The cost effective Small Twin Shaft Shredder is engineered as an efficient waste recycling machine for size reduction of household waste

materials or industrial waste. This twin shaft shredder is your ultimate solid waste management solution, designed to process a vast array

of materials with unmatched efficiency.

The small twin shaft shredder takes up less space, cost less but has wide application.

Its primary role is effective volume reduction and material liberation for downstream sorting and recycling processes.

Primary Applications

This versatile twin shaft shredder is perfect for recycling kinds of waste materials:

1, Plastic Shredding: films, bags, shells, sheets and circuit boards.

2,Metal Shredding: Light ferrous and non-ferrous scrap, metal shavings, aluminum cans, and electronic waste (WEEE).

3, paper waste: books, newspaper, cartons, etc.

4, wood waste: wood panels, MDF boards, WPC panels, etc.

For big and tough waste materials, please choose the heavy duty dual shaft shredders for use.

Searching for a cost-effective, reliable, and powerful shredding machine? This compact twin shaft shredder is the answer. Contact us for a

free quote and machine demonstration today!

Key Features & Technical Advantages:

1, Low-speed, high-torque, low energy consumption.

2, Durable alloy cutting blades, long service life and lower maintenance cost.

3, Robust dual-shaft mechanism, powerful shearing and tearing action for efficient shredder.

3, Automated PLC control, stable and safe operation.

etc

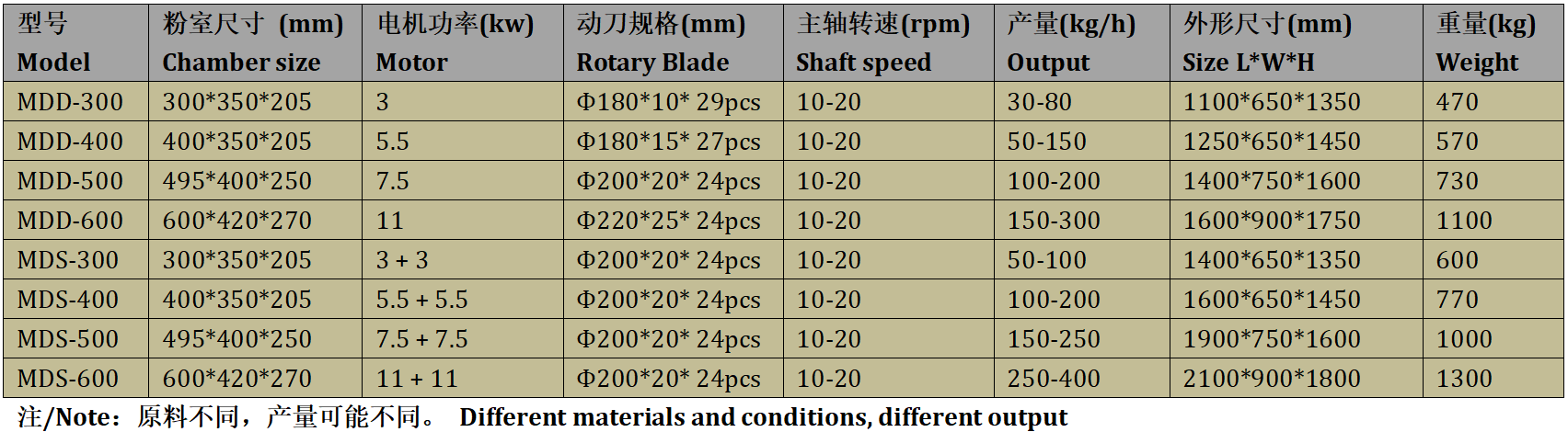

Models of small twin shaft shredder in MG Machinery:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.