In the realm of recycling and sustainable practices, the PET bottle washing line stands as a pivotal technology driving the circular economy. This advanced system is designed to efficiently clean and process used Polyethylene Terephthalate (PET) bottles, transforming them from post-consumer waste into high-quality raw material ready for reintroduction into the manufacturing supply chain.

As the demand for recycled materials continues to grow, the role of the PET bottle washing line will become increasingly important, driving innovation and progress in the recycling industry.

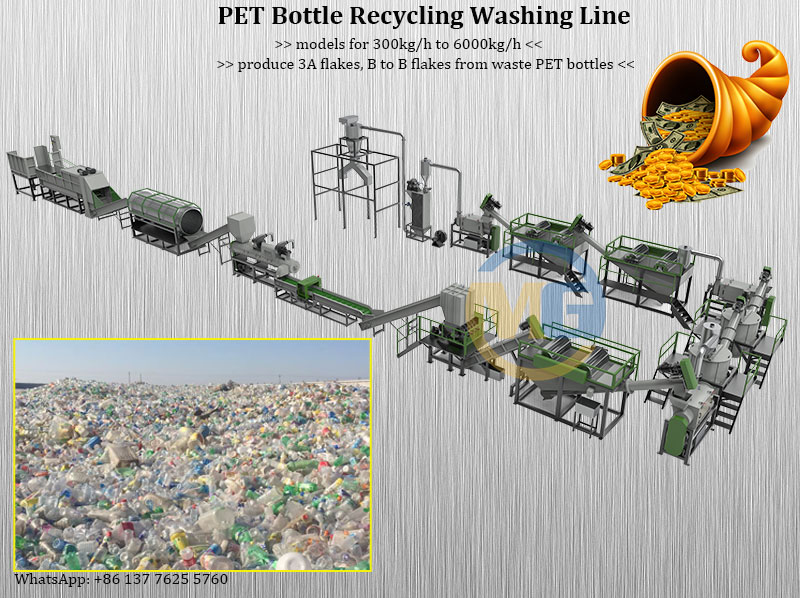

MG's PET bottle washing line is a comprehensive, automated process that encompasses several critical stages: bale breaking, pre-washing,

label removing, sorting, crushing, intensive washing, rinsing, drying and storage. Each stage is meticulously engineered to ensure the highest

standards of cleanliness and purity in the final product, making it suitable for a wide range of applications including food and beverage packaging,

textile fiber production, package strap making, and more.

1, bale breaking: usually, the waste PET bottles are pressed in bales package, so the first step of the recycling washing line is to break the bales and

loose the bottles. And horizontal or vertical bale breaker are optional for use at the beginning, chain plate conveyor is the most reliable unit for move

the bales. But for loose bottles, the bale breaker is not necessary.

2, Pre-Washing: Prior to intensive cleaning, bottles undergo a pre-wash to remove loose dirt, labels, and adhesive residues. This step helps to prepare

the bottles for more effective subsequent cleaning processes.

3, label removing: Waste PET bottles are usually covered with half or full labels on the bodies, it’s very necessary to remove the labels well before

crushing and washing process, which can bring the benefits of saving power, water and detergent consumption. We provide dry label remover design

like the single barrel label remover and 3-barrel label remover machine to meet different removing rate and output requests. And wet label remover is

optional for label removing and pre-washing at the same time.

4, Sorting: The initial step involves separating PET bottles from other types of plastic and contaminants. Advanced sorting technologies, such as optical

sorters, utilize cameras and sensors to accurately identify and segregate PET bottles based on color, shape, and material composition. For for lower

investment demand, the manual sorting system provides an economical solution.

5, Crushing: The bottles are then crushed into smaller flakes or chips, which increases the surface area for more efficient washing and reduces the overall

volume for easier handling and processing. Heavy type crusher machines are mostly used in the PET bottle recycling industry.

6, Intensive Washing: This stage employs specialized washing machines that use a combination of hot water, detergents, and

mechanical agitation to thoroughly clean the flakes. The washing process removes oils, sugars, and other residues that may be

present on the bottles. Usually It's very helpful to install a screw friction washer and a washing tank before the hot washer, which

can scatter the PET flakes and separate most float materials like the cap and ring flakes, as well as some remain label.

7, friction washing and rinsing: After the intensive wash, the PET flakes are sent into the high speed friction washing to remove the

tough dirties like glue, then the PET flakes are rinsed with clean water to ensure all detergent residues are removed, leaving the material pristine.

8, Drying: The washed flakes are then passed through a high speed dehydrator machine with 2000rpm rotary speed for dewatering,

the moisture can be less 2 after this machine. For further drying requirement, an electrical drying system is optional, typically using hot air,

to reduce their moisture content to acceptable levels for further processing or storage.

9, storage. After washing and drying ,the clean flakes are usually blown into a big storage silo for easy package of jumbo bags.

Waste plsatic PET bottles

With the development of social economy, a large number of waste plastic bottles are produced in our daily life. And the bottles already make the pollution to the evironment in sea, river and farmland, etc.

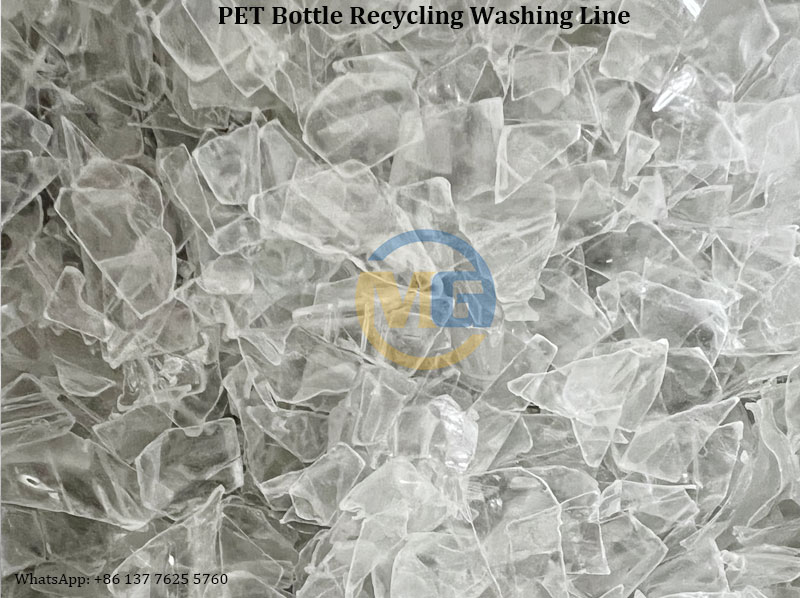

PET flakes

How to recycle such waste PET plastic bottles? And what quality PET flakes will you get after the recycling?

For 10s years dvelopment in the waste plastic recycling machine industry, we understand that a good recycling washing line is very important for a plant to solve the plastic bottle pollution and produce high quality PET recycled flakes. Therefore, as a munfaucture the the PET bottle recycling machines, we are keeping on the pursue of the better and better machine technics for the pet washing lines.

Our PET bottle recycling washing lines can help you to produce the qualified PET flakes with the following benchmarks:

Flakes size: < 6-16mm

Moisture content: < 2%

Bulk density: 300±100KG/M3

Total impurity: < 150ppm

PVC content: < 30ppm

Glue and labels: <20%

Metal content: < 10ppm

PE/PP content: < 30ppm

For other requirements on the PET flakes, please contact us freely.

The advantages of PET bottle washing lines in MG machinery company:

1, High Efficiency in recycling, different models for different capacity requirement, reasonable flowchart for good recycling result.

2, High Automation: The adoption of automated control systems reduces manual intervention, improves production efficiency, and lowers labor costs.

3, Energy and Emission Reduction: The cleaning process incorporates energy-saving designs, reducing water and energy consumption, and aligning with environmental protection requirements.

4, High Product Quality:

1)Food-Grade Standards: Through advanced cleaning processes and strict quality control, the recycled PET raw materials can meet food-grade standards, suitable for producing food packaging materials.

2)Low Impurity Content: The cleaning process effectively removes impurities such as labels, metals, and plastic debris from the bottle flakes, enhancing the purity of the recycled PET raw materials.

4, Wide Application Range: The PET bottle washing line can handle various types of PET bottles, including mineral water bottles, carbonated beverage bottles, juice bottles, etc.

5, Flexible Configuration: The PET bottle washing line can be customized according to customer needs, including label removing (stripping), crushing, cleaning, drying, packaging, and other processes.

Etc.

These advantages make the PET bottle washing line a valuable investment for companies looking to engage in sustainable and environmentally friendly practices while also benefiting economically.

4, strong machine structure designs ensure the steady running in long lifetime.

5, stainless steel SUS304 are used for all screw feeders, hot washer, washing tanks, screens, silo and pipelines.

6, the motors and electrical elements are famous brands products such as SIEMENS, WN and OMRON for safety guarantee.

7, steady working in long lifetime.

8, quality certification.

etc

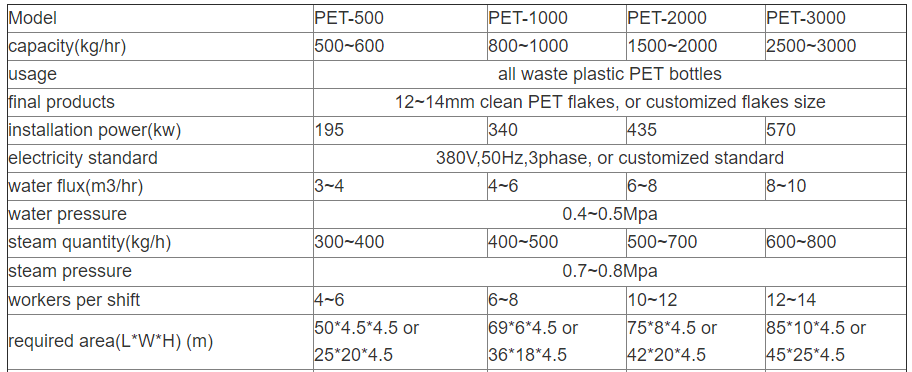

Models of plastic PET bottle washing line in MG machinery company

What we can do for you for the cooperation:

1, machine proposal suggestion: according to the waste plastic conditions in your factory, we will provide the most suitable proposa of the whole PET bottle recycling washing line for you. But customized machines are also available.

2, workshop layout planning: Regards to the confirmed proposal of PET bottle recycling washing line, our technical team will design the reasonable layout for the line to maximize the usage of your workshop area.

3, quality guarantee for machine steel and components: ensure the steel type, motors and electrical compenents are the same as the confirmed ones.

4, skilled workers for machine manufacturing.

5, machine testing well before shipment.

6, delivery on time according to confirmed machines or production lines.

7, engineer service to your factory on time.

8, cost price for machine parts that need to be replaced.

9, service for machine lifetime.

Etc.

Our plastic recycling machines and extrusion machines have been exported to many countries, for example, Japan, USA, Thailand, Vietnam, Maylasia, Indonesia, Mexico, Chile, Argentina, brazil, India, Napel, Russia, Urkaine, UAE, Saudi Arabia, Russia, Israel, Ghana, Serbia, Geogia, Togo, Kenya, etc.