The PET Flakes Hot Washing Machine is a specialized equipment designed for the efficient cleaning of PET flakes in hot water by working together with chemical detergent. This machine plays a crucial role in the waste PET bottles recycling industry, ensuring that waste PET bottles are transformed into clean and reusable flakes.

The primary function of the PET Flakes Hot Washing Machine is to thoroughly wash PET flakes in the recycling washing line. It effectively removes dirt, oil, grease, and other contaminants that may be adhered to the flakes surfaces. The hot washing process utilizes high-temperature water and specialized cleaning agents to break down and eliminate these impurities, leaving the PET flakes clean and ready for further processing.

Design

The PET Flakes Hot Washing Machine is engineered with a robust and durable design to withstand the rigors of continuous operation. It features a stainless steel construction that is resistant to corrosion and wear, ensuring long-term reliability. The machine is equipped with a high-efficiency heating system that quickly and evenly heats the water to the desired temperature, optimizing the washing process.

The design also incorporates advanced agitation and filtration systems. The agitation system ensures that the plastic materials are thoroughly mixed with the cleaning solution, enhancing the cleaning efficiency. The filtration system, on the other hand, removes the suspended contaminants from the washing water, maintaining a clean and effective cleaning environment.

On the PET flakes hot washer machine, electrical heaters are installed at the machine bottom for heating the water directly. But if the users have other fuel requirement, for example, natural gas and oil, We can change the heating system accordingly.

The PET Flakes Hot Washing Machine offers numerous advantages as following.

1, Efficient Cleaning:

The hot washing process utilizes high-temperature water and specialized cleaning agents, which effectively break down and eliminate dirt, oil, grease, and other contaminants from the plastic surfaces.

This results in cleaner plastic flakes or pellets, improving the overall quality of the recycled or processed material.

2, Time and Cost Savings:

By efficiently cleaning the plastic materials, the Plastic Hot Washing Machine reduces the need for additional cleaning steps or manual labor, saving time and labor costs.

Cleaner plastic materials also require less processing time and energy in subsequent stages, such as extrusion or molding, further reducing costs.

3, Enhanced Product Quality:

The thorough cleaning provided by the machine ensures that the plastic materials are free from impurities, which can affect the final product's appearance, performance, and durability.

This leads to higher-quality finished products that meet or exceed customer expectations.

4, Versatility and Flexibility:

The Plastic Hot Washing Machine is designed to handle a wide range of PE and PP hard plastics, making it a versatile solution for various industries and applications.

Its adjustable washing parameters allow for customization according to the specific needs of different plastic materials and contamination levels.

5, Durability and Reliability:

The machine's robust design and stainless steel construction ensure long-term durability and resistance to corrosion and wear.

This reduces the need for frequent repairs or replacements, further saving costs and minimizing downtime.

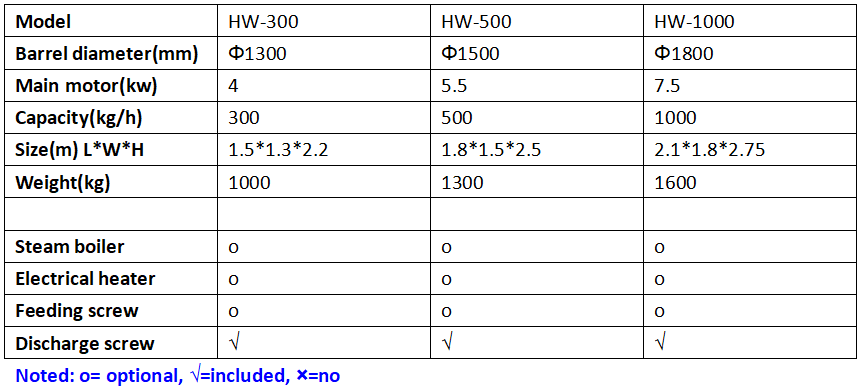

Models of PET flakes hot washing machine in MG Machinery:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.