Twin Shaft Shredder is a powerful, slow-speed, high-torque machine engineered for the primary and secondary size reduction of a wide

spectrum of challenging materials. Built for reliability and efficiency in demanding industrial environments, it is the necessary equipment

of effective recycling and waste processing systems.

Shredder Components & Construction

In MG machinery company, the Twin Shaft Shredder is a robust system comprised of several key components:

1, Shredding Rotors: The core of the machine, featuring two parallel, counter-rotating steel shafts. Each shaft is equipped with durable

alloy blades for efficient shearing.

2, Drive System: Consists of high-power electric motors and heavy-duty, precision gearboxes that deliver the immense torque required for

shredding tough materials at low rotational speeds.

3, Shredding Chamber & Housing: A reinforced, rigid body constructed from high-strength steel plates. It houses the rotors and provides

the structural integrity to withstand continuous, heavy-load operation.

4, Screening Grid (optional): An interchangeable grate located at the bottom of the crushing chamber. It controls the final output particle

size, allowing material to pass through only once it has been shredded to the desired dimensions.

5, Hydraulic System (optional): An extra unit with hydraulic pusher for pressing the waste materials to rotary shafts with blades to get

efficient shredding, especially for big drums and highly elastic waste.

6, Control System: An integrated PLC-based control panel for easy operation, monitoring, and safety management.

Etc.

Primary Applications & Uses

This Twin Shaft Shredder is versatile and is used to process:

1, Plastics: Lumps, pipes, purging, drums, and mixed plastic waste.

2, Metals: Car parts, aluminum profiles, non-ferrous scrap, electrical appliances, and light gauge metals.

3, Wood: Pallets, construction & demolition waste, root balls, and bulky timber.

4, Rubber waste: old tires from cars and trucks, rubber belt, etc.

5, E-Waste: Computers, printers, and other electronic equipment for material recovery.

6, Other waste: Municipal Solid Waste (MSW), Industrial Waste, and Hazardous Waste for volume reduction.

Scope of Use & Industries

The Twin Shaft Shredder is an essential asset across numerous industries, including:

1, Recycling: In material recovery facilities (MRFs) for plastic, wood, and metal recycling.

2, Waste Management: For volume reduction of industrial and municipal solid waste prior to landfilling or incineration.

3, Automotive & Metalworking: For shredding scrap metal and production waste.

4, Biomass Power: Preparing waste wood and agricultural biomass for fuel.

5, Packaging & Printing: Destroying and recycling off-spec products and materials securely.

The Twin Shaft Shredder is a robust, versatile, and indispensable machine for any operation requiring reliable and efficient size reduction

of complex and bulky materials, driving productivity and sustainability in modern industrial processesarman.

Key Performance Features

1, High Torque & Low Speed: Operates at low RPMs to generate massive torque, enabling it to tear, shear and crush materials that would stall or damage other shredders.

2, Shear-Action Shredding: The interlocking, counter-rotating rotors create a powerful scissor-like cutting action, producing a clean, controlled cut with low dust generation.

3, Toughness & Durability: All critical components, especially the cutting blades and shafts, are manufactured from premium alloy steels and are heat-treated for maximum wear resistance and long service life.

4, Overload Protection: The machine is equipped with automated safety systems to reverse the rotors in case of a jam, preventing damage and ensuring operational continuity.

5, Low Operating Costs: Designed for minimal maintenance, with easily accessible and replaceable wear parts, resulting in reduced downtime and lower long-term costs.

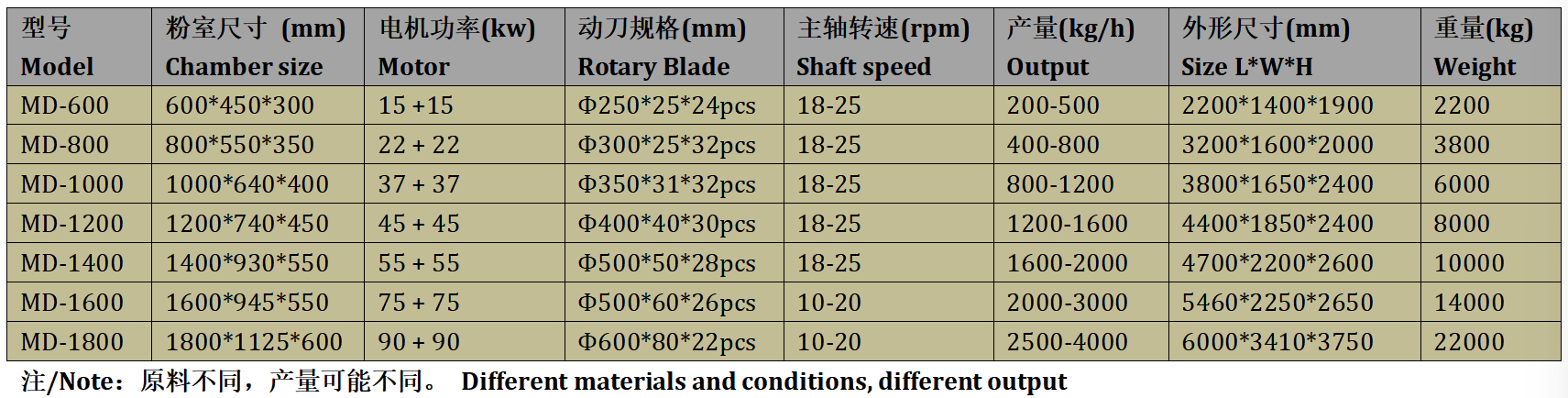

Models of twin shaft shredder in MG Machinery:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.