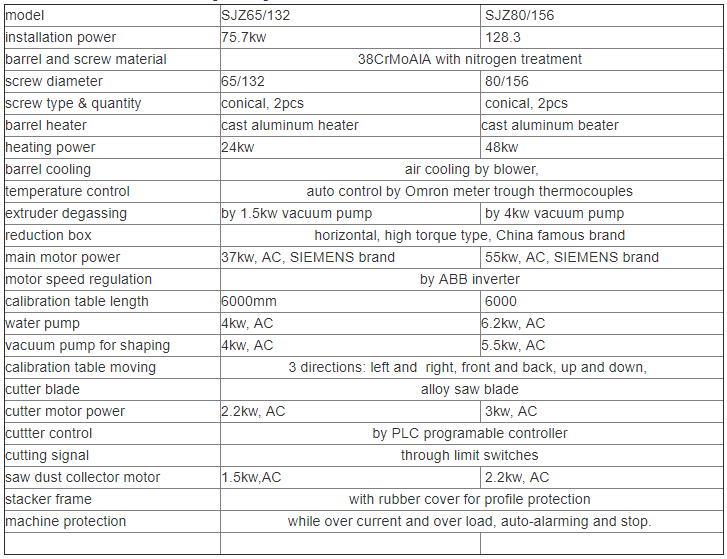

Models of WPC decking production line in MG Machinery:

Why choose us?