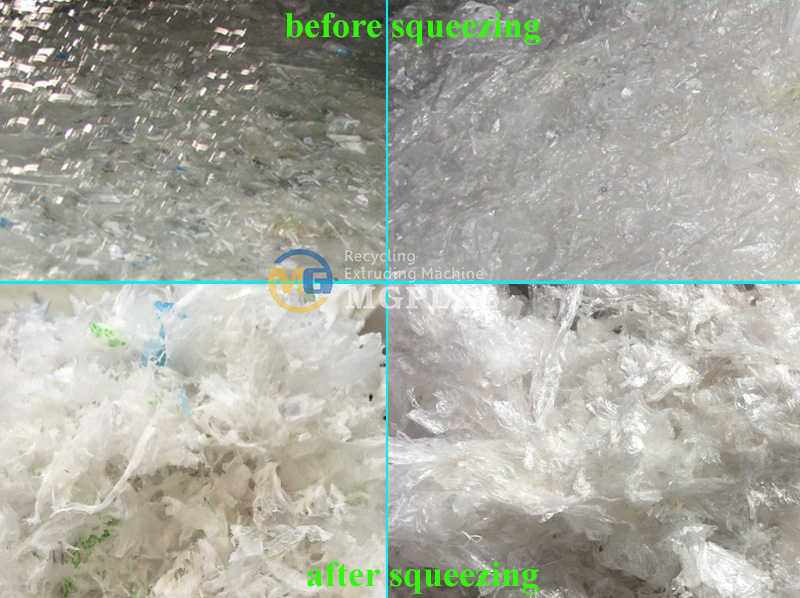

The plastic film screw press dryer is used for dehydrating the waste wet or washed PP PE plastic film, its' dehydration rate is over 90%, and the dryer machine will not change the performance and properties of the plastic films and bags after squeezing recycling.

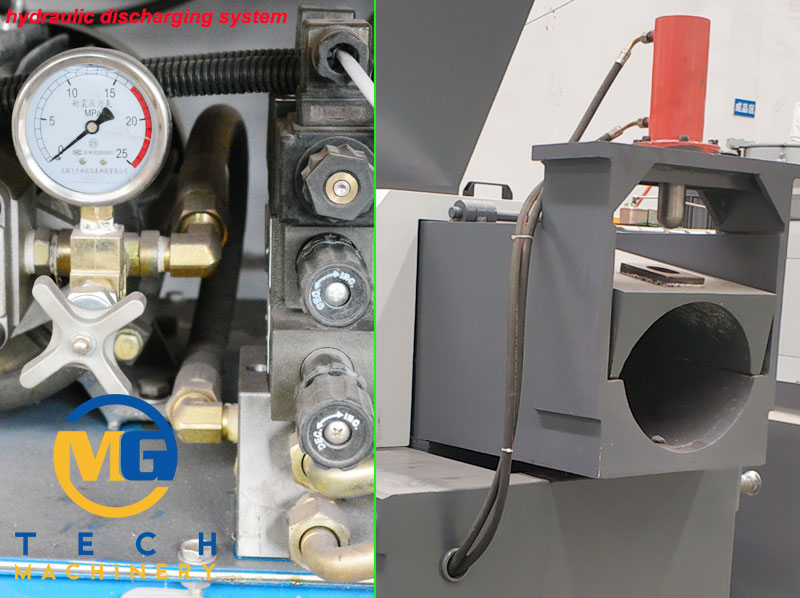

Film drying way: by hydraulic pressure system and screw squeezing in the alloy barrel to squeeze out the material from the film materials, and drain the water from the holes of the barrel.

Application: the screw press dryer can be used for squeezing kinds of waste plastic films and bags, for example, agricultural films, package films, agricultural films, plastic shop bags, fresh keeping film bags, garbage bags, hand bags and vest bags, etc.

Mateiral size for squeezing drying: all the PE PP waste plastic film and bags should be crushed firsty by a crusher or shredder machine. The screw press squeezing dryers have very good results to the plastic washing recycling lines for the PE PP films and bags.

Power consumption: compared with the centrifugal dewatering machine, the plastic film screw press dryer can save 60-70% power for same capacity requirement but with better dehydration rate.

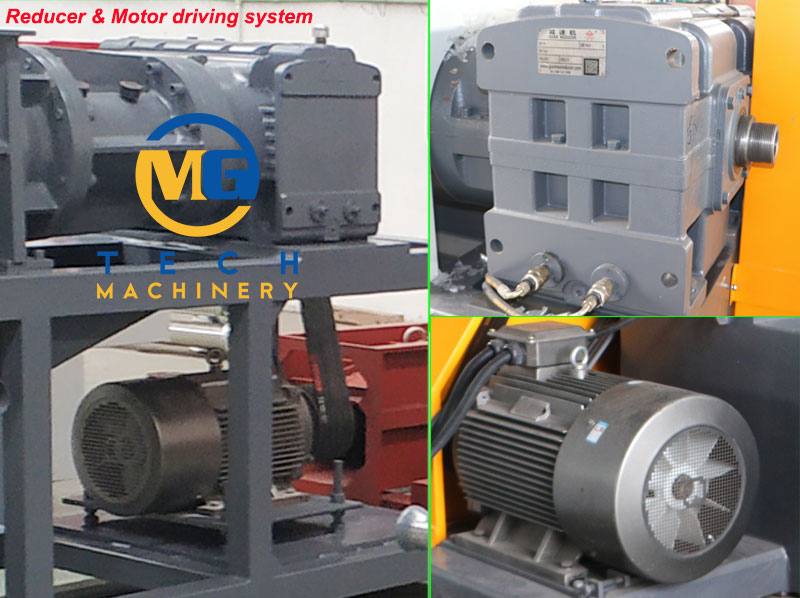

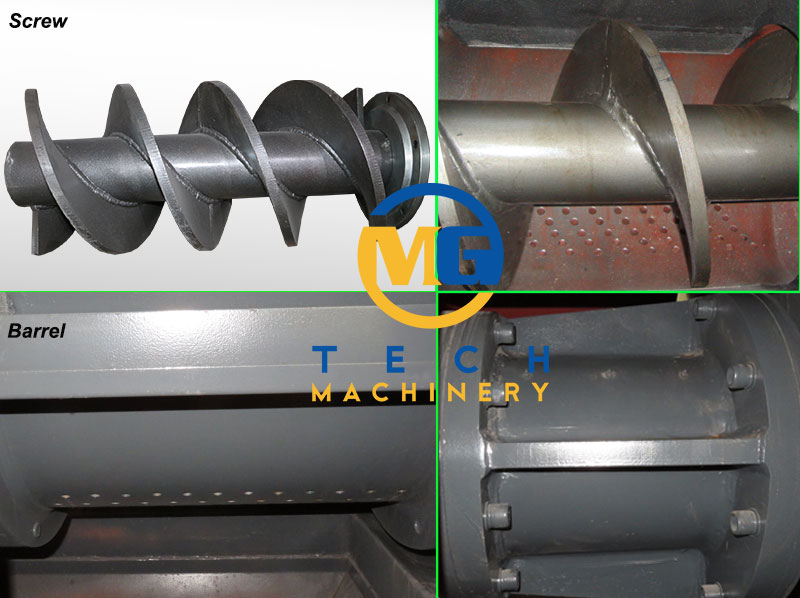

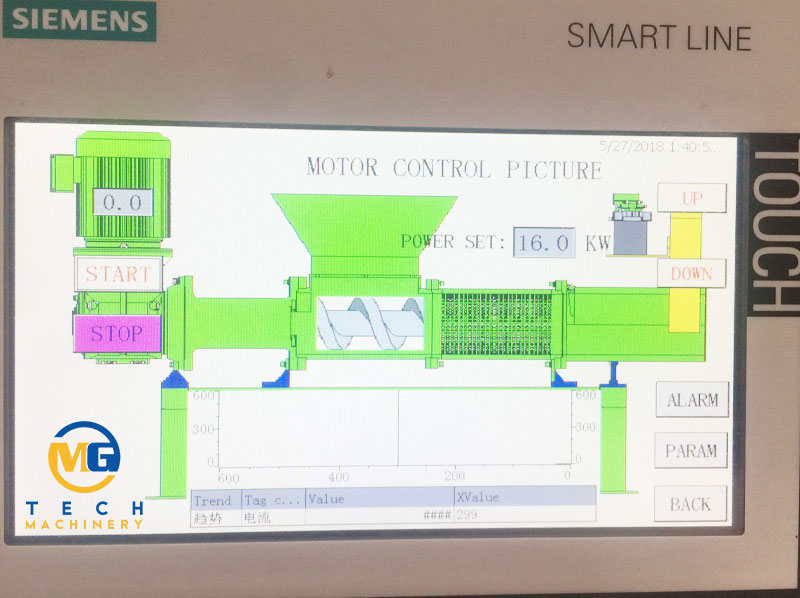

Consists of : One plastic film screw press dryer consists of main motor, horizontal reducer, barrel, screw, water discharging unit, hydraulic system, control cabinet and strong machine frame, etc.

1, powerful driving system

2, alloy barrel and screw

3, Hydraulic pressure control system: Discharge the film by pressure control.

4, Centralized control system: PLC touch control system or PID control system for your choice:

5, Dewatering effect by the screw squeezing dryer machine:

The plastic film screw press dryers can be used in the plastic film crushing washing line or independently in the waste plastic recycling plants. After processing by the forced screw pressing and squeezing, the electrical heating dryer is not necessary again.

It's the new developed and most efficient machine for dewatering in the waste plastic film recycling industry.

Please send your enquiry, our team will make quick response to work with you.

Advantages of plastic film screw press dryer in MG Machinery:

1, high dewatering rate, final moisture can be 8-12%.

2, low power consumption for big capacity.

3, horizontal reducer, big torque for screw pressing.

4, 38CrMoAlA barrel and screw, wear resistant, long lifetime.

5, PLC control, easy operation for parameter set.

6, low rotation speed, lower noise.

7, heavy structure, steady working.

8, auto material discharging, less labor required

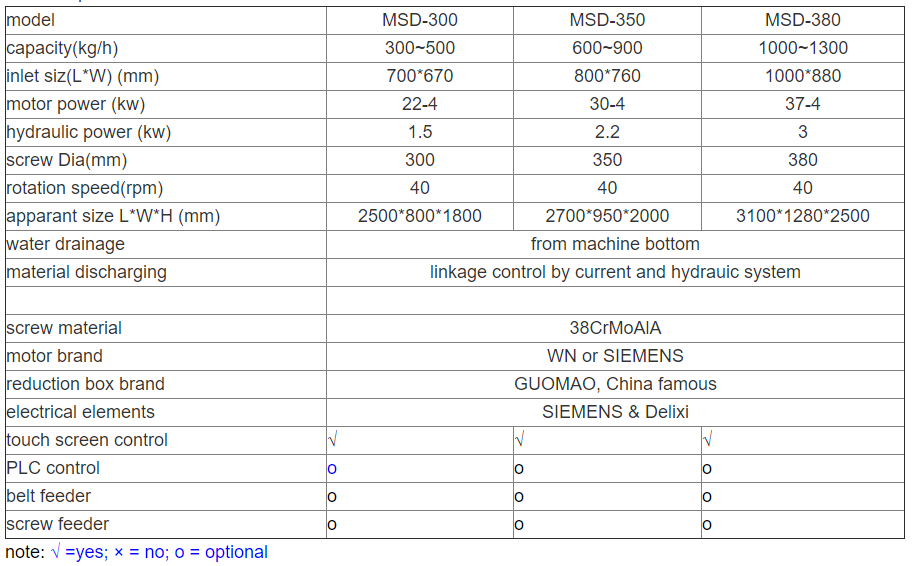

Models of plastic film screw press dryer in MG Machinery:

What we can do for you in the cooperation?

1, full solution proposal design on machines.

2, correct machine model suggestion.

3, factory price for cooperation.

4, skilled and experienced workers for machine manufacturing and after sale service.

5, delivery on time.

6, 14 months guarantee for the screw press and squeezing dryer.

7, cost price for parts if necessary for change.

etc.

Our plastic recycling machines have been exported to Japan, Malaysia, Thailand, Vietnam, India, Nepal, Iran, UAE, Saudi Arabia, Ukraine, Russia, Geogia, Serbia, Ghana, Kenya, Togo, Malaysia, USA, Mexico, Chile, Colombia, Ecuador, Argentina, etc.