Dual-Shaft Metal Shredder: The Ultimate Solution for Industrial Scrap Processing

The heavy-duty Dual-Shaft Shredder is engineered to be the cornerstone of your metal recycling and size reduction operations. Designed

for maximum durability and efficiency, it tackles the toughest metal scrap, including mixed metals, car bodies, manufacturing waste,

copper cables, aluminum cans and white goods, etc.

How the metal shredder works

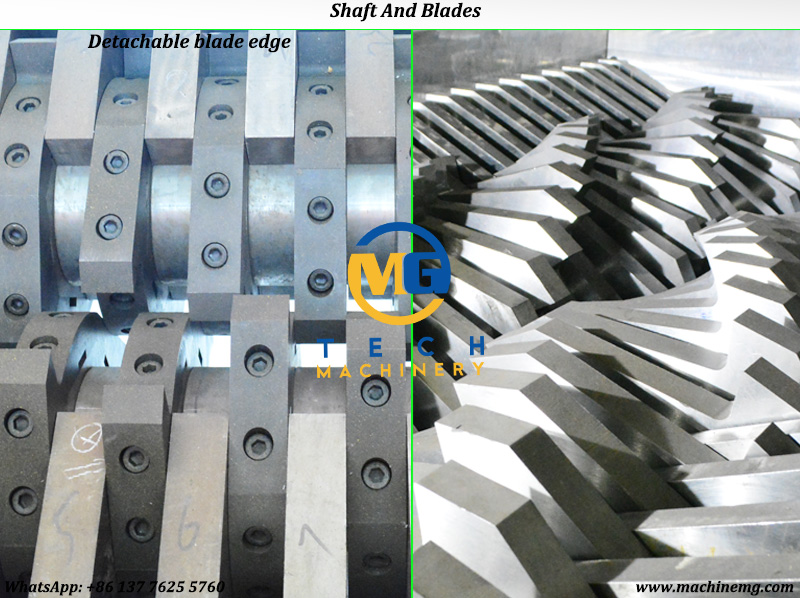

Utilizing two counter-rotating shafts fitted with hardened, interchangeable alloy blades, the shredder machine applies powerful shearing

and tearing forces. This "slow-speed, high-torque" action progressively reduces bulky, irregular metal scraps into controlled and smaller

chips. An intelligent control system provides auto-reverse functions and overload protection to prevent damage and ensure continuous

operation.

Application:

1, Aluminum can bundle, steel drum, paint barrels and tanks, gas tanks, zip top cans.

2, engine cases, copper aluminum readiator, oil filters, car shells, old bikes,

3, color steel tiles, metal sheets, metal leftover materials.

4, scrap wires, copper cables, steel wire ropes, etc.

5, aluminum composite plastic profiles.

Refence Video on YouTube Channel:

twin shaft shredder for metal waste

Consists of the metal shredder machine

1, Feeding hopper: As the inlet for feeding the waste metals into the chamber for shredding, deep inlet design is necessary to avoid the materials ejection while shredding. two optional designs: vertical feeding hopper or side feeding hopper.

2, Driving System: powerful motor and reducer are chosen for the shredders, ZY cylinder gear reducers are used for the metal shredders, high transmission efficiency, higher bearing ability, steady working, long lifetime. The motor brands could be customized for example, WN, SIEMENS, ABB, etc.

3, Cutting shredding system: two shafts with more diameter, stationary and rotary blades are made of H13 with more hardness and good durability, thick steel boards are used for making the chamber walls. Different claw blades with more thickness are optional according to the shredding requirements.

4, Feeding and Discharging units: As usual, belt conveyors can be used for feeding the waste materials and conveying the shredded materials out from the bottom of the twin shaft shredders.

5, Machine frame: use thick carbon steel tubes and boards for making the strong machine frame, with anti rust treatment.

6, control cabinet: centralized control system is used for the running control of the twin shaft shredder for metal shredding, easy operation. Famous brands electric components and parts are installed, for example, SIEMENS or SCHNEIDER contactor, SIEMENS PLC module, etc.

Key Features & Benefits:

1, Unmatched Durability: Constructed with high-strength, wear-resistant steel plates and cutting rotors treated for extended service life, capable of withstanding shock loads and abrasive materials.

2, High Torque Power: Delivers massive tearing force for the most demanding applications, efficiently processing a wide range of ferrous and non-ferrous metals.

3, Volume Reduction & Profitability: Dramatically decreases the volume of your scrap, leading to lower transportation costs, easier handling, and higher value in the recycling market.

4, Versatile Application: Effectively processes various materials from light gauge metals to entire end-of-life vehicles (ELVs) and aluminum profiles.

5, Low Operating Costs: Designed for minimal maintenance and energy consumption, featuring a robust design that reduces downtime and maximizes your return on investment.

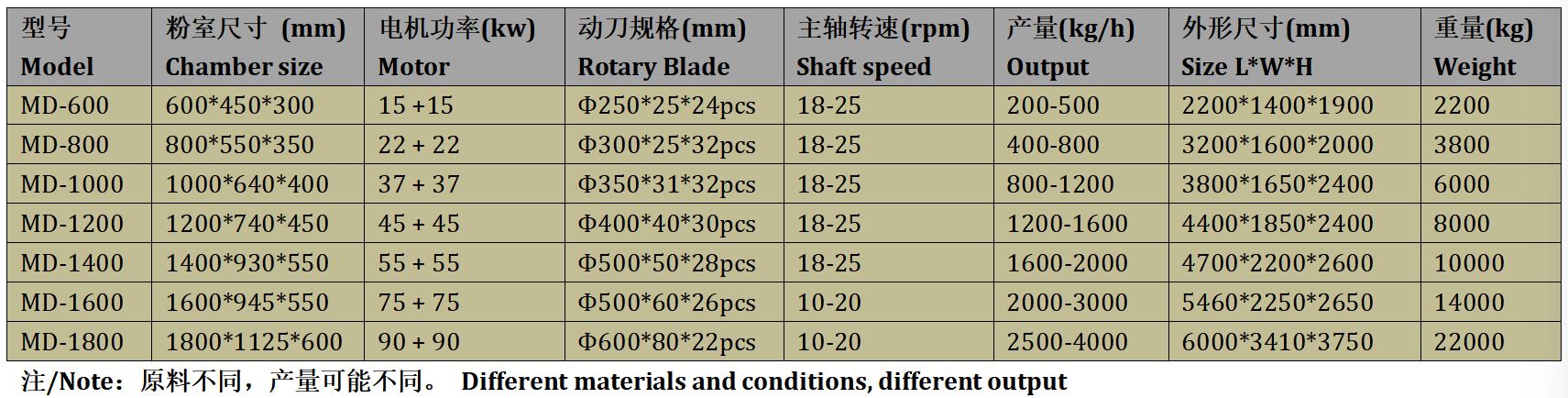

Models of metal shredder machine in MG Machinery company:

Why choose us?

1, provide the right shredder models and proposals according to your requirement quickly.

2, professional designs of machine flowchart and workshop layout quickly

3, best quotation for same level shredder machine from China.

4, high machine manufacturing technics and strict quality requirements.

5, complete machine testing to confirm the high performance parameter before shipment.

6, shipment on time. And we can help on ship booking, container loading with good fastening in factory

7, dispatch engineer for after sale service in your company on time

8, training for machine and operation.

9, technology support all lifetime.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.