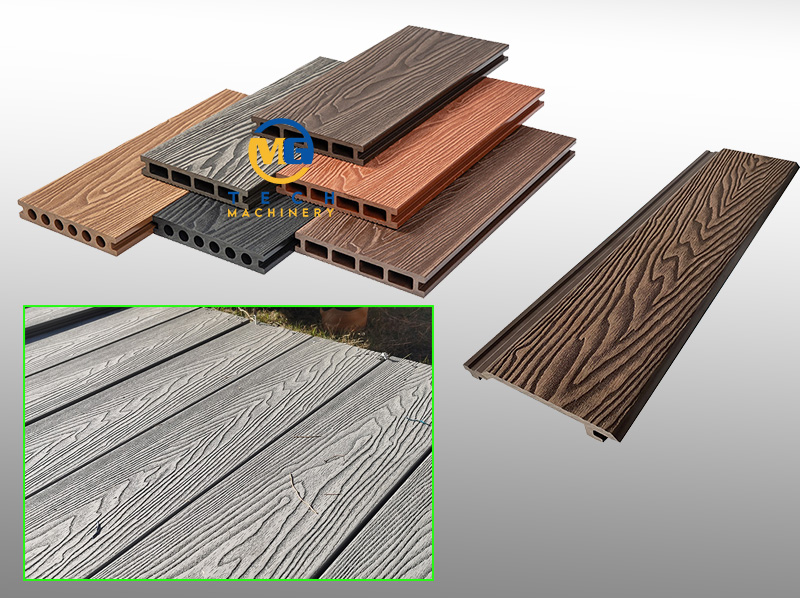

WPC embossing machine is used to create embossed patterns on Wood Plastic Composite profiles. The embossing machine uses heat and pressure to imprint a pattern onto the surface of the WPC profiles, creating a textured and decorative finish. This type of wpc embossing machine is commonly used in the production of WPC decking, wall cladding, fence, pergola and other WPC building materials. The embossing process not only adds aesthetic value to the WPC profiles, but also improves its slip resistance and durability.

Reference Video of WPC embossing machine on our YouTube Channel:

1, single side off line wpc embossing machine.

A WPC embossing machine consists of the following units:

1, driving motor

It's used to drive the embossing roller for working. Small motor is required for such WPC embossing machine.

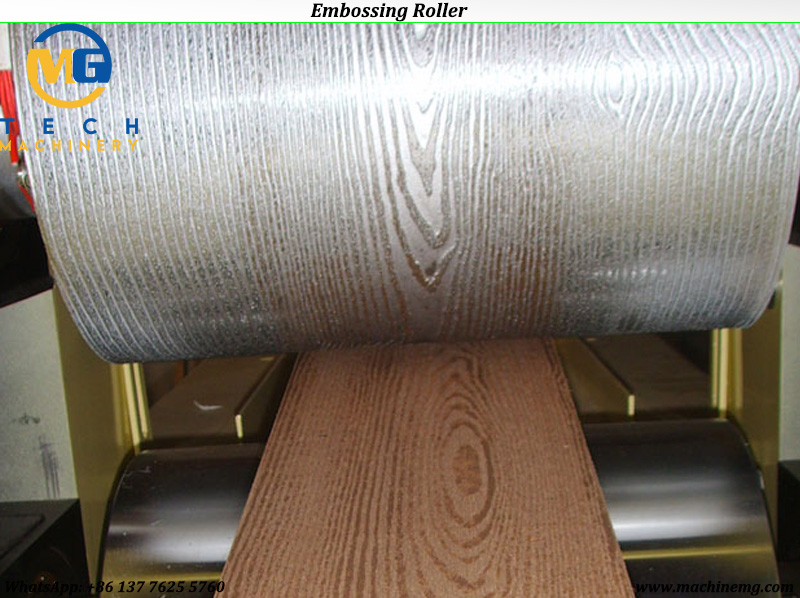

2, embossing roller with bearings.

The embossing rollers are carved with patterns according to the natural wood veins, it could be customized patterns by the provided WPC samples. On both end of the roller shaft, the bearings are equipped for installation on the frame.

Embossing rollers can be customized with different desired patterns for alternative use on the WPC embossing machines.

3, electrical heaters

The WPC embossing machine uses electrical heating rods for the embossing roller, which will help to make easy embossing result on the WPC profiles.

4, machine frame

Strong machine frame is made of 45# steel with good treatment for anti rust and anti corrosion.

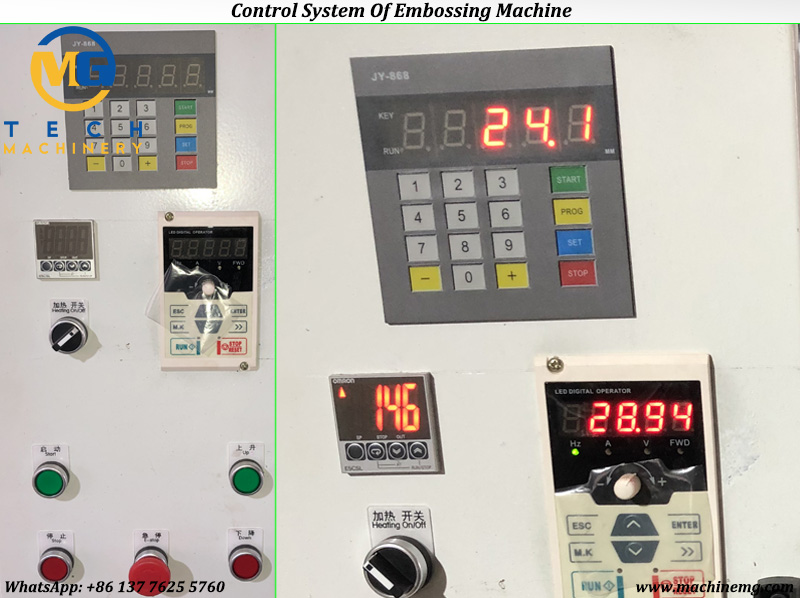

5, digital control system

On the control panel, intelligent meters are installed for digital showing of different processing parameters, for example, gap distance for WPC profiles with different thickness, temperature for embossing and the embossing speed, etc.

As usual, this type of WPC embossing machine is used off line, and It is mainly for 2D embossing on the surface of WPC profiles.

And It will make good surface treatment result for the WPC profiles to have the WPC sanding machine and WPC embossing machine for working together.

With the technology development of wood plastic composite production, We have launched the on line embossing machines for 3D pattern embossing, which can be used for traditional WPC profiles and co extrusion WPC products.

And now we have both single side and double side WPC embossing machine for your choice.

Are you looking for this WPC embossing machine? please send an enquiry for more detail and official quotation.

Advantage of off line WPC embossing machines in MG:

1, embossing rollers are made of 45#40C2 steel.

2, embossing patterns are carved by computer with more precision.

3, patterns are with plating hard chrome treatment for long life on the embossing roller.

4, depth of patterns is about 0.4-0.7mm, embossing depth is adjustable by pressure control between the rollers.

5, fast embossing speed up to 12m/min, speed adjustable.

6, low power consumption, and low noise.

7, strong machine structure.

8, quality certificate.

Etc.

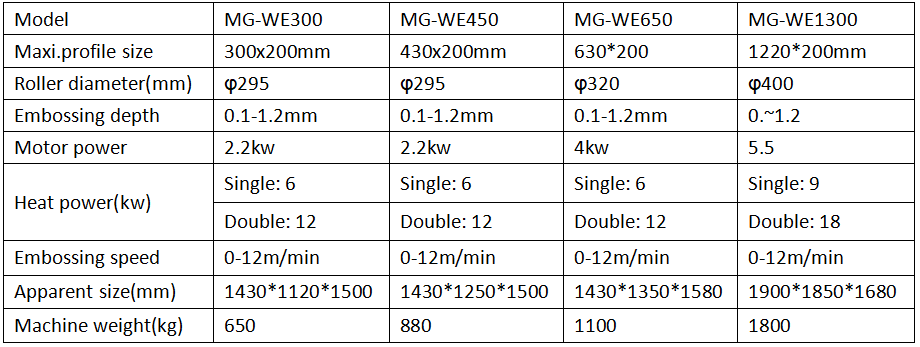

Models of WPC embossing machine in MG Machinery:

Why choose us?

1, provide the whole solution for WPC production. Even from waste plastic recycled if required.

2, professional designs of WPC machine flowchart and workshop layout quickly

3, best quotation for high quality WPC machines from China.

4, high manufacturing technics and strict quality control for WPC machines.

5, complete machine testing well before shipment.

6, shipment on time. And we can help on ship booking, container loading with good fastening in factory

7, dispatch engineer for after sale service on time.

8, training for machine operation in your company.

9, technology support all lifetime.

10, cost price for quick-wearing parts all lifetime.

etc.

Our plastic extrusion machines, auxiliary machines and plastic recycling machines have been exported to many countries since 2007, for example, Japan, Vietnam, Thailand, Malaysia, India, Iran, UAE, Saudi Arabia, Israel, Iraq, Ukraine, Serbia, Georgia, Russia, Kenya, Ghana, Togo, Sudan, USA, Mexico, Chile, Peru, Bolivia, Argentina, etc.