Engineered for Efficiency in Automotive Plastic Recycling

The heavy-duty Car Bumper Shredder, with twin shaft design, is the cornerstone of a profitable plastic recycling operation. Specifically

designed to handle the challenging size and material composition of PP and ABS bumpers, this robust machine transforms bulky, difficult

-to-manage waste into small scraps for further recycling process.

Ideal for end-of-life vehicle (ELV) processors and plastic recycling facilities, this twin shaft bumper shredder turns automotive plastic waste

into a valuable resource. Request a free consultation to design your optimal recycling solution.

To meet different material size requirement after shredder, the users can choose different cut blades for the bumper shredders, for example, 1-claw blade, 2-claw blade, 3-claw blade and 5-claw blade, etc.

Core Features & Benefits of the bumper shredder machine:

1, Robust Twin-Shaft Design: Features a low-speed, high-torque cutting system that delivers high throughput with minimal noise and dust, ensuring reliable operation and reduced wear.

2, Profit-Driven Performance: Dramatically reduces the volume of scrap bumpers, cutting down on storage space and transportation costs while preparing material for the next stage of granulation.

3, Customizable Configuration: Built to integrate seamlessly into a full bumper recycling line, capable of being customized with specific screen sizes and downstream sorting systems to meet your precise output requirements.

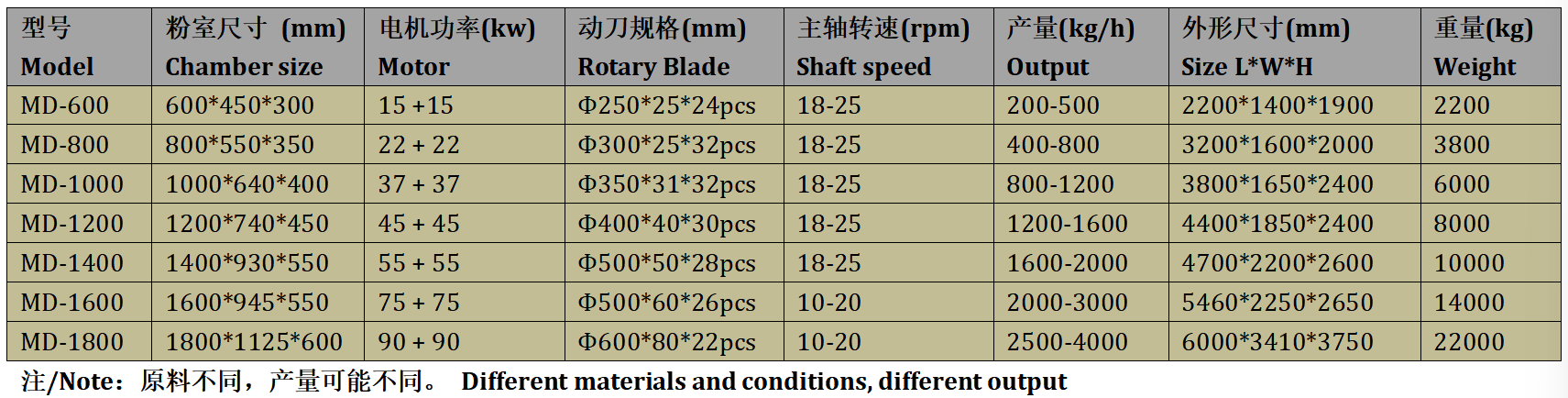

Models of plastic bumper shredder in MG Machinery:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.