Plastic bumper shredder machine is one kind of twin shaft shredder, It's mainly used for disposing kinds of waste plastic bumpers from cars, trucks and motobikes, etc.

This twin shaft shredder machine is manufactured with advanced European technology, strong structure, high working efficiency, long lifetime, lower price.

With the twin shaft design, the bumper shredder is very efficient for shredding the waste plastic bumps and shells by shearing,tearing and squeezing process. It provides a good solution for recycling the waste plastic bumpers.

By different driven system and blades design, the twin shaft shredder can used to process other waste materials as following:

1, for plastic waste materials: plastic films, plastic bags, plastic sheets, plastic boards, plastic buckets, plastic barrels, big plastic dustbins, plastic bottles, plastic chairs, plastic shells, plastic pallets, plastic baskets, etc.

2, for paper waste materials: books, newspaper, cartons, corrugated papers, etc.

3, metal waste materials: cans, oil barrel, steel sheet, steel strips, etc

4, wooden materials: wood panels, furniture board, wood pallets, plywood materials, etc.

By different conditions of different materials, the different blades designs can be choose for higher efficiency, for example, 1-claw blade, 2-claw blade, 3-claw blade and 5-claw blade, etc.

Plastic bumper shredder machine has the following characters in MG Machinery:

1, micro PLC for auto control of start and stop, co-rotation and reversal rotation of rotors while overload.

2, each rotor is driven by independent motor and gear reducer, big torque, steady working.

3, low rotation speed, low noise.

4, strong machine structure for steady running.

5, alloy steel blades, firm enough for long lifetime.

6, single claw or multiple claw blades are optional according to different materials for high efficiency.

7, kinds of rotary blade thickness are optional: 15mm, 20mm, 30mm, 40mm, 50mm and 60mm, etc.

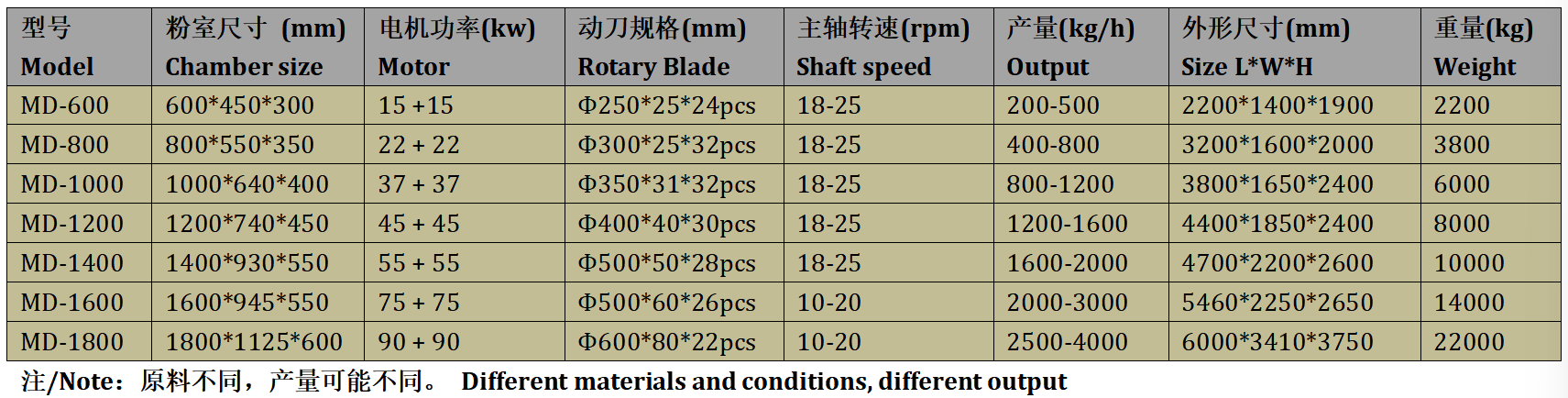

Models of plastic bumper shredder in MG Machinery:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.