Die face hot cutting WPC granulation line is used to prepare 'ready to use' raw materials from wood powder, plastic hdpe or pp and processing additives for extrusion production of wood plastic composite wpc profiles.

This type wpc granulation line with multiple hole mould at the machine head for granule cutting, it's can produce the round wpc pellets.

After Processed by the wpc granulation line, the compounded wpc materials can be used to produce kinds of wpc products, for example, WPC decking, wpc flooring, wpc doors, wpc boards, wpc door frame, wpc wall cladding, wpc moulding strips, wpc panels, wpc pallet, corrugated wpc roof tile, etc.

In wood plastic composite WPC production, Especially for PE WPC and PP WPC, It is necessary to compound the materials well before end extrusion for good quality WPC profiles.

With the special parallel twin screw designs of wpc granulation line, the wpc materials can be exhausted well, and the different materials ingredients can be plasticized and mixed even. Therefore, It can ensure the final wpc profiles with uniform color and smooth section texture.

Advantages of die face hot cutting PE WPC pelletizing granulating line in MG Machinery:

1, closed head with multiple hole mould for round wpc granules production.

2, good performance on plasticizing, exhausting and compounding.

3, screw is the building block model, all screw elements can be replaced easily.

4, screw elements is made from W6M05Cr4V2 steel, wearable, long lifetime.

5, Barrel with alloy sleeve(A-101) for screw protection, hardness HRC58-64.

6, cast copper type and cast aluminum heaters for even heating on the barrels.

7, accurate temperature control by RKC or OMRON temperature meters.

8, Main motor could be AC type with inverter, or DC type with speed regulator.

9, High torque gearbox.

10, streamlined feeder and hopper for smooth material feeding and easy cleaning.

11, good lubricating oil cooling system and soft water circular cooling system.

12, interlock control system for lubricator and host, feeder and host, pressure and host, current and host. For machine protection.

13, opening head design for good pressure releasing and higher capacity.

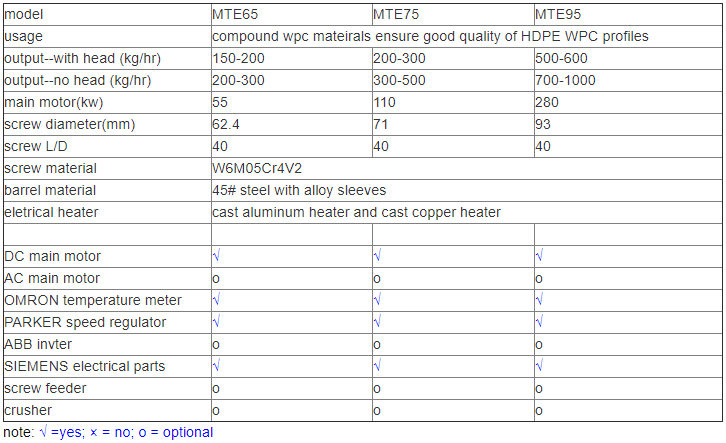

Models of die face hot cutting PE WPC granulation line in MG Machinery: