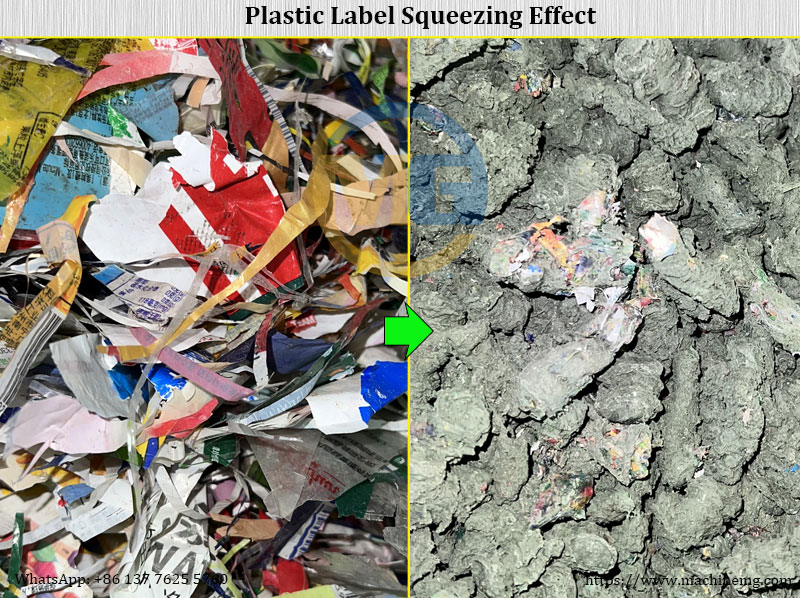

Plastic Squeezer Machine for Waste Plastic Label Recycling

The Plastic Squeezer Machine is a state-of-the-art solution designed to streamline the recycling process for waste plastic labels, such as those made from PET, PP, PE and PVC materials. This innovative machine is engineered to compress and squeeze plastic labels, significantly removing excess water moisture, reducing their volume and making them easier to handle, store, and transport for further processing.

Functions of the plastic label squeezer machine:

1. Volume Reduction: Compacts bulky plastic label waste into dense, manageable pieces.

2. Moisture and Adhesive Removal: Squeezes out water and separates adhesives, improving the quality of recycled material.

3. Pre-Treatment for Recycling: Prepares label waste for further processing, such as shredding, pelletizing, or extrusion.

4. Waste Management: Helps reduce environmental impact by enabling efficient recycling of plastic label waste.

Applications:

1, Recycling facilities

2, Plastic manufacturing plants

3, Waste management companies

4, Sustainable packaging industries

Benefits:

1, remove the high moisture from the waste label materials, ensure high processing quality on further recycling machines.

2, Reduces storage and transportation costs by minimizing label volume.

3, Enhances recycling efficiency and supports eco-friendly practices.

4, Contributes to a circular economy by preparing plastic labels for reprocessing.

The Plastic Squeezer Machine is the ultimate solution for businesses looking to improve their waste plastic label recycling processes while promoting sustainability and cost-effectiveness.

Key Features of the plastic squeezer machine in label recycling field:

1, High Compression Efficiency: Reduces the volume of plastic label waste significantly, making storage and transportation more cost-effective.

2, Dewatering Function: Effectively removes moisture from label waste, ensuring clean and dry material for pelletizing or extrusion.

3, Durable Construction: Built with robust materials to withstand the challenges of processing adhesive and thin film labels.

4, Energy-Saving Design: Operates with low energy consumption while maintaining high productivity.

5, User-Friendly Operation: Easy to operate and maintain, with adjustable settings for different types of label materials.

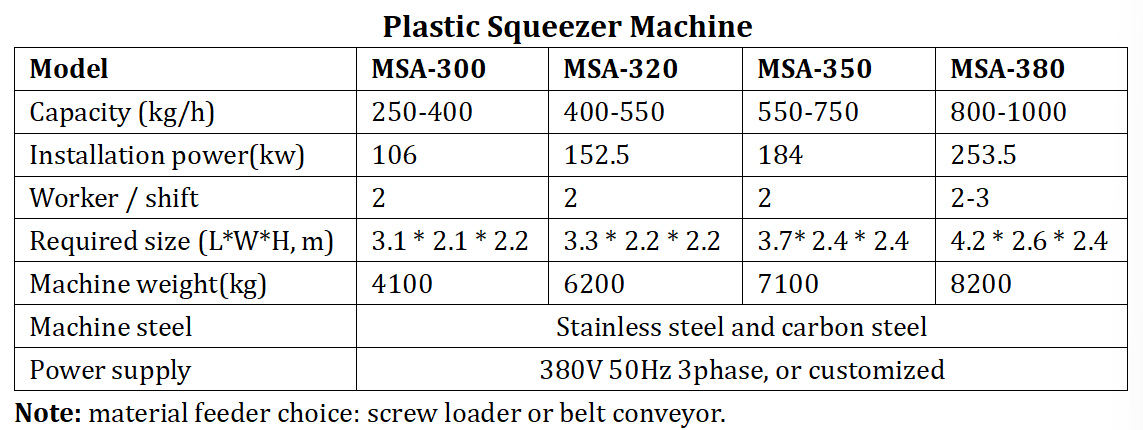

Models of plastic squeezer machines in MG machinery company:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries in the last 10 years, for example, Japan, South Korea, Vietnam, Indonesia, Thailand, Malaysia, India, Sri Lanka, Iran, UAE, Saudi Arabia, Israel, Iraq, Russia, Ukraine, Serbia, Georgia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, Brazil, etc.