PP PE film water ring pelletizer machine is used to produce plastic pellets from waste plastic PP PE films, It is widely used in the recycling plants, plastic films manufacturing plants, other plants which use package films and bags.

PP PE film water ring pelletizer adopts water-ring die face hot cutting design, the whole line includes cutting compactor, single screw extruder, double station hydraulic screen changer, water-ring pellet cutter, vertical dehydrator, cyclone silo and centralized control cabinet.

The processing of PP PE film water ring pelletizer.

The whole big plastic films and bags can be fed into cutting compactor directly, which has forced crushing and auto feeding function. After plasticizing and degassing through the single screw extruder, the hydraulic screen changer will filter out the impurities, then the plasticized materials are cut into pellets while out from the perforated plate of water-ring cutter, and the pellets are moved with water into dehydrator for dehydrating, finally the pellets are blown into cyclone silo for package.

Machine character

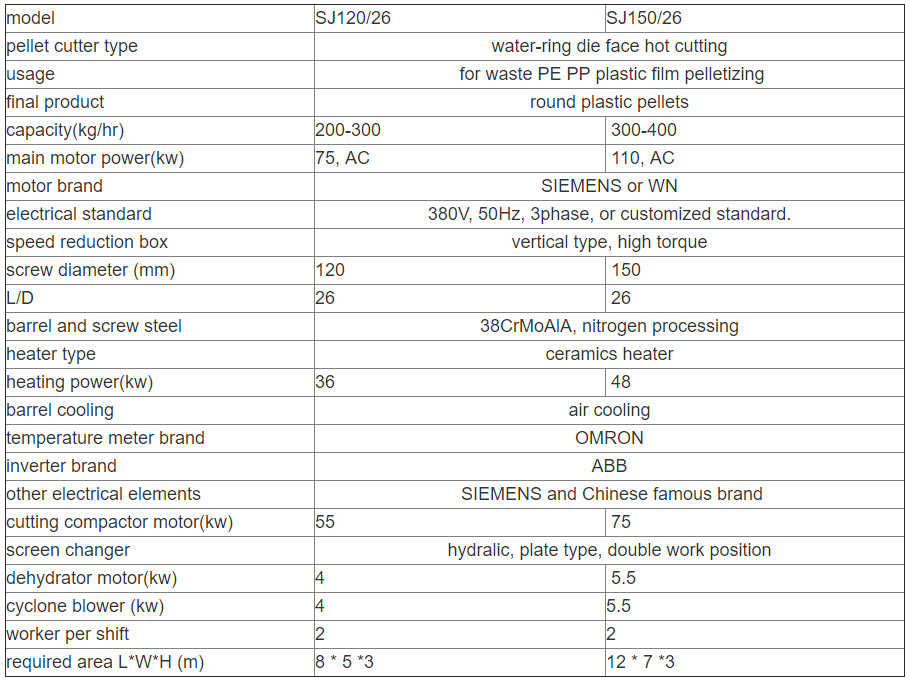

PP PE film water ring pelletizer has the following Characters in MG Machinery:

1, wide usage for kinds of waste PP PE plastic films. Big film pieces, film bags and crushed films can be pelletized directly.

2, barrel and screw are made from 38CrMoAlA steel with nitrogen procession for long lifetime.

3, good plasticizing and degassing performance.

4, famous motors and electrical elements, high quality, steady performance and long life.

5, centralized control system for operation of whole line.

6, easy operation and maintenance, etc.