PET flakes washing machine is used to recycle the waste plastic PET bottles into flakes. It has wide usage for kinds of waste plastic PET bottles, for example, mineral water bottles, cola bottles, juice bottles, oil bottles and PET preforms, etc. The recycled PET flakes are used widely in extrusion and injection factories for production of PET fibers, bottles and films etc.

The PET bottle flakes washing line includes many efficient machines for producing high quality PET flakes, for example, label remover, bottle crusher, hot washer, friction washer, rinsing washer and centrifugal dehydrator, etc. And some auxiliary machines are optional units for increasing the performance of the PET bottle recycling machine, for example, bale breaker, trommel, sorting table and color sorter, etc.

The PET flakes washing machine provides the good solution for recycling the waste PET bottles, the final PET flakes have very high quality, total impurity can be less than 200ppm. Humidity can low than 2% directly by the high speed centrifugal dehydrator, but low power consumption. The PET flakes washing machine has high automation and steady working, less manpower is required.

By different workshop area, Our techinical team will design U or L flowchart of the PET bottle recycling line for different users, and our engineers will help the users to finish the installation, commissioning and training.

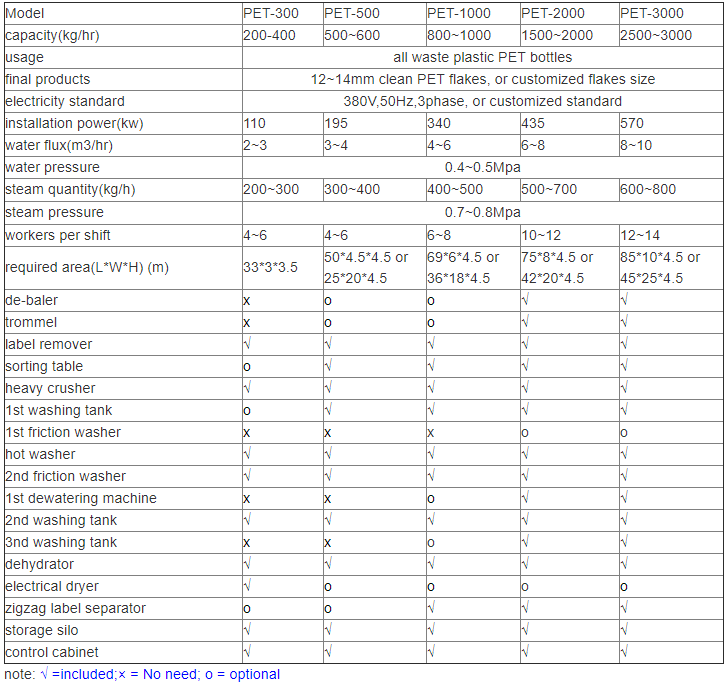

At present, We have standard configuration for 300kg/h to 3000kg/hr PET bottle washing recycling lines for your choice.

Advantage of PET flakes washing machine in MG Machinery:

1, high automation: once normal working, less workers are required for line operation.

2, high PET flakes purity: the removing rate is over 99% for labels and caps. Oil and glue contamination can be washed out by multiple hot washer, high speed friction washer and rinsing tanks.

3, final moisture is less than 2% directly by the special centrifugal dehydrator, no need electrical heater, power saving.

4, PET bottle crusher has SKD-II blades with special mounting angle for efficient cutting, long lifetime. Good pre-washing and rotor cooling function by water spray design.

5, the rinsing tank, screw feeders, pipelines and silo are made of stainless steel, anti-corrosion, long lifetime.

6, thick carbon steel are used for label remover, bottle crusher, belt conveyor and other machine frame, strong enough, less vibration.

7, motors and electrical elements are famous brand such as SIMO and SIEMENS, steady running and safety guarantee.

8, centralized control cabinet with indicators for each unit on the panel, monitor the operation of all units, easy to control the machine running and find out the solution once any fault.

9, reasonable flowchart design to meet the area size of workshop, convenient operation.

Model of PET flakes washing machine in MG Machinery: