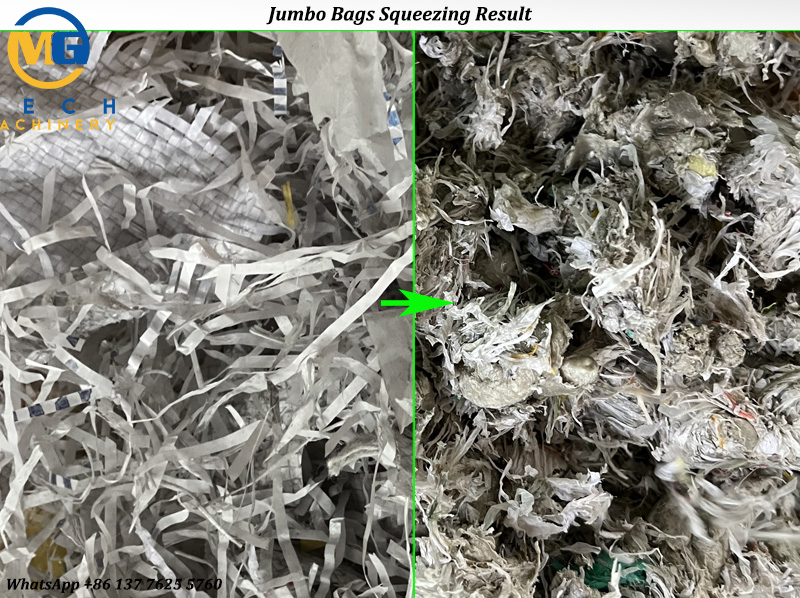

Plastic film squeezer dryer machine is used to dry the wet soft plastic materials by screw pressing and squeezing for high dewatering rate and less material volume obtained. It is suitable for kinds of waste plastic films, pp jumbo bag and plastic labels even mixing with some plastic flakes or caps, etc.

Due to the good performance on dewatering for plastic film and bags, The plastic film squeezer dryer machine are used more and more in the waste plastic film and bag recycling plants, as well as in the plastic oil refining plants. It's an ideal machine for drying wet film and bag materials in the waste plastic film recycling plants now.

By the plastic film squeezer dryer machine, the final moisture of plastic film or bags can be less the 5%, and the material volume can be reduced 60% at least. It’s more convenient for reuse, storage and transportation.

Main parts of plastic film squeezer dryer machine

1, Motor and reducer

Powerful motor and reducer are installed on the plastic film squeezer dryer for steady squeezing and granulating work famous brandsmotors and reducer are used, for example, WN, SIEMENS China, JIAMUSI motors, and GUOMAO reducers.

2, Barrel and screw

The barrel and screw are made of alloy steel, with nitriding treatement on the surface, more hardness, durability.

Screw has special design to ensure the smooth feeding of films and bags materials.

Barrel with more thickness, and holes on the wall for drainage quickly while the pressing and squeezing to the films or bags, so that

to get the high dewatering result.

3, Heater system

For small and middle models of plastic film squeezer dryer machines, the cast aluminum heaters are used, and for big squeezer machine,

the electromagnetic heaters is necessary. heating temperature is controlled by OMR meters for more precision.

4, cooling system.

Water cooling system is equipped for reducer and mold head cooling.

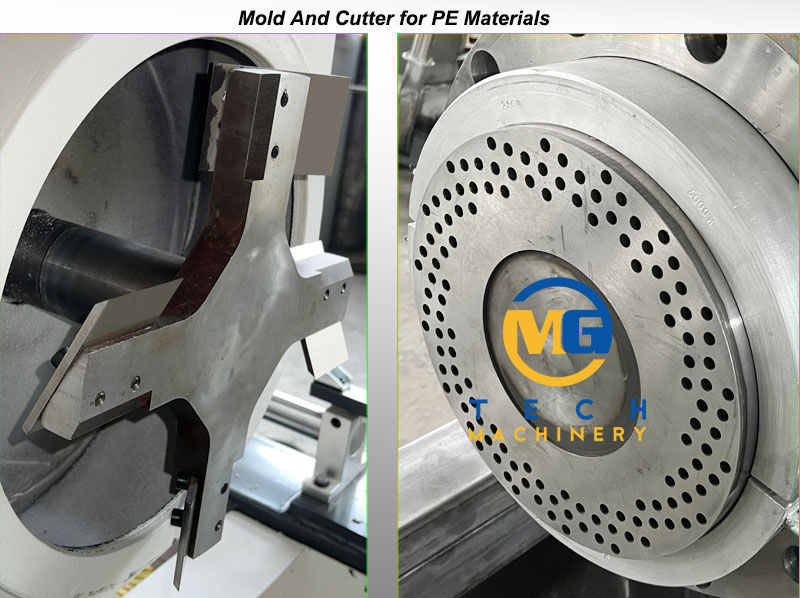

5, granulating system.

A perforated mold is installed on the head of the plastic suqeezer machine, and a cutter with 2pcs or 4 pcs blades are matched with the mold for pelletizing. While the plastic materials are squeezed out from the barrel and mold, the cutter cut the strands on the die face immediately into the pellet shape or agglomerated materials, which will drop into the transit silo and are blown into sysclone silo.

For PE and PP materials, the perforated molds are different.

6, control cabinet.

The control cabinet is used for the centralized control of the plastic film squeezer dryer machine. Good quality electrical components

and parts are used for making the cabinet, for example, SIEMENS contactor, ORMRON temperature meter, Delta or ABB inverters, etc.

It's very easy for the users to set required technical parameters on the panel, for example, rotation speed, temperature value, etc.

The plastic film squeezer dryer machines have more application for kinds of soft waste plastic materials.

In the waste plastic films and bags recycling factories, the plastic film squeezer dryer machine can replace the centrifugal dewatering machine and electrical dryer of washing line, for more, the compactor machine of plastic pelletizer line is not a necessary unit then. Based on the real using feedback, the plastic squeezer film squeezer dryer machine can save 30% power consumption at least for same capacity requests of plastic washing line and plastic pelletizing line.

How to feed the materials into the plastic film squeezer dryer machine?

The users can choose the belt conveyor or screw loader to standby the plastic squeezer machine, and it will help to convey the

materials into the squeezer from the ground.

Screw loader is more suitable for the materials with high moisture, and the belt conveyor is usualy for the material with less water

content.

Advantage of plastic film squeezer dryer machine in MG Machinery:

1, both dewatering and agglomerating functions by one time processing.

2, high dewatering rate, final moisture less than 5%.

3, good semi-plasticizing, no effect to material quality in the after process like pelletizing.

4, wide usage for kinds of plastic films and bags.

5, horizontal reducer, big torque for screw pressing squeezing.

6, alloy steel for barrel and screw, wear resistant, long lifetime.

7, PLC control, easy operation for parameter set by different materials conditions.

8, low rotation speed, lower noise.

9, heavy structure, steady working.

10, cyclone system for materials discharging, less labor required

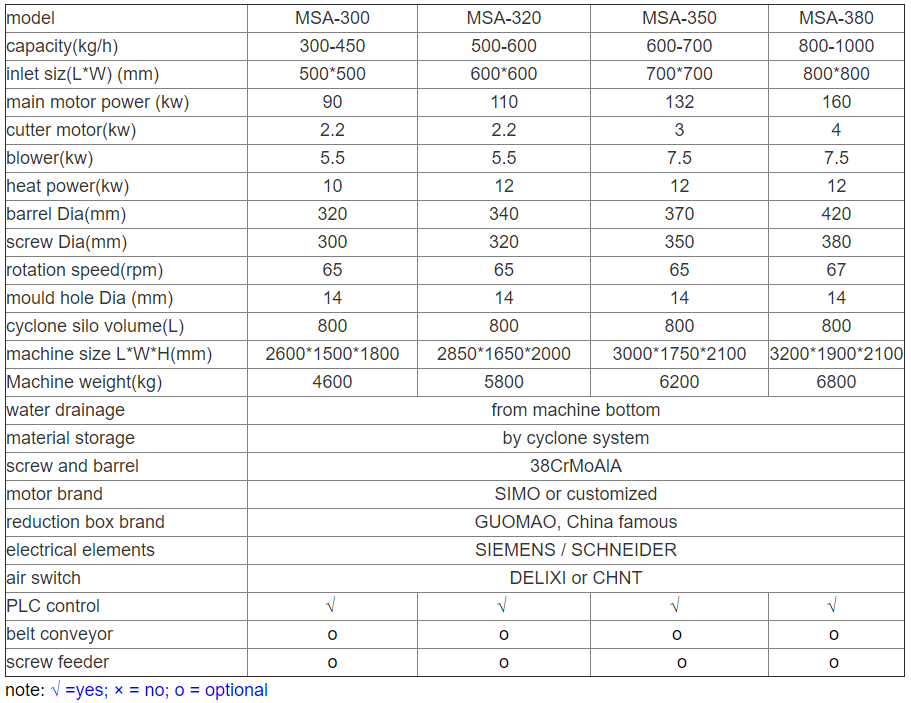

Models of plastic film squeezer dryer machine:

Why choose us?

1, we can provide the most suitable solution proposals according to your waste materials conditions and requirement.

2, professional design for machine flowchart and workshop layout according to your workshop area.

3, skilled and experienced workers for the machine manufacturing.

4, good testing for the machines before shipment.

5, shipment on time.

7, careful machine loading and fixing work in container.

8, dispatch engineer for after sale service in your company on time

9, training for machine and operation.

10, technology support.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007, for example, Japan, Vietnam, Indonesia Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Geogia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.