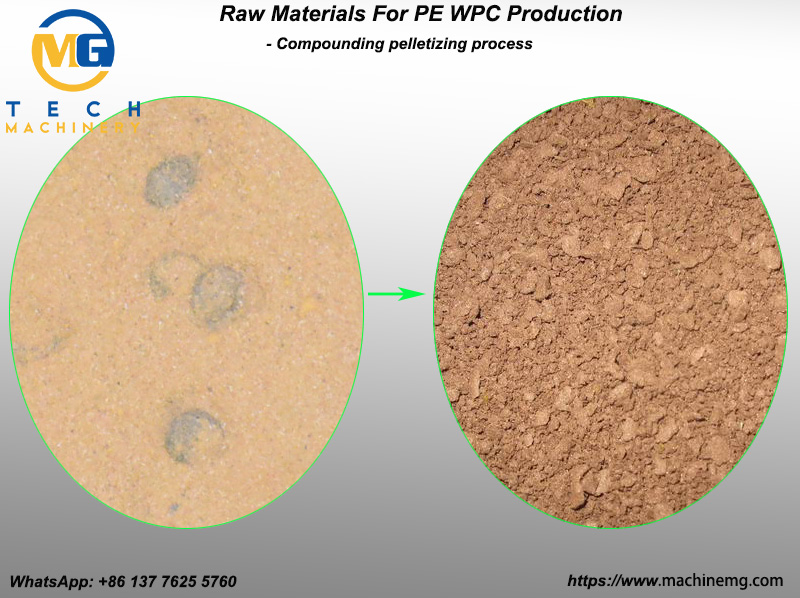

WPC granulating line is used for compounding wood plastic composite materials with good degassing and color mixing for WPC profiles production. The granulating extruder works by melting the plastic and mixing it with the wood flour and other additives, then extruding the mixture through a die to create the granules as traditional granulating way. But it is proven that the compounded WPC materials have good performance also from the exttruder head without pellet mold, And it's an efficient way to get higher output from the same WPC granulating line, which are developed by MG technician team in 2011. It's the popular granulating way for all PE WPC or PP WPC in the whole WPC industry after that time.

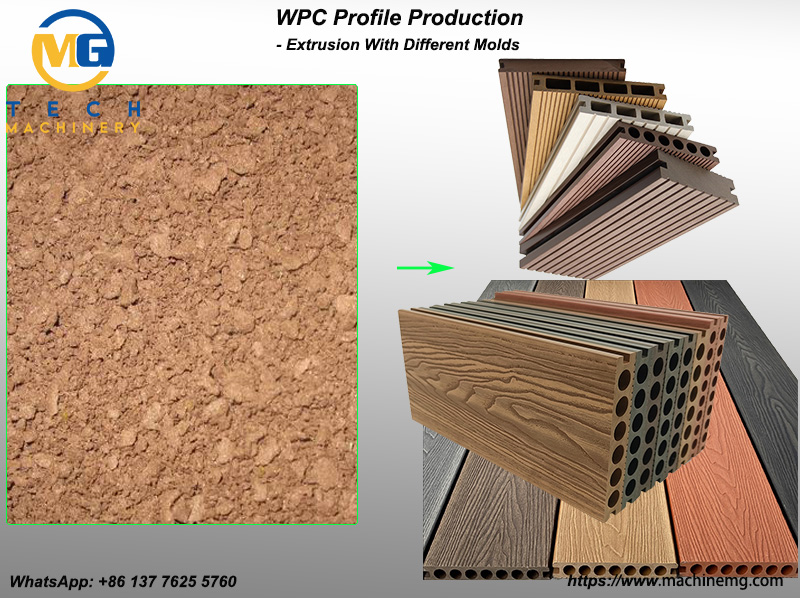

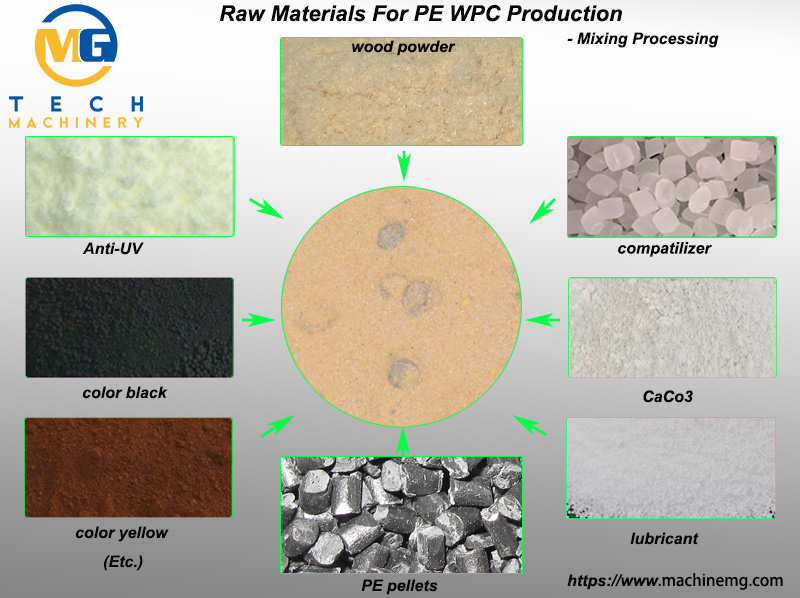

WPC is the material made by combining wood fibers or sawdust with plastic materials such as polyethylene, polypropylene or PVC. And the WPC granulating lines are widely used for wpc materials preparation in the manufacturing of WPC decking, fencing, furniture, door, door frame, corrugated roof tile and other WPC profiles.

A typical and efficient WPC granulating line consists of the following units:

1.Feeding system.

This system is used to feed the raw materials into the granulating line. As usualy, the raw materials of WPC usage should be mixed firstly by a high speed mixer machine or heating cooling mixer unit.

2.Extruder type

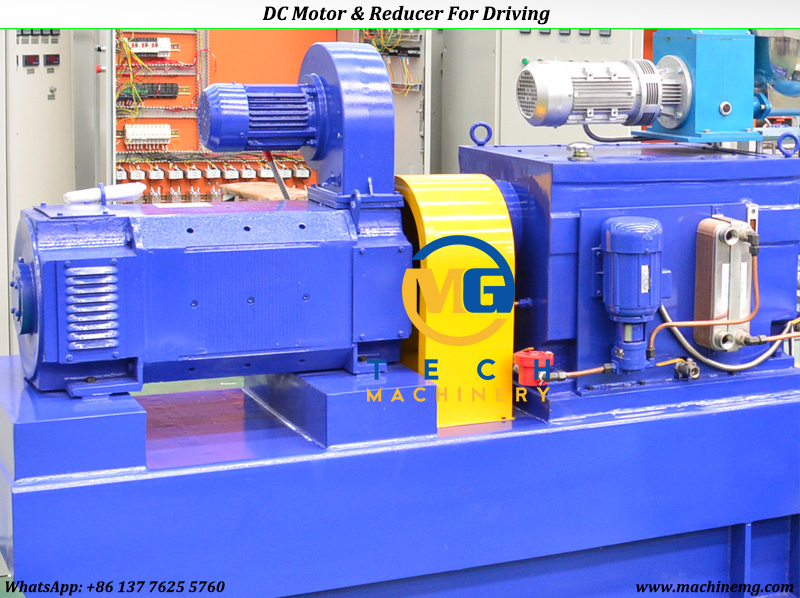

A parallel twin-screw extruder is used to mix and melt the mixed WPC raw materials. The extruder has a heating system that heats and melts the plastic material and additives, while the wood fibers and other filling materials are mixed in. For the driving system, famous brands of motor and reducers are used, and DC or AC motors are for optional.

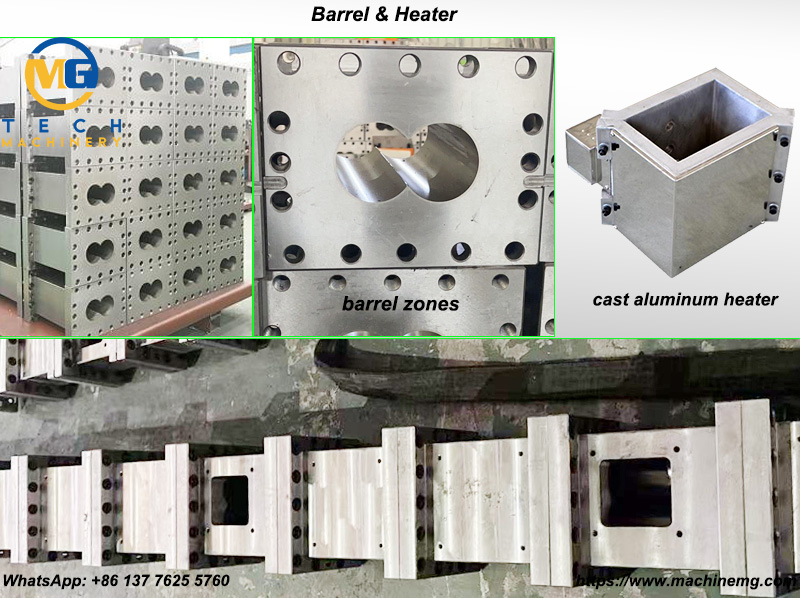

Barrels are made of quenched 45# steel with α101 bimetallic bushing inside. The barrel zones are arranged in block type combination, containing the water cooling channel. And cast aluminum heaters and cast copper heaters are used for barrel heating.

The screws are of modular design,It is also named as building block type screw structure.

The screw element and the mandrel are involute connection, high strength and bearing load, convenient disassembly and assembly combination.

3.Cooling system for extruder

Water circular cooling system is used for the barrel to control the temperature with the intelligent temperature meters. Solenoid valves are installed on the pipelines of each heating zone for controlling the water quantity easily.

4, vacuum degassing system.

It's an optional unit for WPC pelletizing process.

5, cyclone system with crusher:

The melted and compounded wpc materials come out from the extruder head, and drop into the transit silo of the cyclone system directly. Under the transit silo, a crusher is usually used for grinding the WPC materials into small particles or scraps, which will bring the more efficiency on WPC profile extrusion. After the grinding by WPC crusher, the WPC materials will be sent into the storage silo for temporary storage, waiting for the package and transportation.

While the whole conveying, it can also do some cooling for the WPC materials.

6, control system.

Centralized control cabinet is made for easy operation of the whole WPC granulating line. The operators can do the set and adjustment of technical parameter on the panel directly, for example, motor rotation speed, temperature values, etc. Good quality electrical parts are used for the control system, such as SIEMENS contactors, OMRON meters, DELTA inverter, etc.

Overall, a WPC granulating line is an efficient and cost-effective way to produce high quality WPC compounded materials for making various WPC profiles in the WPC industrial, such as extrusion of WPC decking, WPC fencing, WPC wall cladding, WPC pergola and WPC door. Even for WPC co extrusion production, the granulated materials are also very important for the core layer.

Auxiliary machine to the WPC granulating line:

Before granulating the WPC raw materials, It is necessary to mix the plastic, wood flour and additives by a special mixer machine. As usual, the users can choose high speed mixer machine or heating cooling mixer group for the WPC materials mixing.

Advantages of PE PP WPC granulating line in MG Machinery:

1, good performance on plasticizing, exhausting and compounding.

2, screw is the building block model, all screw elements can be replaced easily.

3, screw elements is made from W6M05Cr4V2 steel, wearable, long lifetime.

4, Barrel with alloy sleeve a-101 for screw protection, hardness HRC58-64.

5, cast copper type and cast aluminum heaters for even heating on the barrels.

6, accurate temperature control by RKC or OMRON temperature meters.

7, Main motor could be AC type with inverter, or DC type with speed regulator.

8, High torque gearbox.

9, streamlined feeder and hopper for smooth material feeding and easy cleaning.

10, good lubricating oil cooling system and soft water circular cooling system.

11, interlock control system for lubricator and host, feeder and host, pressure and host, current and host. For machine protection.

12, opening head design for good pressure releasing and higher capacity.

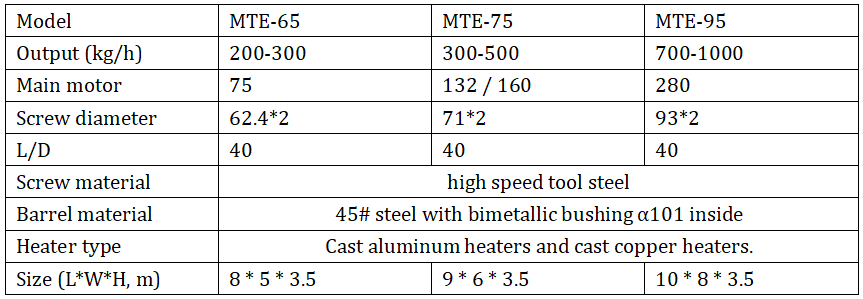

Models of WPC granulating line in MG Machinery:

Why choose us?

1, provide the whole solution for WPC production. Even from waste plastic recycled if required.

2, professional designs of WPC machine flowchart and workshop layout quickly

3, best quotation for high quality WPC machines from China.

4, high manufacturing technics and strict quality control for WPC machines.

5, complete machine testing well before shipment.

6, shipment on time. And we can help on ship booking, container loading with good fastening in factory

7, dispatch engineer for after sale service on time.

8, training for machine operation in your company.

9, technology support all lifetime.

10, cost price for quick-wearing parts all lifetime.

etc.

Our WPC extrusion machines and plastic recycling machines have been exported to many countries since 2007, for example, Japan, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Georgia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.