WPC sanding machine is used to sand and smooth the surface of Wood Plastic Composite profiles, the sanded WPC profiles will have the wood alike surface with more market attractiveness. The sanding machine uses abrasive belts to process the surface of WPC profiles, It has two functions, the mainly purpose is to sand off the surface of WPC profiles like a plastic layer, and make the surface be similar to natural wood panels. For more, the sanding process can remove any roughness or imperfections on the surface of the WPC profiles, leaving a smooth and even finish.

The sanding process is an important step in the production of WPC profiles, as it helps to improve the appearance, texture and overall quality of the WPC products.

Additionally, the use of a WPC sanding machine can help to increase the production efficiency of the wood plastic composite, as it can sand larger quantities of WPC profiles in a shorter time than manual sanding methods.

Overall, the WPC sanding machines are essential post processing tools for any manufacturer or producer of wood plastic composite products, as it helps to ensure high quality and consistent results for the WPC plants.

Reference Video of WPC sanding machine on our YouTube Channel:

1, Up surface WPC sanding machine

A WPC sanding machine consists of the following unit:

1, motor driving system.

AC motors are used to drive the abrasive belts and steel roller through CV belts.

2, sanding system.

This type of WPC sanding machine has abrasive belts and steel roller for working together.

Abrasive belt for sanding, and steel roller for brushing to clean the burr.

3, belt conveyor table.

The conveyor uses PVC belt for conveying the WPC profiles into the working chamber for sanding and brushing, then send sanded WPC profiles out automatically. The whole process is continuous.

4, dedusting unit.

Cloth bags are used for collection of powder from the sanding process, and soft pipe are used for the connection between the cloth bags and host of sanding machine.

5, machine frame.

Carbon steel is used to make the machine frame, strong and durable.

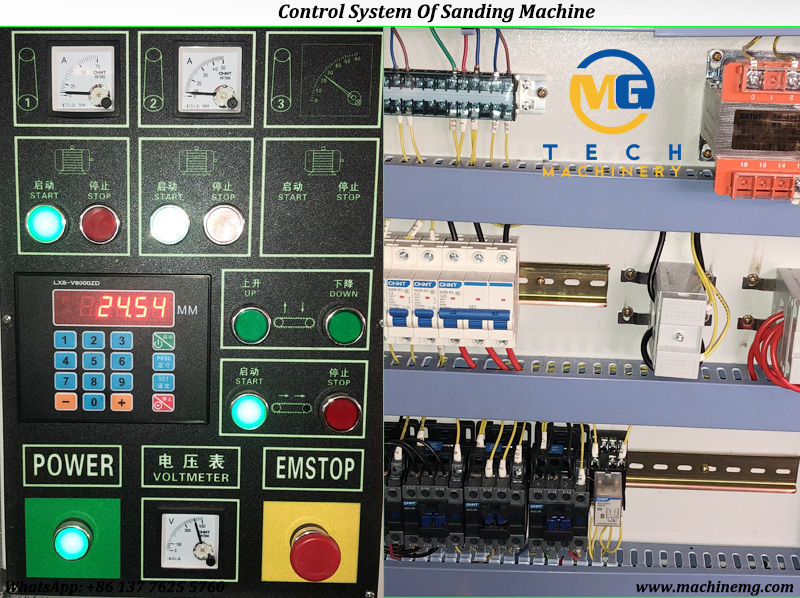

6, control system.

Intelligent meters are installed for digital showing of different processing parameters such as profile thickness for sanding. And independent control is available for abrasive belt and steel roller.

Are you looking for this WPC sanding machine? please send an enquiry for more detail and official quotation.

Advantage of WPC sanding machines in MG:

1, consistent and precise sanding to make a uniform finish across the entire surface of WPC profiles.

2, eliminate some small surface spots on the WPC profiles well.

3, fast processing speed up to 20-30m/min, uniform sanding for WPC profiles.

4, digital meters for processing parameter set and display, it is visual and precise.

5, photoelectric control and protection.

6, working table can be lifted through parameter set according to different profile thickness .

7, sanding firstly by abrasive belt, clean burrs by steel wire rollers after.

8, equipped with pneumatic gun for machine cleaning.

9, equipped with dedusting system for sanding powder collection. avoid powder pollution in the workshop.

10, quality certificate

etc

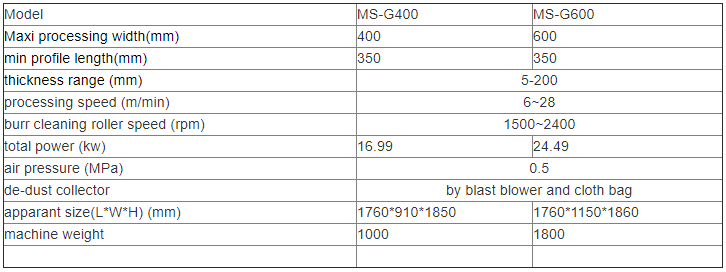

Models of Single surface wpc sanding machine in MG Machinery:

Note: For other width, the WPC sanding machine can be customized.

Why choose us

1, free proposal quotation,

2, free flowchart and layout design.

3, the good processing technics and strict quality control for the machines in China.

4, update information according to production schedule on time.

5, delivery on time.

6, free formula technology support

7, after sale service on time.

8, sharing update technology freely.

Our plastic extrusion machines, auxiliary machines and plastic recycling machines have been exported to many countries since 2007, for example, Japan, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Georgia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.