WPC extrusion line, with new process of co extrusion in 2024, is mainly used to produce the hollow or solid wood plastic composite profiles with two or three kinds of WPC material mixture from wood powder, HDPE plastic and processing additives. By the WPC and WPC co extrusion technology, the WPC plants can use cheap WPC materials for inner layer extrusion of WPC profiles, and high quality WPC mixture mateiral for extruding the outer layer of WPC profiles, but the required material quantity is less for outer layer of WPC.

Based on this WPC WPC co extrusion process, the WPC extrusion line can bring the following properties for the WPC plants:

1, save material cost for WPC profile extrusion.

2, improve the WPC quality with less cost, such as better weather resistance.

3, incease the skin affinity of WPC profiles especially for the deckings, benches and pergola project, etc.

With different WPC molds to work on the WPC extrusion line, kinds of WPC products can be produced with the WPC WPC co extrusion technology, for example, wpc decking, wpc panel, wpc fence, wpc wall cladding, wpc pergola profile, wpc board, wpc pallet profile, wpc pillar, wpc bench,etc.

The WPC extrusion line includes the following unit for WPC and WPC co extrusion:

1, material loader,

2, conical twin screw extruder: SJZ65 or SJZ80,

3, co extruder: single screw extruder or twin screw extruder can be chosen for WPC WPC co extrusion.

4, wpc mold,

5, calibration table,

6, cutter

7, stacker.

8, control cabinet

Auxiliary machines and units in the WPC plants

1, Sanding machine, brushing machine, on line embossing machine and off line embossing machine, etc.

2, WPC mixer and WPC compounding pelletizers machine are auxliary machines for the wpc profile extrusion,

3, WPC crusher and pulverizer for waste wood plastic recycling.

4, Air compressor and water chiller can be also ordered together with WPC co extrusion lines.

5, Wood powder making machine and waste plastic recycling washing machine and pelletizer machine are chosen for use to save

part of material cost if the WPC plants have enough scale.

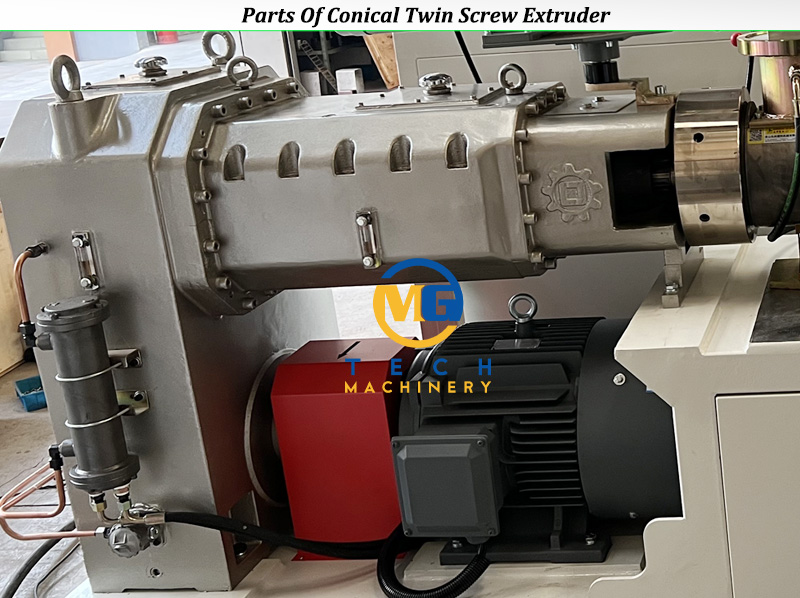

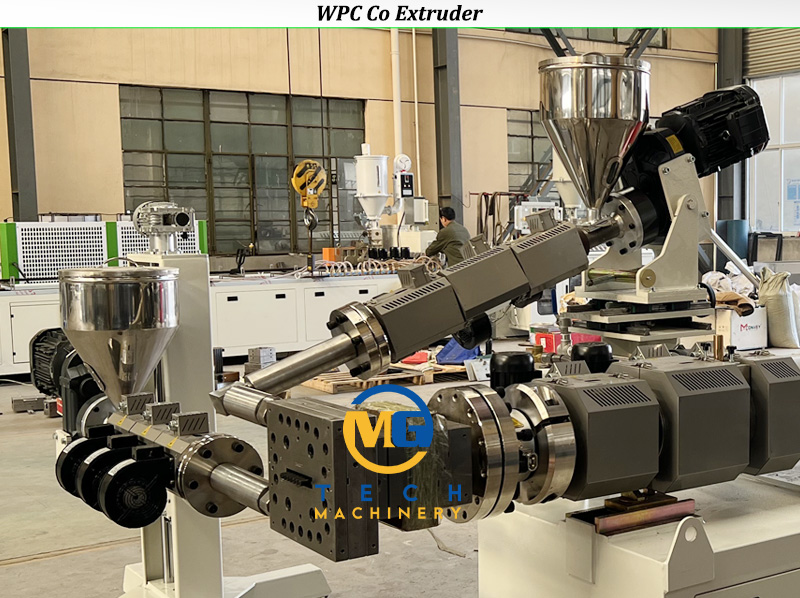

Main extruder:

Twin screw extruder is usually used for the inner layer material extrusion of WPC and WPC co extrusion profiles.

Alloy 38CrMoAlA barrel and screw are assembled on our WPC extruders, with powerful motor and reducer for driving.

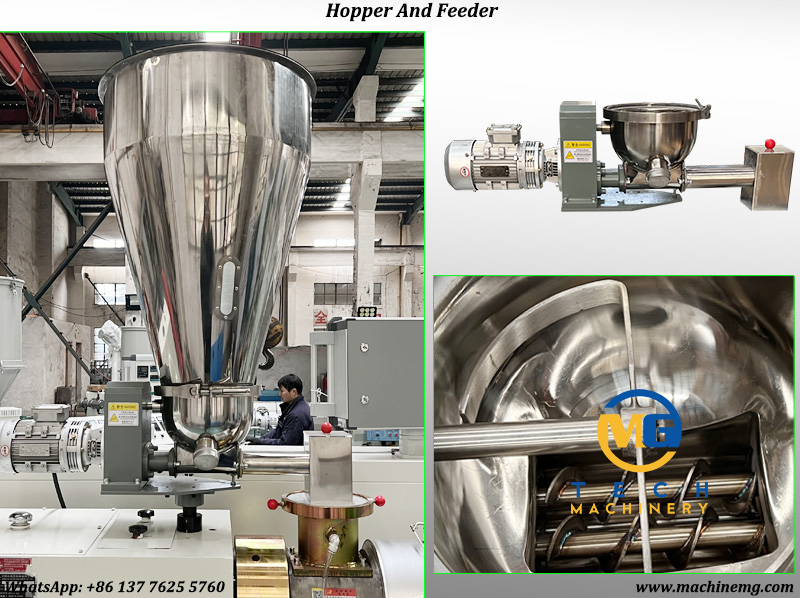

metering feeder, cast aluminum heater and good vacuum degassing unit.

Main extruder is a very important unit of the WPC extrusion lines for WPC co extrusion production.

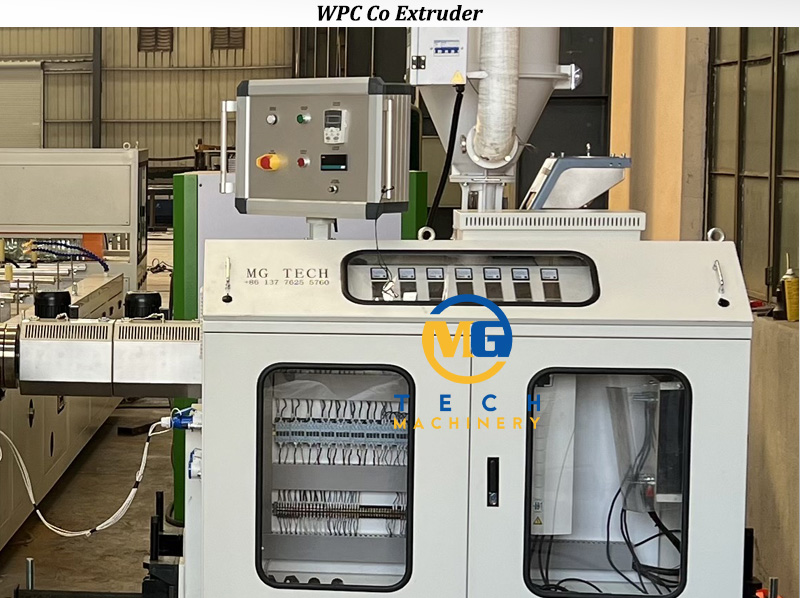

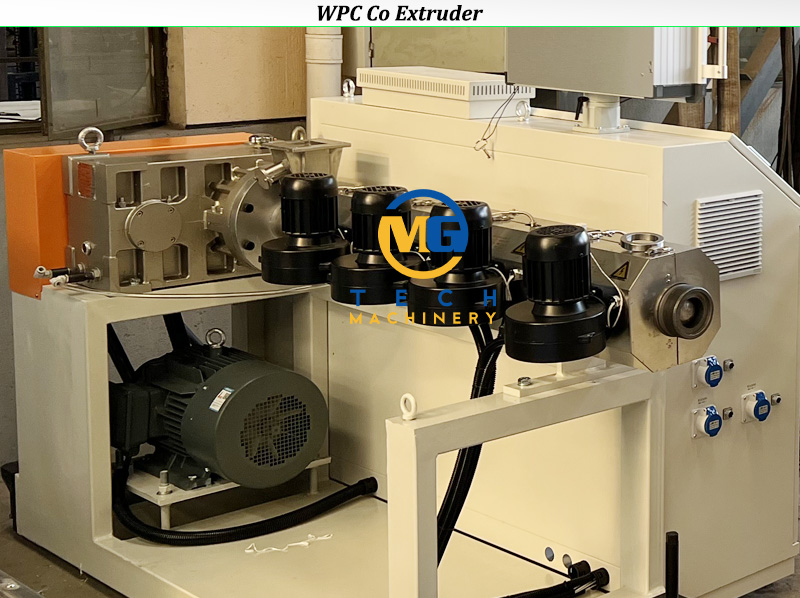

Co extruders

Co extruder is used for extruding the outer layer of WPC and WPC co extrusion profiles, according to different materials formula

and co extrusion thickness, single screw extruder or twin screw extruder can be chosen for this WPC extrusion line for co extrusion.

Alloy steel is used for the barrel and screw, vertical reducer, AC motor, cast aluminum heaters and air cooling for co extruder.

As usual, hopper dryer is required on the co extruder for WPC co extrusion production.

If out layer of the co extrusion WPC are separated into two parts, each part requires one different color, then two co extruders are required for the WPC co extrusion produciton.

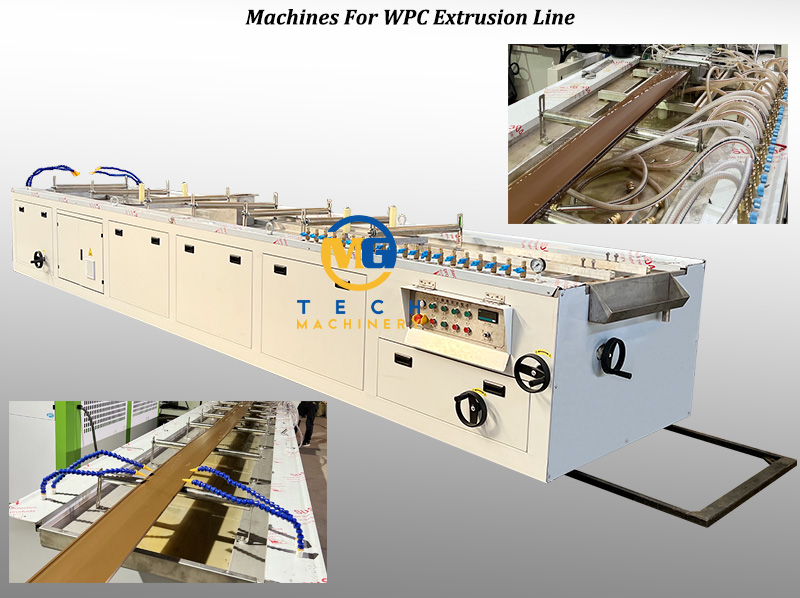

Calibration table

Calibration table includes the auto water circular system for cooling wpc profiles, and vortex air dryer for blow off the left

water after cooling. It can be adjusted on 6 directions for easy installation and operation of the wpc moulds while production,

control panel with waterproof cover, electrical cabinet is hiden in the frame structure, uniform door plates for beatiful apparence.

Cutter machine

The cutter machine is used to cut the WPC profiles into short piece while the production. While cutting, the WPC profile compressing

by pneumatical machanism, automatic length fixed for cutting through the PLC module and touch screen for parameter set.

According to different width of WPC profiles for cutting, the WPC plants may require vertical cutter or transverse cutter for good

cutting result.

Control Cabinet

Inverter, temperature meter and electrical components are from famous brands for the main control cabinet, for example, ABB inverter,

OMRON temperateure meter, etc. material feeding speed and extrusion speed can be adjusted easily on the panel.

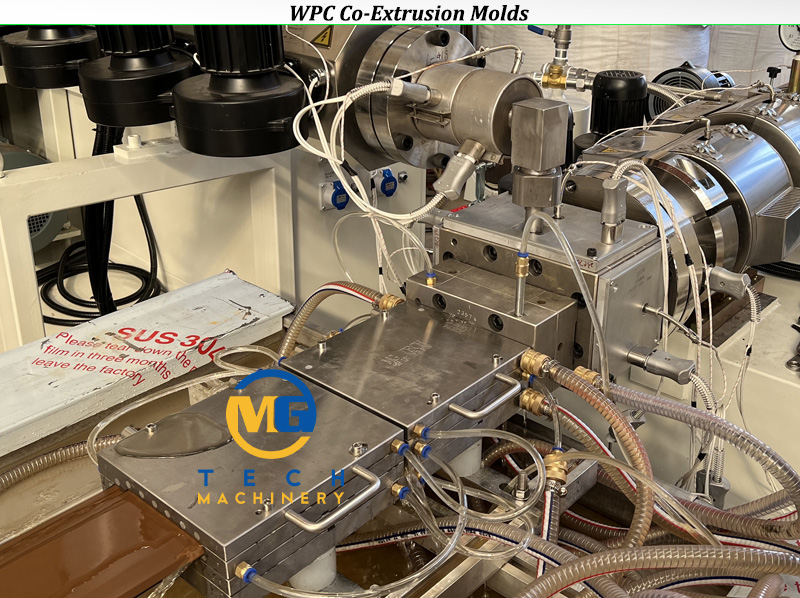

WPC molds for WPC and WPC co extrusion process

By different requirements of co extrusion on different WPC products, there are different designs on WPC and WPC co extrusion

moulds, to ensure the best shaping and production for the WPC co extrusion profiles.

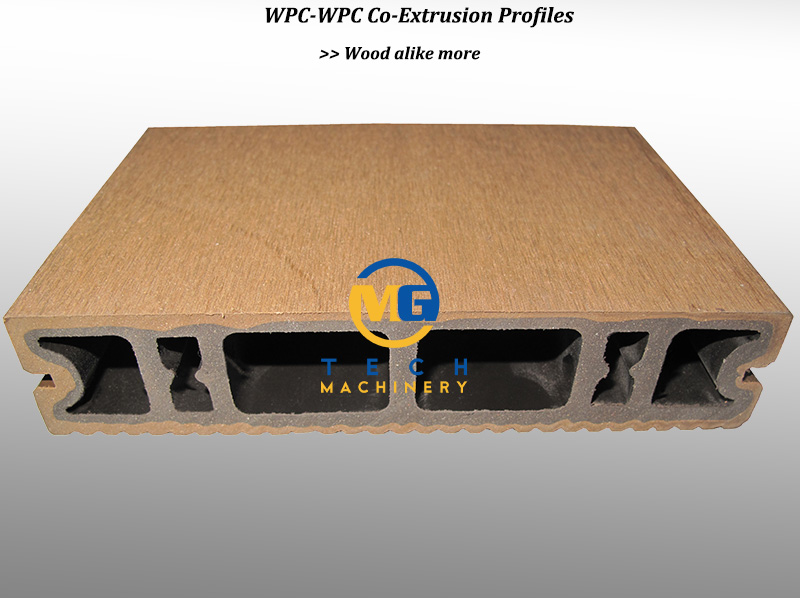

What do the WPC and WPC co extrusion products look like?

For WPC co extrusion products, we can provide the WPC machines for three co extrusion WPC profiles at present:

WPC ASA co extrusion, WPC PE co extrusion and WPC and WPC co extrusion.

Usually, there is still some plastic trace on the products from WPC ASA and WPC PE co extrusion even finish the after processing

on the WPC surface, but WPC and WPC co extrusion profiles bring a different surface which is more wooden alike.

Advantages of WPC extrusion line for WPC co extrusion process in MG Machinery:

1, stable and smooth extrusion.

2, uniform and high plasticizing ability.

3, good profile shaping, less waste products

4, auto protection function while overload.

5, higher automation.

6, lower power consumption.

7, quality electical applicance for control cabinet: ABB inverter, SIEMENS contact, OMRON meters, etc.

8, dust-proof visual cover plate for contaol cabinet.

9, strong structure.

10, long lifetime.

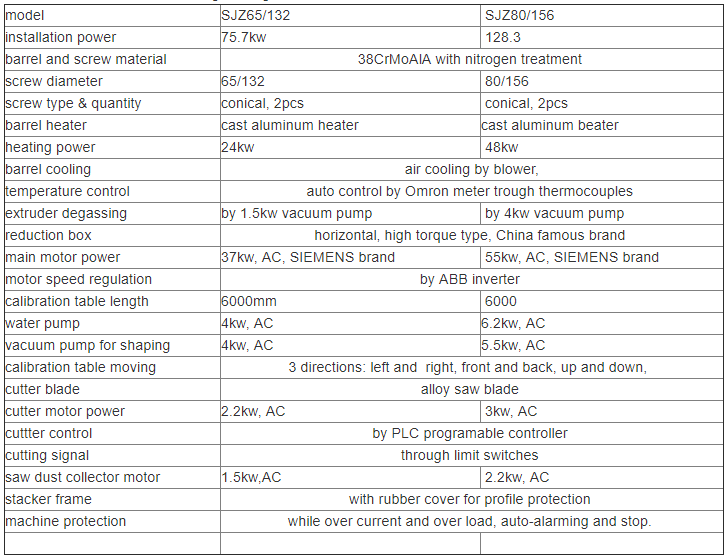

Models of WPC extrusion line for co extrusion WPC in MG Machinery:

Why choose us?

1, we can provide the most suitable solution proposals according to your materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation on time.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007,

for example, Japan, Indonesia, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia,

Geogia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.