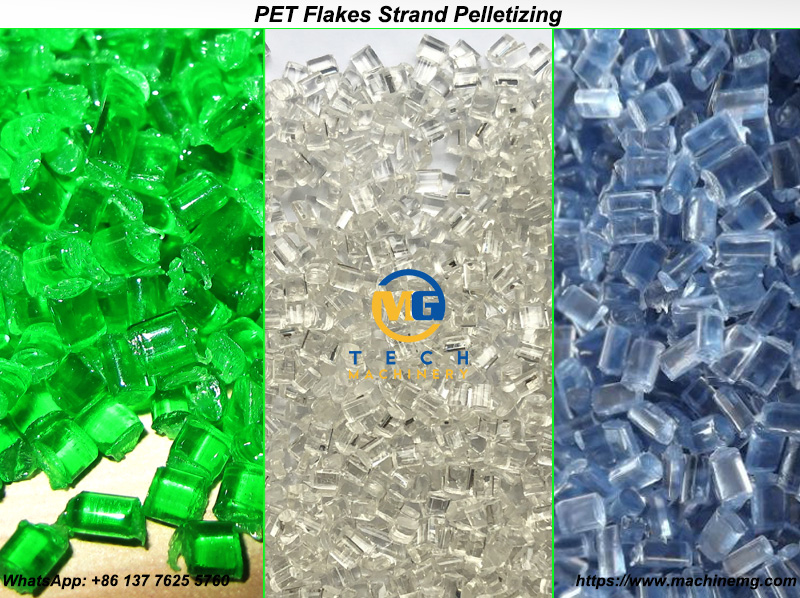

PET Pelletizing machine is used for waste PET flakes pelletizing production. The whole pelletizing line includes parallel twin screw extruder, filtration unit, strand mold, water cooling tank and gantry pelletizer cutter, etc. Through the plasticizing extrusion, strand cooling, drying and cutting, the PET flakes are processed into pellets material, Different color PET flakes will bring different color PET pellets. If necessary, the users can choose master batch to be pelletized together for change the color of final PET pellets.

Application of the PET pelletizing machine:

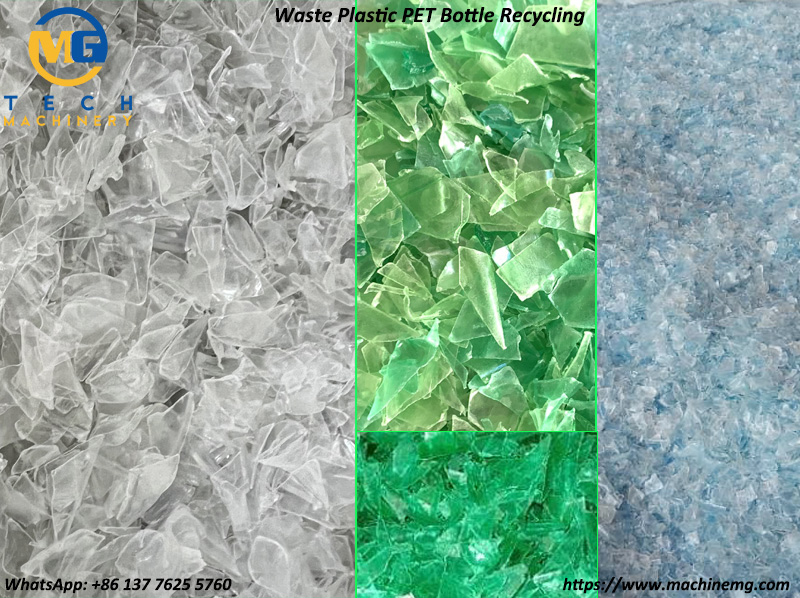

All recycled plastic PET flakes and scraps, for example, Cola bottle flakes, mineral water bottle flakes scraps, PET sheet flakes scraps, PET packing containers flakes, etc.

If such PET flakes or scraps are dirty, please choose the recycling washing lines to clean them before pelletizing.

Main units of the PET pelletizing machine

1, Parallel twin screw extruder

Powerful motor and reduction box are used for driving, ensure the smooth pelletizing production. Famous brands motors are used, for exmaple, WN, SIEMENS, etc. Motor speed control by inverter in the control cabinet.

Building block type screw structure is used for this extruder, and screw component connection to axes by involute spline, all screw components are high quality tool steel W6Mo5Cr4V2.

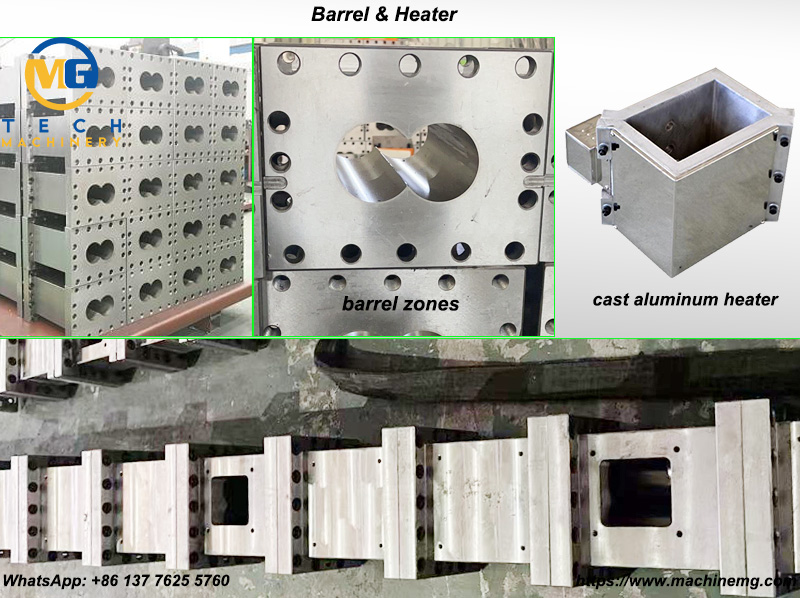

Barrel consists of different sections, which are made of 45 steel, and with bimetallic bushing inside for good durability. Some barrel sections are with opening for vacuum exhausting or natural degassing according to the pelletizing requirement on different materials.

Cast aluminum and copper heaters are used for the barrel heating, and use intelligent meters for temperature set and control.

Circular water cooling system is used for the barrel cooling, each barrel zones with independent solenoid valve.

Strong vacuum exhausting unit is equipped, and it's necessary for PET flakes pelletizing as usual.

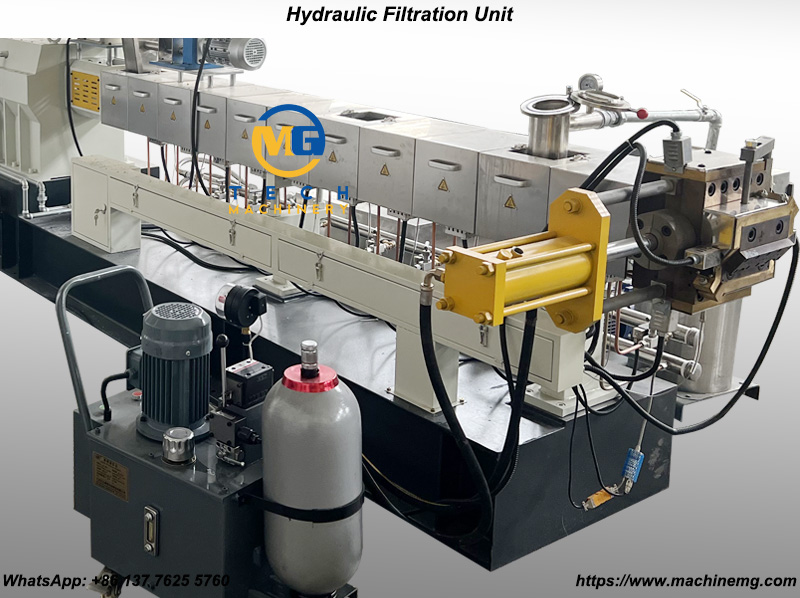

Two type of hydraulic filtration units are for choice, one is plate type double station filtration, the other one is column type double station filtration. By column type, the materials will not be cut off while changing the filtering screen, it's a non stop filtration unit.

2, Strand pelletizing system

1), Strand mold is made of 40Cr, with quenching treatment, hole diameter is 3-5mm. It will form the plasticized PET materials into noodle shape, and drop into the water tank for cooling.

2), Water cooling tank is made of stainless steel 304, anti rust and anti corrosion. When the PET noodles drop into the water tank at the beginning, the operator need to pull the materials to the gantry pellet cutter, and use the nylon rollers to press and lead the PET strand noodles in the water cooling tank, And it will work automatically once the PET noodles go into the pellet cutter.

3), Blowing dryer, It’s used to blow off the water from the PET noodles by a vortex air pump after the water tank, and collect and drainage the water by a stainless steel tray.

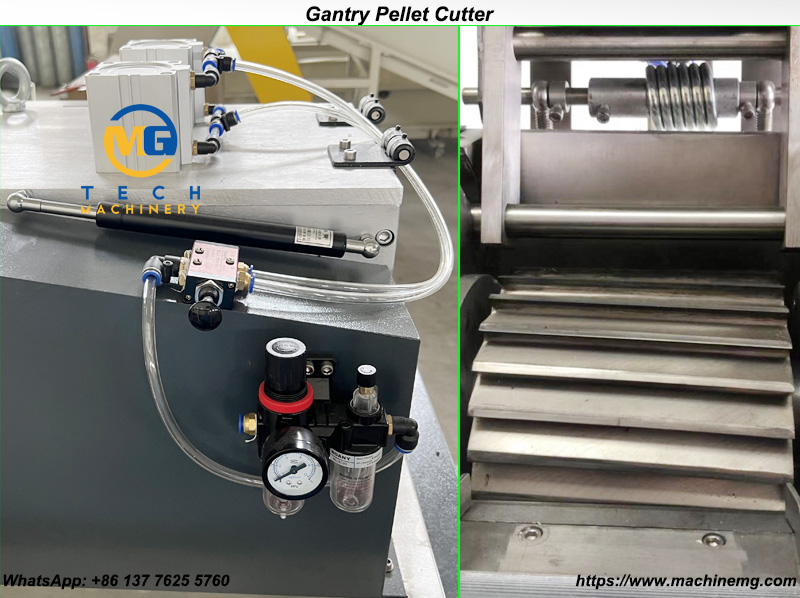

4), Gantry pellet cutter. The rotary blade has multi teeth structure, which is made of alloy steel.

Rubber roll is driven by pneumatic mechanism to compact the strand materials for cutting. Pellet length is adjustable by change of rotation speed through inverter.

5), vibration sieve.

It's used for classifying the PET pellets. The sieve and cover are made of stainless steel 304, two layers or three layers type for use.

As an optional unit in the PET pelletizing production line, the users can choose it for use or not according to requirements on pellet size.

6), cyclone system.

It's used to storage the pet pellets temporarily,

The pipeline and silo are made of stainless steel.

7), control cabinet

A centralized control system for the whole line. Good quality eletrical components and parts are used for the cabinet, for example, SIEMENS contactors, OMRON temperature meters, etc.

The users can set processing parameters on the panel, for example, temperature, feeding speed, host speed, etc.

Advantages of the PET Pelletizing machines:

1, high quality tool steel for screw components.

2, Special screw combination Euro-style rectangle barrel, reflux refrigeration channel optimized and disposed to makes smaller temperature difference.

3, Innovated design of heater-tightened style ensures high efficiency of heat transfer and high longevity of heater.

4, New-style project of parallel three-axis driving makes the convex axis, convey Chain, decelerate and torque get together, which keep it compact, and the key bearings are imported, soakage and spraying lubrication integrate smoothly technics, strengthening of tooth face, so they can ensure high torque, high precision and low noise.

5, powerful vacuum exhausting system for good degassing result, volatiles such as low molecular and moisture will be removed efficiently.

6, gantry pelletizer with alloy multi teeth blade and pneumatic compressing mechanism, smooth cutting.

7, good quality electrical components and parts for control cabinet, ensure the steady pelletizing working.

8,higher output and lower energy consumption.

9, less labor required.

10, quality certificate

Etc.

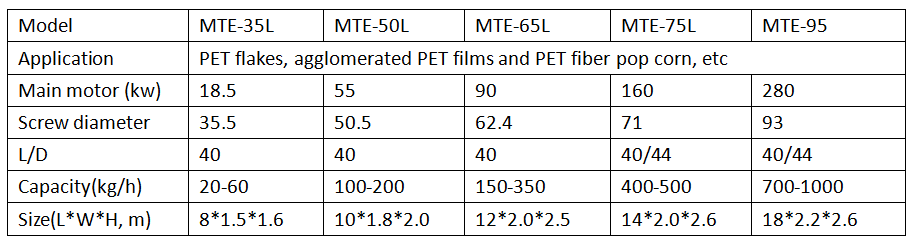

Models of PET pelletizing machines in MG Machinery company:

Why choose us?

1, full solution proposals, introduce the best pelletizing models according to your waste materials and requirement.

2, reasonbale machine flowchart and workshop layout according to your workshop area.

3, best quotation for high quality pet pelletizing production lines.

4, skilled and experienced workers for the machine manufacturing.

5, shipment on time.

6, careful machine loading and fixing work in container.

7, dispatch engineer for after sale service in your company on time

8, training for machine and operation.

9, technology support all lifetime of the machine.

10, cost price for machines parts if replancement is necessary.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007, for example, Japan, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Geogia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.