The Hard PE PP Plastic Washing Line is meticulously designed to meet the rigorous demands of the plastic recycling industry. Featuring

a robust and durable construction, this advanced equipment is engineered to ensure high-efficiency and reliable performance.

The primary function of the Hard PE PP Plastic Washing Line is to effectively clean and process hard PE and PP plastics. It removes

contaminants such as dirt, oil, and labels, leaving the plastic material clean and ready for further processing. The equipment utilizes

advanced washing techniques and technologies to ensure thorough cleaning and high-quality output.

The hard PE PP plastic washing line incorporates a series of specialized components, including:

1, belt conveyor: This machine transports the raw waste plastic film materials into the system.

2, screw loader: as a connection unit, it is used for transferring the wet plastic flakes fragments in the line.

3, shredder (optional): as a coarse crushing solution before crusher, for cutting the large plastic waste into small pipes, for example,

chairs, pallets, IBC tanks, blue drums, etc. Single shaft shredder or twin shaft shredder are optional for using according to the waste

conditions.

4, crusher: heavy structure crusher machine are used in this washing line, it can process the small and middle size waste hard PE PP

plastic directly, for example, small tanks, baskets, milk bottles, shampoo bottles, detergent bottles, etc.

5, Rinsing Tanks: These tanks use water to further cleanse the plastic pieces, ensuring high purity. By the floating design, it can also

separate the heavy materials out from the PE/PP flakes.

6, hot water tank (optional): for cleaning the tough dirty such as oil contamination.

7, friction washer: This machine uses friction force to clean the plastic pieces, removing impurities and dirt. Two friction washers are

usually used in the line design of MG machinery company, one is screw friction washer at middle speed 640rpm, the other one is high

speed friction washer of which the speed can be up to 2000rpm.

8, dehydrator: This machine removes excess moisture from the cleaned plastic pieces, preparing them for the next stage, its' rotary

speed is up to 2000rpm, the final moisture can be lower than 2% by one time process. If no higher demand on moisture, it is not

necessary to electrical dryer again, and it help to save power.

9, electrical dryer: auxiliary machine to dry the plastic flakes to meet higher requirement on the moisture.

10, cyclone system: for storage of the clean plastic flakes temporarily.

11, control cabinet: it is used to to monitor and regulate the entire process.

Etc.

Each component is carefully selected and integrated to create a seamless and efficient recycling process.

The application scope of the Hard PE PP Plastic Washing Line is wide-ranging. It is ideal for recycling facilities, plastic processing

plants, and waste management companies. Whether you are dealing with post-consumer or post-industrial plastic waste, this washing

line can handle the job with ease. Invest in our Hard PE PP Plastic Washing Line today and take your recycling operation to the next

level.

Advantages of the Hard PE PP Plastic Washing Line in MG machinery company:

1, Efficient Cleaning: The Hard PE PP Plastic Washing Line is designed to efficiently clean hard PE and PP plastics, removing contaminants such as dirt, oil, and labels. This ensures high-quality output material that is ready for further processing.

2, Durable and Robust: The machines of the line are constructed with durable materials and components, making it robust and capable of withstanding the rigors of the recycling process. This ensures long-term reliability and reduced downtime.

3, Modular Design: The hard plastic washing line features a modular design, allowing for easy integration and customization to meet specific processing needs. This flexibility makes it a versatile solution for various recycling applications.

5, Energy-Efficient: The equipment is designed to be energy-efficient, reducing operational costs and environmental impact. This is achieved through optimized component design and efficient process flow.

6, High Capacity: The hard plastic washing line can handle large volumes of plastic material, making it suitable for high-throughput recycling operations. This increases productivity and reduces processing time.

Etc.

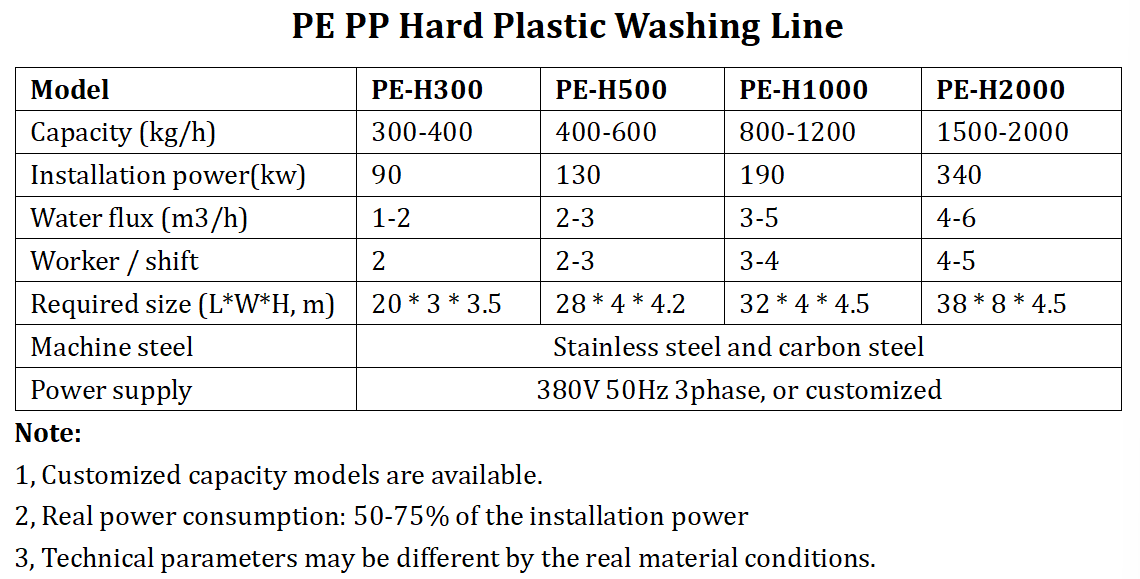

Models of Hard PE PP Plastic Washing Line in MG machinery company:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.