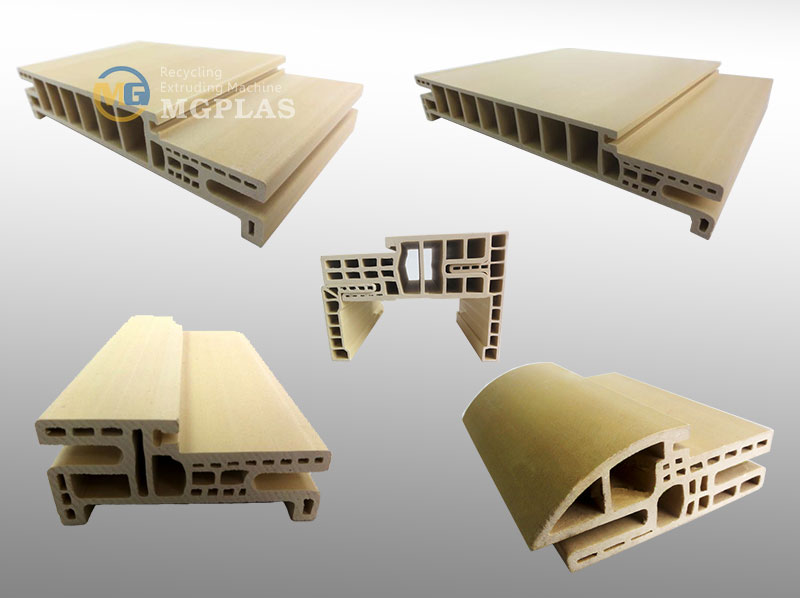

Foamed PVC WPC door frame mould, working with the WPC extrusion line, is used to produce wood plastic composite door frame profiles. the sizes and shapes of different door frame can be customized.

Mould Name: foamed PVC WPC door frame extrusion mould

HS code: 8480790090

Mould component: die head, calibrator, water cooling tank ,heater

Die head steel: 3Cr17MoNiV

Calibrator steel: 3Cr17

Water cooling tank: stainless steel type or

Heater: cast-aluminium

Other Accessories: removable location pins, detachable thread insets, etc.

Other mould steel type for choice: 3Cr13, 3Cr17, 3Cr17MoNiV, din1.2316

Mould cavity: one or multiple cavity by the real mould section design.

Mould surface treatment: Mirror Polish

Production machine: CNC

Extrusion speed: 0.2-2m/min

After-sale service: dispatch engineer to customer's factory for mould commissioning and training.

Value-added service: material formula guidance for improving and optimizing.

Package: Wood /Plywood case(standard export packing)

Lead time: 20 to 30 working days after down payment

Production ability:100 sets of mould per month

Export to: Europe, Middle East, South America, North America, Asia, Africa etc.

Besides the PVC WPC door frame mould, we also supply the PE WPC door frame moulds and PP WPC door frame moulds. The mould size and shape can be customized.

Advantage of foamed PVC WPC door frame extrusion mould in MG Machinery:

1, high quality mould steel.

2, professional mould design engineer can meet different customized requirements.

3, skilled workers with good technique level for mould making.

4, CNC for precision mould manufacturing.

5, professional mould design engineer can meet different customized requirements.

6, mature team for material formula design and mould commissioning.

7, dispatch engineer for mould commissioning quickly.

8, delivery mould on time.

Different sizes and shape can be customized.

Available plastic extrusion mould in MG machinery:

1)Mould for non-foam PE WPC, PP WPC, PVC WPC profiles;

2)Mould for WPC co-extrusion;

3)Mould for PVC+ wood powder surface crusting foaming profile;

4)Mould for PVC low foaming profile, co-extrusion mould for PVC foam decoration profile;

5)Mould for hard PVC door, door panels;

6)mould of color co-extrusion and soft-hard co-extrusion ;

7) Co-extrusion mould for steel-plastic and aluminum-plastic composite;

8) Colors co-extrusion mould for board, wire duct;

9) Mould for PVC quick assembling wallboard;

10) Mould for imitation marble line, door line and water bar.