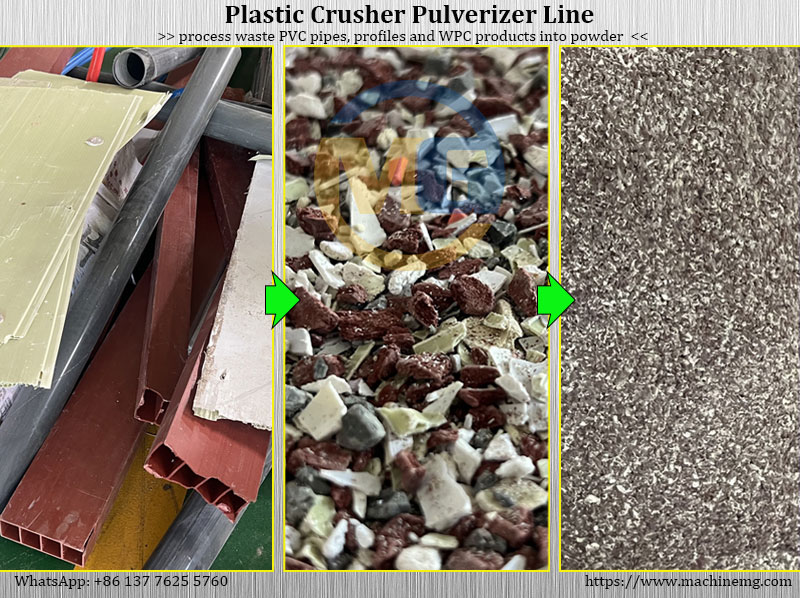

The PVC Crusher and Pulverizer Production Line is a highly efficient and versatile system designed for the processing and recycling of waste PVC materials. This production line is developed to meet the growing demand for sustainable and eco-friendly solutions in the plastic processing industry.

The primary purpose of the PVC Crusher and Pulverizer Production Line is to convert waste or scrap PVC materials into finer particles suitable for recycling or reuse in various applications, for example, PVC window frames, PVC door boards, PVC pipes, PVC wall claddings, PVC fence profiles, and PVC WPC products, etc. This not only reduces the environmental impact of PVC waste but also provides a cost-effective solution for the plastic processing industry.

Composition of the Production Line

The PVC Crusher and Pulverizer Production Line comprises several key components, each playing a crucial role in the recycling process. These include:

1, Crusher: The crusher is the heart of the production line. It reduces the size of waste PVC materials into smaller fragments, making them easier to handle and process. The crusher is equipped with high-quality knives and a robust frame to handle the tough nature of PVC waste.

2, Conveyor System: This system transports the processed PVC particles from one stage to another, ensuring a smooth and efficient workflow throughout the production line. Screw loader of cyclone conveyor are mainly used as conveyor system. And the screw loader will make less dust while the conveying.

3, Pulverizer: Following the crusher, the pulverizer further refines the PVC fragments into finer particles or powder. This stage is crucial for achieving the desired materials size for recycling or reuse.

On the PVC pulverizer machine, screening system is for separating the pulverized PVC particles into different sizes based on the application requirements. It ensures that the final product meets the specified standards for quality and consistency. The unqualified materials will be send back to the pulverizer automatically for milling again.

Dust collector is also installed on the PVC pulverizer system, to capture most fugitive dust generated during the processing, and maintain a clean and safe working environment,

4, Feed System (optional): This component is an optional unit for conveying the waste PVC profiles into the crusher machine. Since the PVC crusher has long and inclined feeding inlet, the feed system has lower efficiency than manual feeding while for the long profiles and pipes.

5, Control Cabinet: for centralized control of the whole line working.

The PVC Crusher and Pulverizer Production Line offers a comprehensive solution for the recycling and reuse of waste PVC materials. Its high efficiency, versatility, and eco-friendly nature make it an ideal choice for the PVC processing industry.

Advantages of the PVC Crusher and Pulverizer Production Line in MG machinery company.

1, High Efficiency and Productivity:

The production line is designed to operate at high speeds and with high throughput, enabling it to process large volumes of waste PVC materials quickly and efficiently.

The crusher and pulverizer are equipped with advanced technology and robust components, ensuring continuous and reliable operation with minimal downtime.

2, Precision Processing:

The production line is capable of achieving precise particle size distribution, meeting the strict requirements of various recycling and reuse applications.

The screening system effectively separates particles into different sizes, ensuring the final product meets the specified quality standards.

3, Versatility:

The production line is versatile and can handle a wide range of PVC materials, including PVC pipes, profiles, sheets and board, etc.

It can process PVC materials of various sizes, shapes, and compositions, making it suitable for a wide range of applications in the construction, automotive, electronic, and other industries.

4, Cost-Effectiveness:

The production line offers a cost-effective solution for PVC recycling and reuse, reducing the need for virgin PVC materials and lowering production costs.

The efficient processing and high productivity contribute to lower overall operating costs.

5, Ease of Operation and Maintenance:

The production line is designed with user-friendly controls and intuitive interfaces, making it easy to operate and monitor.

The robust components and durable design reduce the need for frequent maintenance and repairs, further enhancing the overall cost-effectiveness of the system.

Etc.

The PVC Crusher and Pulverizer Production Line offers a range of advantages, including high efficiency, precision processing, versatility, cost-effectiveness, environmental sustainability, ease of operation and maintenance, and compliance with standards. These advantages make it an ideal solution for the recycling and reuse of waste PVC materials in various industries.

In MG machinery company, we provide the PVC crusher and pulverizer production lines with capacity from 100kg/h to 1000kg/h, And our technician team will prepare the precise equipment proposal according to the real conditions of your waste PVC materials or other plastic waste.

Please contact us on WhatsApp, Wechat or send a mail directly with your detailed requests, thank you.

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.