The high speed friction washer is an innovative device specifically designed for the waste plastic recycling industry. Utilizing advanced friction technology, this equipment efficiently cleans and processes plastic materials at high speeds. It effectively removes dirt, oils, and other contaminants, ensuring that the recycled plastic meets high-quality standards. With its superior cleaning performance and rapid processing capabilities, the high speed friction washer is a valuable addition to any waste plastic recycling facility, enhancing recycling efficiency and promoting sustainable practices.

The high speed friction washer for waste plastic recycling works by utilizing friction forces to clean and process the plastic materials.

When plastic waste is fed into the high speed friction washer, it comes into contact with rotating or oscillating surfaces within the machine. These surfaces move at high speeds, generating friction against the plastic particles. The friction forces help to loosen and remove dirt, oils, labels, and other contaminants that are adhered to the plastic surfaces.

As the plastic materials pass through the machine, they are subjected to repeated cycles of friction, which gradually strip away the impurities. The cleaned plastic particles are then collected and ready for further processing or reuse. The high speed operation ensures that the cleaning process is efficient and effective, making the high speed friction washer an invaluable tool in the waste plastic recycling washing industry.

The high speed friction washer for waste plastic recycling offers several advantages, making it a highly sought-after equipment in the industry.

1, Efficient Cleaning: The high-speed friction mechanism effectively removes a wide range of contaminants, including dirt, oils, labels, and adhesives, ensuring that the recycled plastic is of high quality.

2, Rapid Processing: The high-speed operation of the washer allows for quick processing of large volumes of plastic waste, significantly increasing recycling efficiency and throughput.

3, Energy-Saving: By utilizing mechanical friction instead of chemical treatments or heat, the high speed friction washer consumes less energy, making it a more environmentally friendly option.

4, Versatility: This equipment can handle both hard plastic flakes and soft plastic films and bags in the plastic crusher washing line.

5, Cost-Effective: The high speed friction washer reduces the need for additional cleaning steps or equipment, lowering overall recycling costs and improving profitability.

The high speed friction washer is a reliable, efficient, and cost-effective solution for waste plastic recycling, offering numerous benefits to recycling facilities and contributing to a more sustainable future.

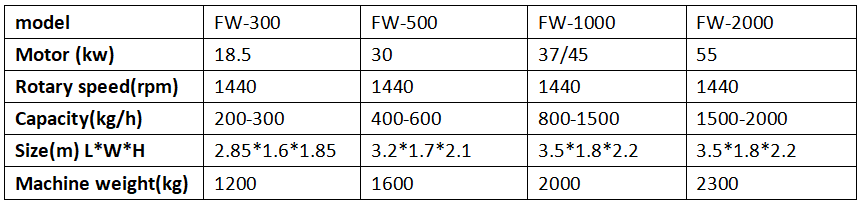

Models of horizontal high speed friction washer machine in MG Machinery:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.