Plastic film washing machine is used to recycle the waste plastic PE PP films and bags by crushing, washing and drying processing. It has wide usage for kinds of waste plastic films, for example, package films, agricultural films, greenhouse films, plastic shop bags, fresh keeping film bags, garbage bags, hand bags and vest bags, etc.

As usual, a complete plastic film washing line includes different washing machines for different washing purpose, for exmaple, flushing in wet crusher, friction washing by screw friction washer or high speed friction washer washing, rinsing in the floating washing tanks, centrifugal dewatering dehydrator with eletrical heater or squeezer for drying, cyclone storage silo and control cabinet. All the different washing machines will make good washing result for recycling the waste plastic film, so that the recycled clean plastic films can be pelletized for reproduction in extrusion, injection and blowing industries.

1, wet crusher for plastic films

It's a heavy crusher machine working with water for crushing dry or wet plsatic films. the blades mounting is by V shape on the rotor for efficient cutting and crushing the films. And the water spray design can be used to flush parts of dirty while the crushing.

the rotary blades and stationary blades are made of alloy steel, for example, D2, 9CrSi, H13, etc. Sceen sieve is changeable to meet different mateials size requirement. For opening of the top cover, the users can choose screw rod mechanism or hydraulicsystem.

The crusher machine is one of the important unit in the plastic film washing line.

2, friction washers

The friction washer is mainly used for scrubing the dirty plastic films, so that the tough dirty can be washed off easily in the plastic film recycling washing line.

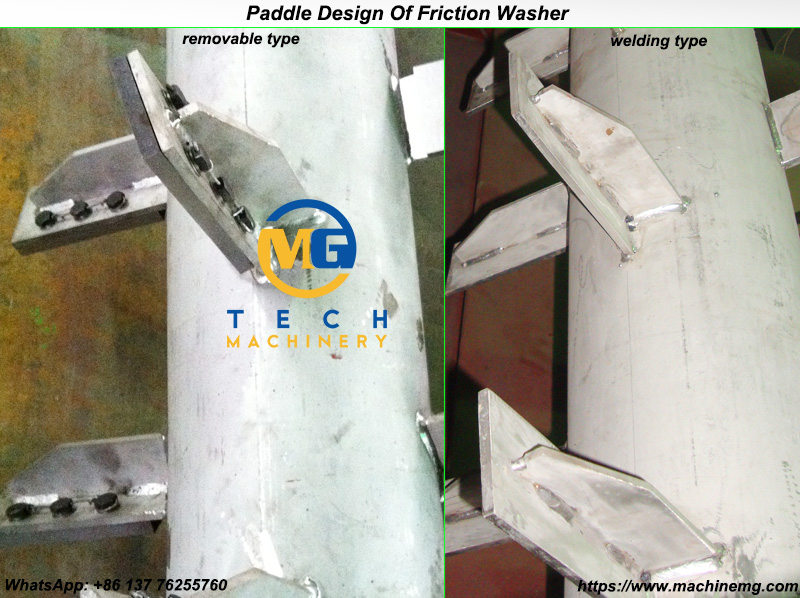

Two types of friction washers are used as usualy, one is the screw friction washer for low speed friction washing and conveying the plastic films. The other one is high speed friction washer for washing tough dirtt mainly on the waste plastic films.

Screw friction washer:

Effective washing length: 4000mm to 4500mm.

Rotation speed: about 600rpm

Paddles, sieve and body are made of stainless steel.

High speed friction washer:

Effective length for washing: 2500mm

Rotation speed: about 1500rpm.

Paddles, sieve and feeding hopper are made of stainless steel.

the paddles could be changeable type, for easy change after wear.

3, floating washing tanks.

The tanks are used for cleaning films, and separate the heavy dirty and materials by different desity. As usually, PE PP films have density less than 1, the solid dirties and some plastic have desity more than 1. While the washing, the PE PP will float on the top of the tank, and be washed by the rollers. And the dirties will sink to bottom, for example, mud, soil, metal and sands, etc.

For the heavy dirty waste plastic films, it is very nessary to incluse 2 or 3 washing tanks in the plastic film washing line.

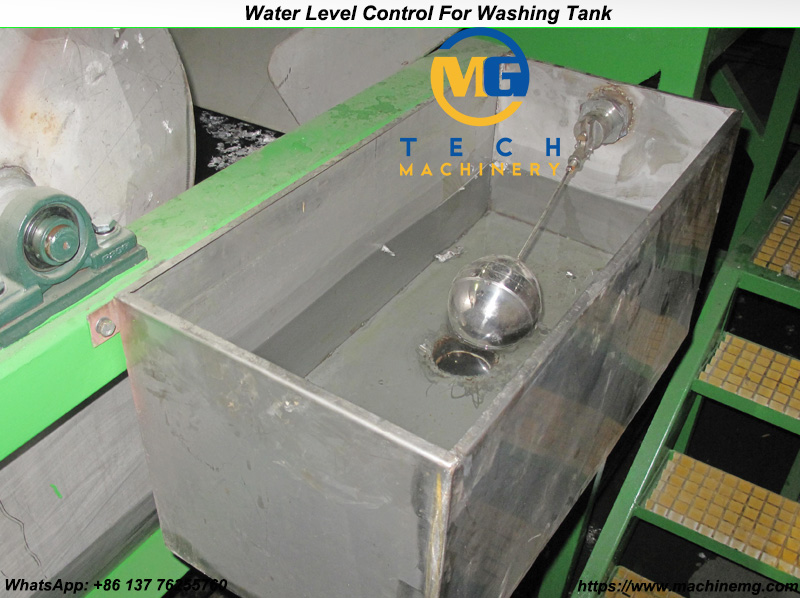

The all parts of the washing tank, contacting with water, are made of stainless steel304.

A ball float valve is designd to the washing tank for the water level control automatically.

4, Dewatering and drying system.

After washing, there are two optional system for dewatering and drying the plastic film materials:

1), Centrifugal dewatering machine and elelctrical heater.

By this system, the centrifugal dewatering machine will spin off the most water content while the high speed roation, then the electrical heater generate hot air for drying the films continuously in the U pipeline.

2), plastic squeezer machine.

This system uses the squeezer to press the plastic films in the barrel by the screw, the water is out from the holes on the barrel.

And the film materials will be squeezed out from a perforated mold, then the cutter cut the mateials into pellet shape or agglomerated material shape.

By the squeezer machine, the film moisture can be less than 5%, and the volume will be reduced 50% at least.

Learn more about the plastic squeezer machine.

5, cyclone system

It is used to store the washed film temporarily, waiting for the packing and transportation.

Silo and pipeline are made of stainless steel.

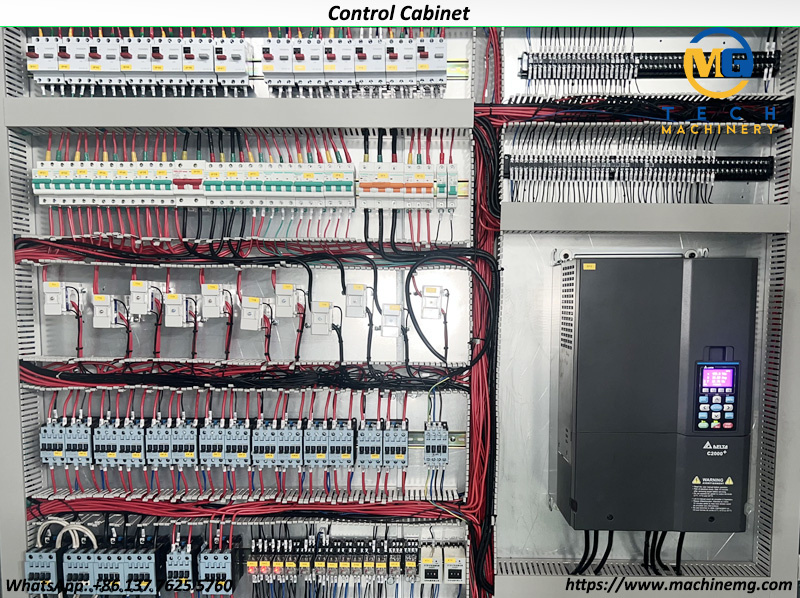

6, Control cabinet

It's centralized control system for each washing machine of the whole plastic film washing line. The user can run and monitor the line easily on the control panel.

For the control cabinet, the good quality electrical components are used, for example, SIEMENS contact, Delta inverter, etc.

Our Plastic film washing lines have the following advantages:

1, high working efficiency, less energy consumption;

2, high automation, labor saving.

3, heavy crusher has SKD-II blades with special mounting angle for efficient cutting, long lifetime. Water spray device for material pre-washing and rotor cooling together.

4, the rinsing tank, screw feeders, pipelines and silo are made of stainless steel.

5, motors and electrical elements are famous brand such as WN and SIEMENS

6, by multiple friction washing and rinsing washing, the dirties can be washed out fully.

7, high dewatering rate by fast speed watering machine or squeezer machine

8, strong machine structure and good balance performance for steady running in long lifetime.

9, reasonable flowchart design for convenient operation and lower maintenance cost.

10, whole solution for sewage water treatment.

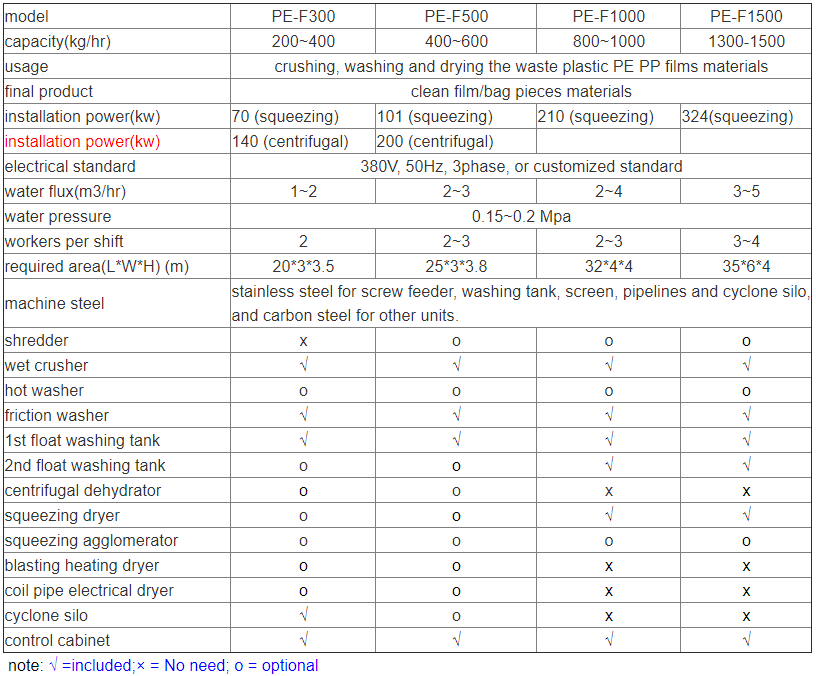

Models of PP PE plastic film washing line in MG Machinery:

Why choose us?

1, provide full solution proposals to meet your requirement.

2, provide machine flowchart and design workshop layout according to your workshop area.

3, high quality level for machine manufacturing.

4, full testing for the machines before shipment.

5, strong production capacity ensures shipment on time.

6, careful machine loading and fixing work in container.

7, dispatch engineer for after sale service in your company on time

8, training for machine and operation.

9, technology support.

10, quality certificate.

etc.

Our plastic recycling machines and extrusion machines have been exported to many countries since 2007, for example, Japan, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Geogia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.