Rigid PP PE Plastic waste washing line consists of heavy crusher, strong friction washer, floating sinking washing tanks, centrifugal dewatering machine, cyclone system and centrilized control system.

It's a very efficient plastic waste washing line to recycling the ridig plastic waste, especially for the PP PE hard waste materials, for example, kinds of wate PP PE bottles as milk bottles, shampoo bottles and detergent bottles, oil tanks, chemical tanks, plastic trays, fruit baskets and crates, plastic pallets, plastic shells from waste TV, refrigerators, computers and air conditioners, waste car bumpers, plastic drums, etc.

By this plastic waste washing recycling machine, the final products are clean flakes with indicated sizes, which can be reused in extrusion, injection and blow molding directly or after pelletizing.

Small and middl size rigid waste plastic materials can be fed into the crusher of this plastic washing line directly for processing, but for some waste plastics with big size and more thickness, a single shaft shredder or twin shaft shredder should be used before the crusher machine for coarse crushing, for example, plastic lumps, big drums and IBC tanks, etc.

Advantages of the rigid PP PE plastic waste washing line in MG Machinery:

1, high working efficiency.

2, less power consumption.

3, high automation, labor saving.

4, heavy crusher has alloy blades with special mounting angle for efficient cutting, long lifetime. Good pre-washing and rotor cooling function by water spray design.

5, strong friction washer brings the powerful washing to clean the mud, soil and sticking dirties, and with conveying fuction directly to next washing machine.

6, by multiple friction washing and rinsing washing, the dirties can be washed out fully.

7, high dewatering rate by efficient dehydrator machine, no need any heating dryer again, save the running cost.

8, the rinsing tank, screw feeders, pipelines and silo are made of stainless steel, anti-corrosion, long lifetime.

9, motors and electrical elements are famous brand such as SIMO and SIEMENS, steady running.

10, strong machine structure and good balance performance for steady working in long lifetime.

11, reasonable flowchart design for convenient operation and lower maintenance cost.

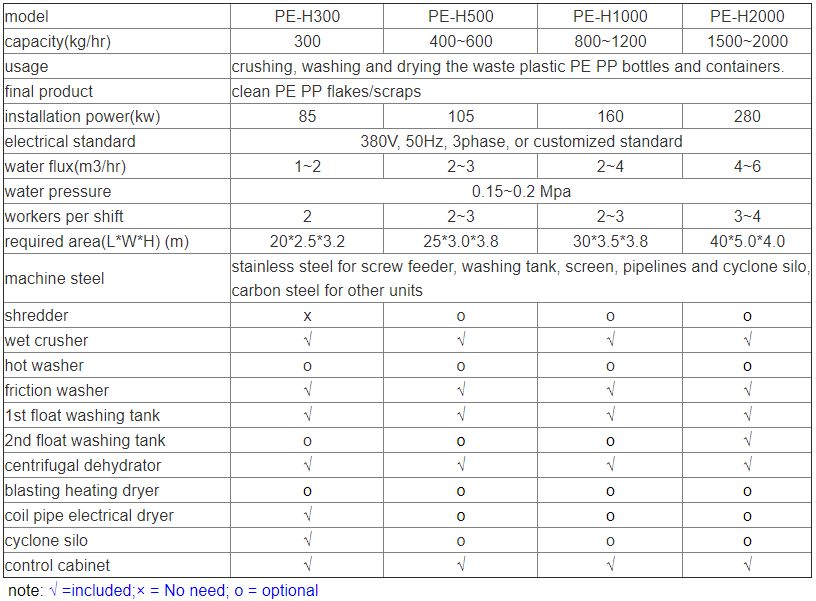

Models of rigid PP PE plastic waste washing line in MG machinery company:

What we will do for you in the cooperation:

1, free proposal quotation,

2, free flowchart and layout design.

3, the top level processing technics for the machines and mould in China same industry.

4, update information according to production schedule.

5, delivery on time.

6, free formula technology support

7, after sale service on time.

8, new technology sharing freely.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007, for example, Japan, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Geogia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.