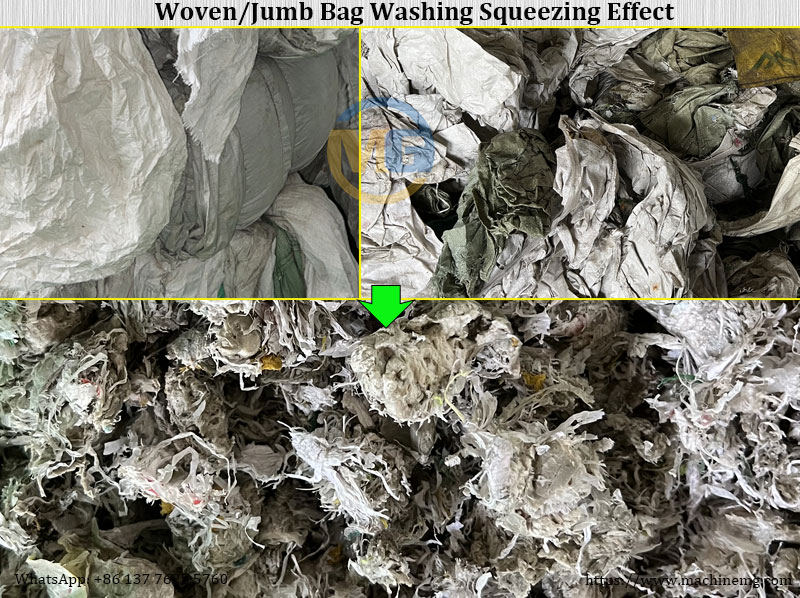

The PE PP Plastic Film Washing Line includes plastic squeezer for working together, It is a comprehensive solution designed for the efficient recycling and processing of waste polyethylene (PE) and polypropylene (PP) plastic films. This advanced plastic washing line is engineered to meet the increasing demand for sustainable waste management and resource recovery. It is capable of processing a wide range of PE and PP plastic films, including waste packaging materials, agricultural films, and industrial waste plastics, meanwhile, it can process the PP bags also for effcient recycling, for example, woven bags, jumbo bags, and other sack raffia materials. The washing line effectively removes contaminants, such as dirt, labels, and adhesives, from the plastic films, restoring them to a high-quality, reusable state.

The PE PP Plastic Film Washing Line is characterized by its streamlined and efficient design. The entire system is fully automated, ensuring high throughput and consistent quality output. The design incorporates the latest technology in plastic recycling, making it both user-friendly and highly effective.

The plastic film washing line is composed of several key components, each playing a crucial role in the recycling process. The main components include:

1, Feed Conveyor: This machine transports the raw waste plastic film materials into the system.

2, Shredder and (or) Crusher: This equipment breaks down the plastic films into smaller pieces, facilitating subsequent processing steps. According to the real condition of plastic films, the shredder and crusher machines are optional, sometimes, either of the two is enough in the washing line, but for some big and tough materials, shredder and crusher must be used together in the washing line.

3, Friction Washing Machine: This machine uses friction force to clean the plastic pieces, removing impurities and dirt. Two friction washers are usually used in the line design of MG machinery company, one is screw friction washer at middle speed 640rpm, the other one is high speed friction washer of which the speed can be up to 2000rpm.

4, Rinsing Tanks: These tanks use water to further cleanse the plastic pieces, ensuring high purity. By the floating design, it can also separate the heavy materials out from the PE/PP films.

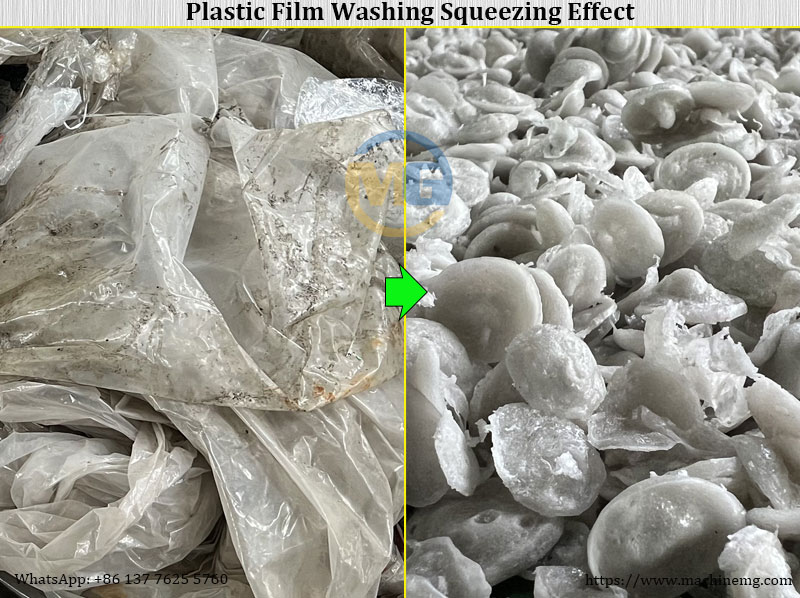

5, Squeezer for drying: This machine removes excess moisture from the cleaned plastic pieces and agglomerate the films directly, achieve high moisture removing over 95%, and size reduction more than 50%.

6, screw loader: as a connection unit, it is used for transferring the wet films fragments in the line.

7, centralized control cabinet: it is used to to monitor and regulate the entire process.

Besides the above basic machines, there are also some auxiliary machines as optional units to the PE PP plastic film washing line, for example,

1, film bales breaker: likes 9-grid slitting machine,

2, hot washer: for cleaning the tough dirty such as oil contamination.

3, plastic and paper separator: some films may include labels, this separator provide strong friction washing force to remove such labels.

4, waste water treatment system: it is used to recycle the dirty water out from the plastic film washing process, after treatment, the water can be reused for washing.

Etc.

What's the usage of clean plastic film?

The recycled plastic films produced by the PE PP Plastic Film Washing Line have a multitude of applications. They can be used in the production of new plastic films, sheets, and bags, reducing the demand for virgin plastic materials. Additionally, the recycled plastics can be used in the manufacturing of various products, such as automotive parts, building materials, and consumer goods. This not only helps in reducing waste but also contributes to energy conservation and environmental protection. But for deep recycling, the plastic pelletizing machines are required to process the clean plastic film into pellets.

the PE PP Plastic Film Washing Line is a versatile and efficient solution for the recycling of PE and PP plastic films. Its advanced design and composition make it capable of handling large volumes of waste plastics, transforming them into valuable resources for various industries.

The advantages of the PE PP Plastic Film Washing Line in MG Machinery company:

1, High Efficiency and Automation

The plastic film washing line adopts fully automatic control, featuring a compact and reasonable layout for high production efficiency.

Equipped with advanced automation equipment and control systems, it reduces manual intervention and enhances productivity.

2, Strong Processing Capability

Designed to handle large volumes of waste PE, PP films, woven bags, and other plastic materials.

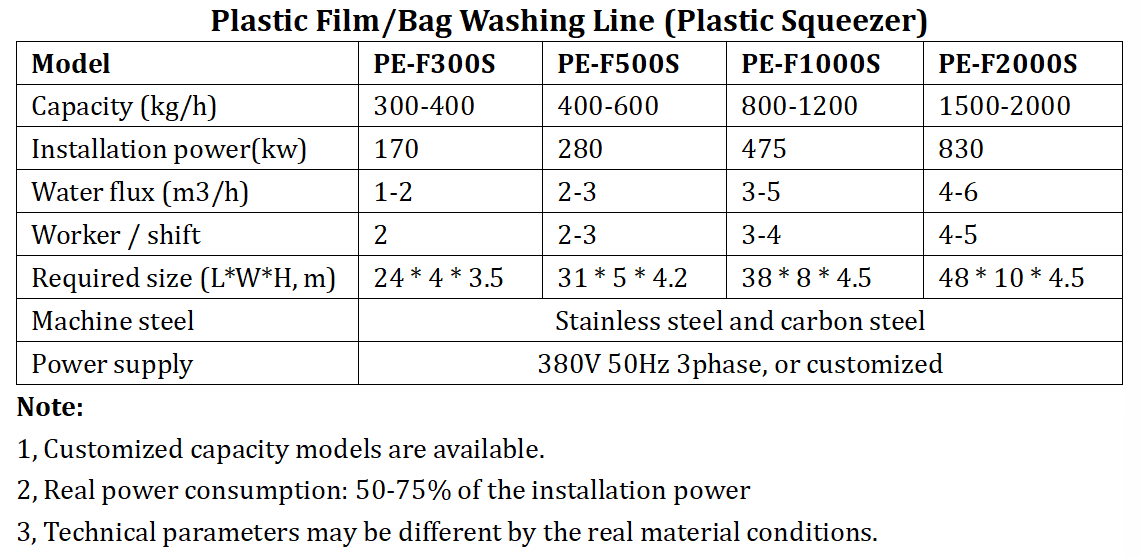

The plastic film washing line boasts high output capacity, with some models capable of processing 300-2000 kilograms per hour, meeting the demands of large-scale plastic recycling.

3, Excellent Cleaning Effect:

The plastic film washing line includes a multi-stage cleaning system, such as rinsing and high-speed frictional washing, ensuring thorough cleaning of plastic films.

The cleaned plastic films have low moisture content and high quality, making them suitable for further processing.

4, Energy-saving and Environmental Protection

The film washing line is designed with a focus on energy conservation and consumption reduction. For example, some models are equipped with film squeezers, eliminating the need for electric heating drying systems and saving electricity.

Water consumption is low, and some systems enable water reuse, reducing water resource consumption.

4, Durability and Reliability

The plastic film washing line is manufactured using high-quality materials, with core components such as PLC, engines, and bearings being durable and reliable.

A long warranty period is provided, ensuring customers have peace of mind.

5, Flexibility and Customization:

The plastic film washing line can be customized according to specific customer needs and material characteristics, catering to different industries and application scenarios.

Available models of PE PP Plastic Film Washing Line with squeezer machine in MG Machinery company:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.