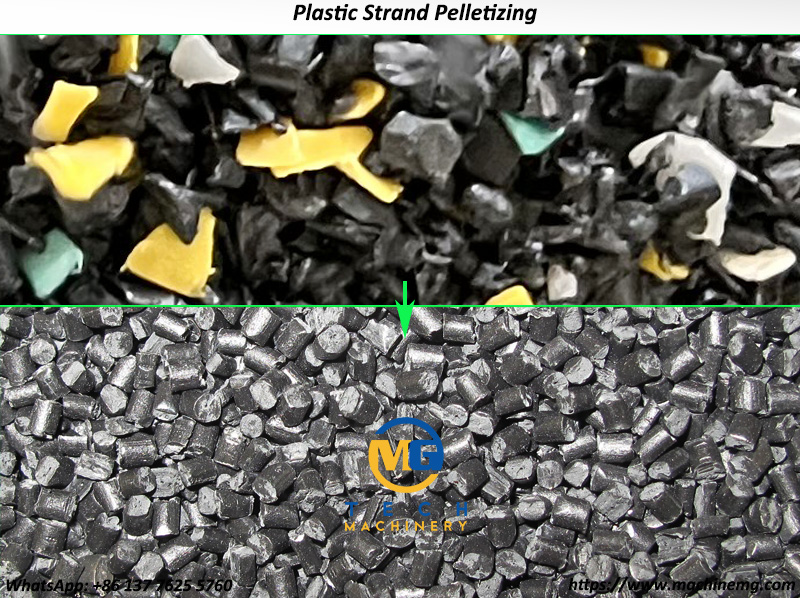

The plastic strand pelletizer line is mainly used to make pellets from the rigid plastic flakes, scraps, particles, squeezed PE PP films and bags. The pelletizing line is double stage type, adopts strand mold to make noodle shape plastic for cooling in water tank, and gantry pelletizer for cutting the noodle plastic into pellets.

Application of the plastic strand pelletizer:

1, kinds of plastic flakes, for example, PE, PP, ABS, PS, PC, etc.

2, kinds of crushed plastic particles from plastic lumps, containers, pipes, etc.

3, squeezer PE PP plastic films and bags.

4, unqualified plastic pellets for re pelletizing.

The plastic plastic pelletizer machine can be used after the rigid plastic recycling washing lines, or separate use in plastic recycling plants, plastic products manufacturing factories, etc.

Consist of the double stage plastic strand pelletizer line:

1, plastic materials loader: it's used to load the plastic into the hopper of pelletizing extruder from ground, the users can choose belt conveyor or screw loader as usual.

2, two sets of single screw extruders

The extruders are used to plasticize and exhaust the materials well, for high quality pellets production.

Alloy barrel and screws, cast aluminum heater with air cooling.

Powerful drive system with good quality motor, reducer and inverter.

Vacuum degassing system for good exhausting result.

3, hydraulic screen changers:

Each extruder with one hydraulic screen change for good filtration result to filter out the impurities, therefore, it will purify the plastic to improve the pellet quality.

As usual, plate type double position screen changer is the standard configuration for our plastic pelletizing lines, but we have pillar type double position screen changers for your choice.

4, strand mold:

By working with the extruder, to make noodle shape plastic for cooling and cutting.

5, water cooling tank:

Cool the strand materials for good cutting result.

It's made of stainless steel, anti rust, anti corrosion.

With water level control, avoid water overflowing.

6, gantry pelletizer:

Cut the strand materials into pellets, length of the pellets is adjustable through the speed control of the motor.

7, cyclone system:

Blow the pellets into silo for temporary storage, for easy package.

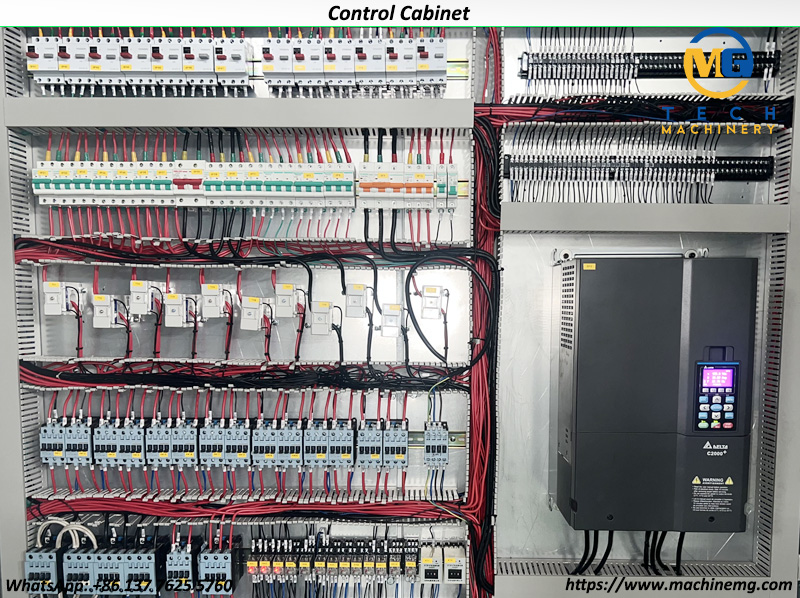

8, centralized control cabinet:

The control cabinet is used to control the working of the whole double stage plastic strand pelletzer line.

Good quality electrical components and parts are chosen for installation, for example, SIEMENS contact, TENGEN air switch, OMRON temperature meter, ABB or Delta inverters, etc.

Is the plastic pelletizer what are you looking for? please send an enquiry to us for official quotation of the plastic strand pelletizer machine.

Advantage of double stage plastic strand pelletizer line in MG Machinery:

1, multipurpose for different plastic flakes and agglomerated materials, such as PE, PP, PS, ABS, PC, PET, etc.

2, special screw structure design for good plasticizing result.

3, vacuum degassing system for good exhausting.

4, alloy barrel and screw with nitrogen procession, wearable, long lifetime.

5, hard teeth reducer, big torque.

6, good quality motors, reducer, inverter and electrical components.

7, cast aluminum heater, fast heating.

8, OMRON temperature meter, precise control.

9, hydraulic screen changer with two filter position for alternative use.

10, gantry pelletizer with alloy blades, smooth cutting.

11, easy operation and maintenance.

12, low running cost for high output.

13, high automation, labor saving.

14, strong machine structure.

15, quality certificate.

etc.

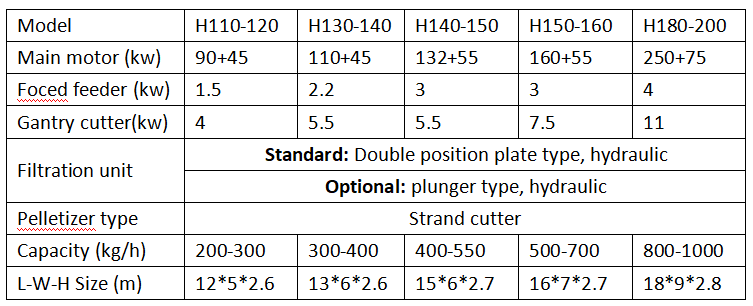

Models of double stage plastic strand pelletizer machine in MG Machinery:

Other models for different capacity are availabel, please contact us freely.

Why choose us?

1, we can provide the most suitable pelletizer proposals based on your detailed requirement.

2, machine flowchart and workshop layout design according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007, for example, Japan, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Geogia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.