One stage plastic strand pelletizer line, including vertical feeder and side forced feeder, uses strand pelletizing method for all purpose plastic recycling pelletizing production. The plsatic pelletizer design provides a good recycling solution for the users on less invest but more usage.

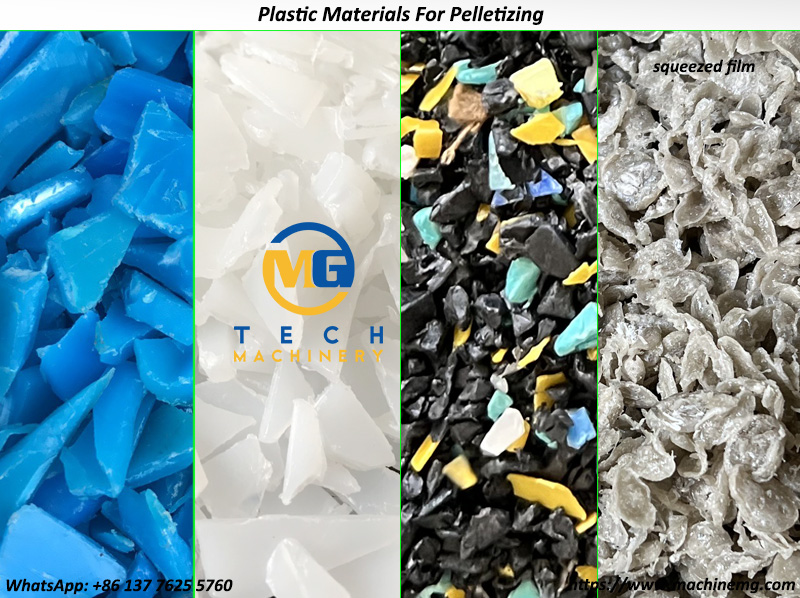

Application of the strand pelletizer line with two feeders:

1, kinds of plastic PE PP films, the users just need a crusher to crush the big films into small pieces, which can be pelletized directly.

2, crushed or shredded PP bags materials from the jumbo bags and woven bags.

3, squeezed or agglomerated waste plastic films and bags.

4, different plastic flakes, crushed particles, and unqualified pellets.

etc.

Consist of the one stage plastic strand pelletizer line for all purpose pelletizing:

1, side forced feeder: It uses the screw for pressing and feeding the soft and loose plastic mateials into the extruder barrel.

2, vertical feeder: It is used to feed the rigid plastic flakse, particles and powder into the extruder for pelletizer.

3, single screw extruder:

To get the good plasticizing result, the screw structure is designed and manufactured according to plastic features.

Alloy 38CrMoAlA is used to make the barrel and screw, durability, for long time pelletizing processing.

And a strong vacuum degassing system with double sucking opening is equipped on the barrel, to ensure the good exhausting result especially for the plastic materials with high mositure.

Powerful driving system with good quality motor, inverter and reducer, to ensure the smooth extruding and plasticizing.

For our plastic pelletizer machines, the motor are with famous brands in China, for exmaple, WN, SIEMENS, JIAMUSI, etc.

Reduces are usually from GUOMAO, and the inverters like Delta, ABB, Invt, etc.

4, hydraulic screen changer.

The standard one is double position plate type for smaller and middle models of the plastic strand pelletizers, and four position plate type is used for big pelletizer models.

As a optional unit, we can also provide the plunger type for your choice. It has double column cylinder design with large filter area, stronger pressure resistance, and non stop for net change.

5, strand mould: it is made of 40Cr steel with quenching treatment. Hole diameter is usualy 3-5mm, and the hole quantity is made according to the capacity of the plastic strand pelletizer lines.

6, water cooling tank: the tank is made of stainless steel, anti rust and anti corrosion. Nylon rollers are used for leading the plastic noodles out from the strand mould, for good cooling in the water tank.

7, blower dryer: It's a vortex air pump provides strong wind to blow off the water from the plastic noodles, a stainless steel tray is for water collection and drainage.

8, pellet cutter: Gantry cutter is used for the plastic pelletizer, the length of the pellets is adjustable through a inverter to control the rotation speed of cutter.

9, cyclone silo:

It's a cyclone system for conveying the pellets into the silo, temporary storage for packages.

The silo and pipe are made of stailess steel,

10, centralized control cabinet.

The user can set the different processing parameter on the panel, and control the operation of the whole plastic strand pelletizer line easily.

Good quality electrical components and parts are used to ensure the steady pelletizing work, well grounded, more safety.

Advantage of the one stage plastic strand pelletizer machine in MG Machinery:

1, all purpose pelletizing for kinds of waste plastic flakes, particles, films and bags.

2, barrel and screw are made from 38CrMoAlA steel with nitrogen treatment, long lifetime.

3, plasticizing and degassing well.

4, good quality motors, reducer and electrical components, steady work.

5, centralized control system for operation of whole line, more convenience, easy operation.

6, lower maintenance cost,

7,strong machine structure.

8, quality certificate,

etc.

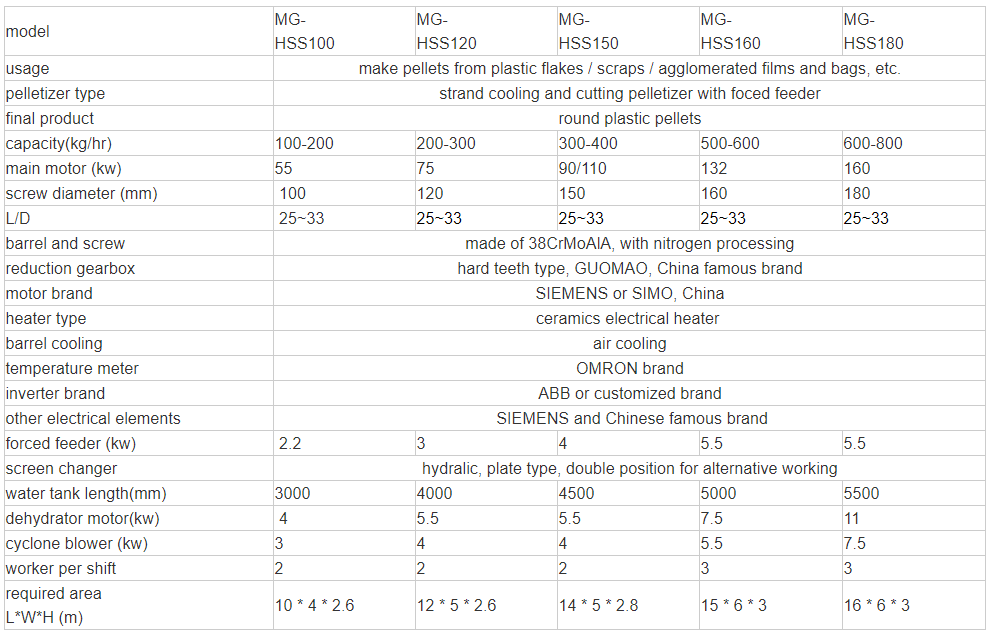

Models of one stage plastic strand pelletizer machine with two feeder:

Why choose us?

1, full solution proposals and pelletizer choice suggestion according to your waste materials.

2, machine flowchart and workshop layout design free.

3, high machine manufacturing technics.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch skilled engineers for after sale service in your company on time

9, training for machine and operation.

10, technology support all lifetime of the pelletizer machines

11, supply machine parts at cost price if replacement is necessary

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007, for example, Japan, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Geogia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.