The twin shaft shredder machine is used for disposing kinds of soft plastic waste such as plastic films and bags, to get smaller material pieces by shearing, tearing and squeezing while the shredding process. It's an efficient industrial shredder for recycling soft waste plastic materials on coarse crushing step.

Application of Twin shaft shredders for soft plastic waste

1, kinds of waste plastic films: package films, package bags, agricultural films, greenhouse films, tobacco mulching films, garbage film, etc.

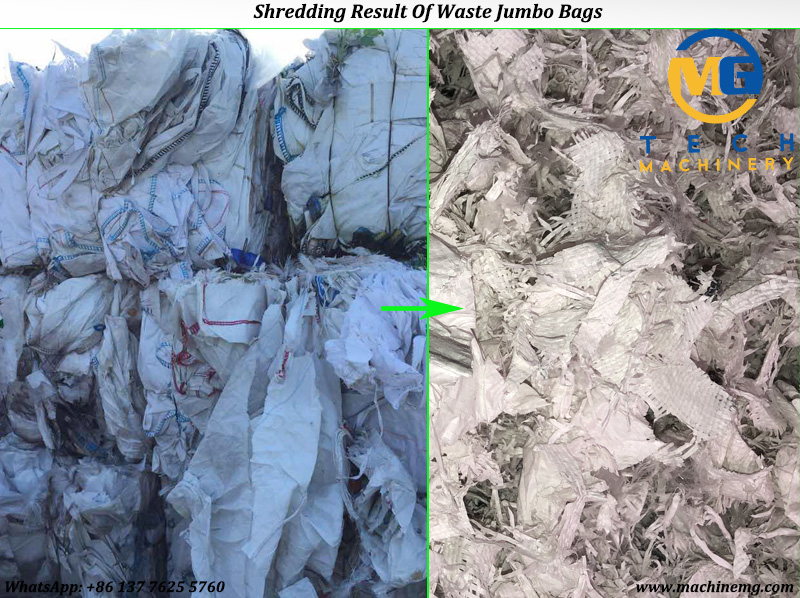

2, kinds of PP plastic bags: jumbo bags, woven bags, sack bags and non woven fabric wastes, etc.

3, irrigation tapes and plastic hose.

Reference Video of twin shaft shredder for soft plastic waste on our YouTube Channel

1, twin shaft shredder for plastic films

2, twin shaft shredde for waste irrigation tapes

Consists of a twin shaft shredder machine for soft plastic waste:

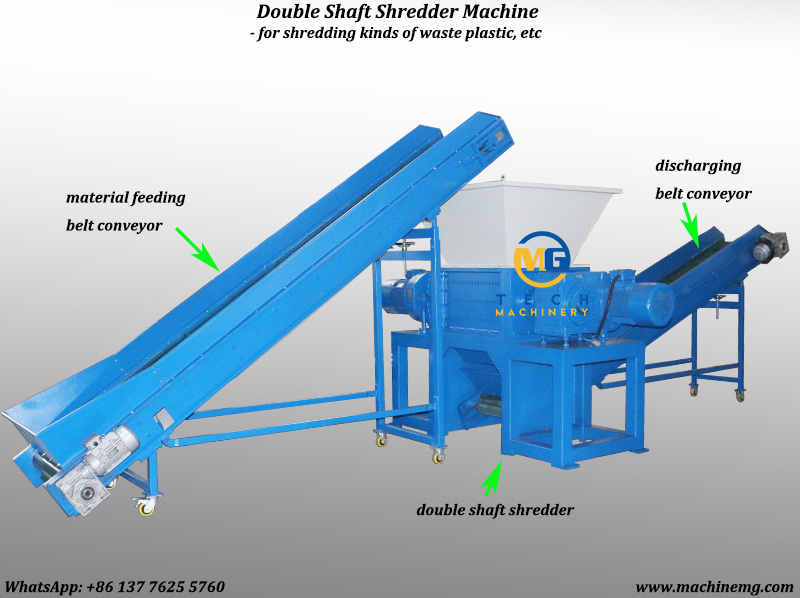

1, Feeding hopper: As the inlet for feeding the soft plastic into the shredding chamber. A hydraulic system is an optional unit for pressing the soft plastic materials to get higher shredding efficiency. And the feeding hopper of the twin shaft shredder is made as flared shape for easy feeding, especially for the large quantity soft materials.

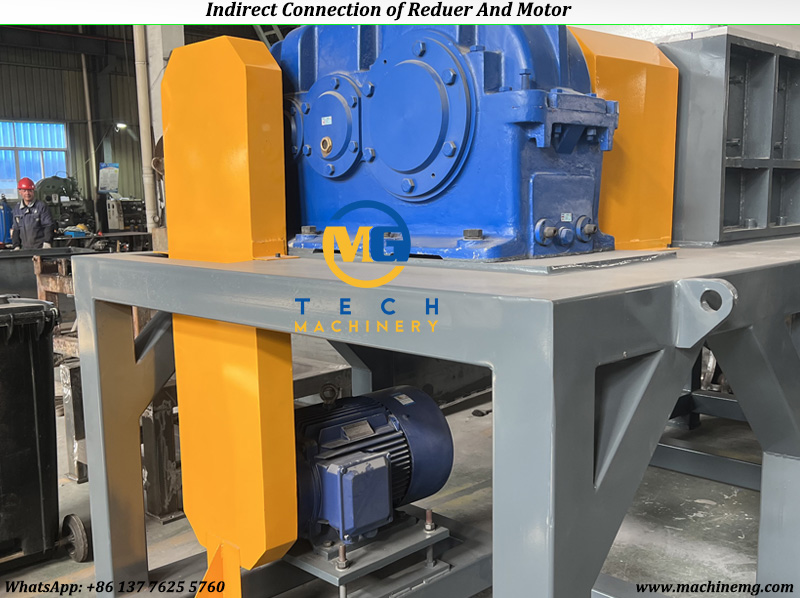

2, Driving System: powerful motor and reducer are chosen for the shredders, famous brands products with high quality in China, or other famous brands according to your requests, for example, SIEMENS, ABB, etc.

For shredding the soft waste plastic, the planetary reducers are usually better on the big torque, more steability and higher efficiency for the tough soft mateials

There are two connection ways between motors and reducers of the twin shaft shredder. One is direct connection, the other one is indirect connection through belts and pulleys.

3, Cutting shredding chamber: two shafts with stationary and rotary blades are installed, thick steel boards are used for making the chamber walls of shredders. Different claw blades are optional according to the material conditions and size requirement after shredding, for example, 1 claw, 2 claws, 3 claws, 5 claws, 9 claws, etc.

4, feeding and Discharging units: As usual, the users can choose to connect the belt conveyors for feeding the waste plastic, and conveying the shredded plastic materials out from the shredder bottom, or let the materials drop to ground directly. Belt conveyor is a better choice on saving labor and automatic working for a whole plastic recycling line.

Screw loader can be also used for discharging the mateirals.

5, Machine frame: use thick carbon steel tubes and boards for making the strong machine frame, with anti rust treatment. High strength bolts are used for connection chamber body.

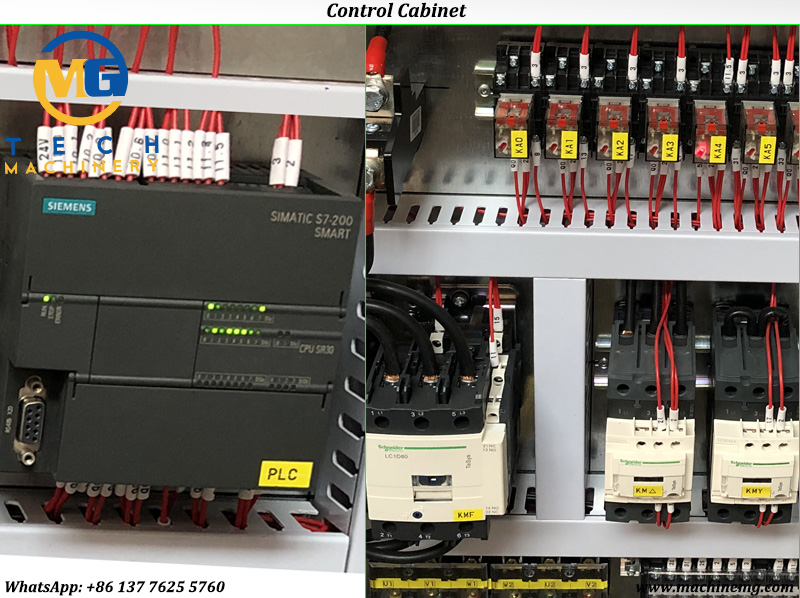

6, control cabinet: control the working of the twin shaft shredder, easy operation. Famous brands electric components and parts are installed, for example, SIEMENS or SCHNEIDER contactor, SIEMENS PLC module, etc. On the control panel, each motor is with on off button for start and stop control. One button start function can be set.

Advantages of MG's twin shaft shredders for soft plastic wate recycling:

1, powerful driving system with good quality motors and reducers. For this type of double shaft shredders, the planetary reducers are used for higher efficiency, greater stability, higher torque and larger radial loads, etc.

2, strong two shafts, alloy steel for blades with more hardness, durability, long lifetime

3, specialized design on blades claws, for grabbing and shredding different waste plastics efficiently.

4, heavy strong structure for the shredder, the frame is made of thick steel boards and tube.

5, PLC module for controlling the start, stop, reversion and overload automatic reversion.

6, Easy for removal and replacement of the blades.

7, wide usage for kinds of soft plastic waste.

8, quality certificate.

Etc.

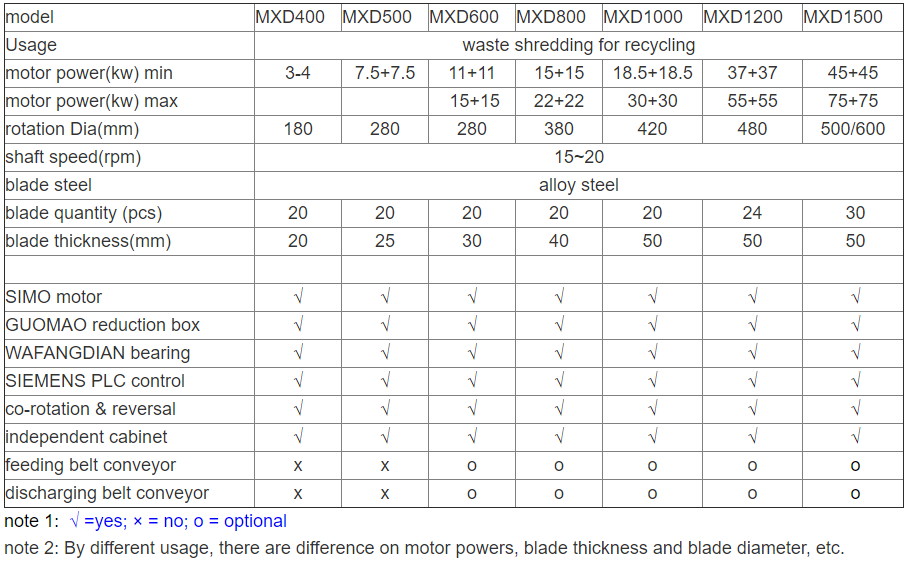

Models of twin shaft shredder for soft plastic waste:

Why choose us?

1, provide the right shredder models and proposals according to your requirement quickly.

2, professional designs of machine flowchart and workshop layout quickly

3, best quotation for same level shredder machine from China.

4, high machine manufacturing technics and strict quality requirements.

5, complete machine testing to confirm the high performance parameter before shipment.

6, shipment on time. And we can help on ship booking, container loading with good fastening in factory

7, dispatch engineer for after sale service in your company on time

8, training for machine and operation.

9, technology support all lifetime.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007, for example, Japan, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Georgia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.